Amino-functionalized polymer hybrid proton exchange membrane with modified rod-shaped metal organic framework and preparation method of polymer hybrid proton exchange membrane

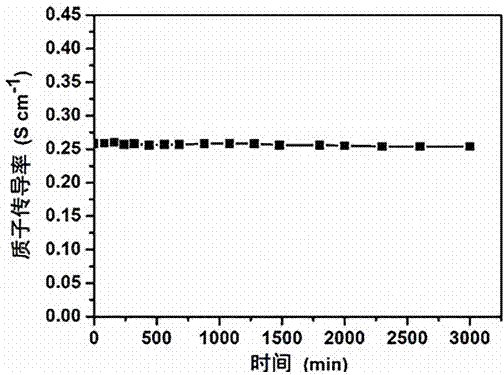

A metal-organic framework and amino functionalization technology, which is applied in electrochemical generators, climate sustainability, final product manufacturing, etc., can solve problems such as unsatisfactory proton conductivity, achieve excellent proton conductivity, strong water retention capacity, Effect of low fuel permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Weigh 3.84 mmolIn(NO 3 ) 3 ·xH 2 O and 1.29 mmol 2-aminoterephthalic acid were added to 12.4 mL N,N-dimethylformamide (DMF), and ultrasonically dispersed into a uniform MIL-68(In)-NH 2 The precursor solution was transferred to a 30 mL polytetrafluoroethylene liner, the lid was closed and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 125 °C for 5 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and an amino-functional rod-shaped metal-organic framework (MIL-68(In)-NH 2 ).

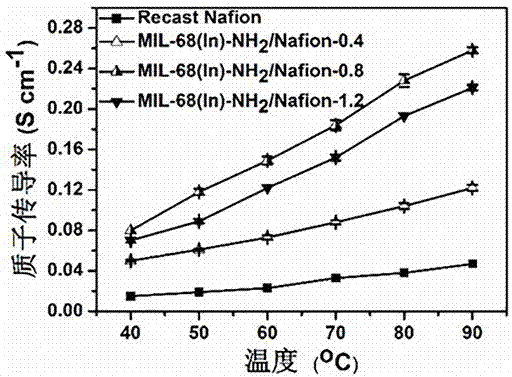

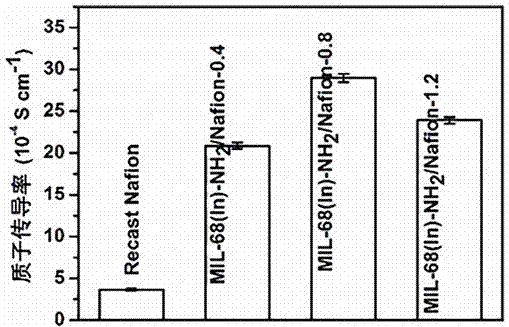

[0024] 2. Take 5mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 1.5mL DMF, and continue rotary evaporation for 10 min. Add 0.4wt% MIL-68(In)-NH to the above Nafion solution 2 , and so...

Embodiment 2

[0027] 1. Weigh 3.84 mmolIn(NO 3 ) 3 ·xH 2 O and 1.29 mmol 2-aminoterephthalic acid were added to 12.4 mL N,N-dimethylformamide (DMF), and ultrasonically dispersed into a uniform MIL-68(In)-NH 2 The precursor solution was transferred to a 30 mL polytetrafluoroethylene liner, the lid was closed and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 125 °C for 5 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and an amino-functional rod-shaped metal-organic framework (MIL-68(In)-NH 2 ).

[0028] 2. Take 5mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 1.5mL DMF, and continue rotary evaporation for 10 min. Add 0.8wt% MIL-68(In)-NH to the above Nafion solution 2 , and so...

Embodiment 3

[0031] 1. Weigh 3.84 mmolIn(NO 3 ) 3 ·xH 2 O and 1.29 mmol 2-aminoterephthalic acid were added to 12.4 mL N,N-dimethylformamide (DMF), and ultrasonically dispersed into a uniform MIL-68(In)-NH 2 The precursor solution was transferred to a 30 mL polytetrafluoroethylene liner, the lid was closed and placed in a reaction kettle to seal tightly, and then placed in a constant temperature oven at 125 °C for 5 h, and the reaction product was centrifuged Separated, first washed with fresh DMF solvent, and then with fresh CH 3 Soak in OH solvent for 3 days, replace with fresh CH twice a day 3 OH solvent, the soaked product was placed in an oven at 50 °C for 6 h, and an amino-functional rod-shaped metal-organic framework (MIL-68(In)-NH 2 ).

[0032] 2. Take 5mL of commercially available Nafion solution, remove about half of the solvent by rotary evaporation, add 1.5mL DMF, and continue rotary evaporation for 10 min. Add 1.2wt% of MIL-68(In)-NH to the above Nafion solution 2 , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Methanol permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com