Advanced treatment and reuse method of biochemical effluent from chemical wastewater

A technology for biochemical effluent and chemical wastewater, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. Easy to handle, reduce toxicity, reduce the effect of effluent toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

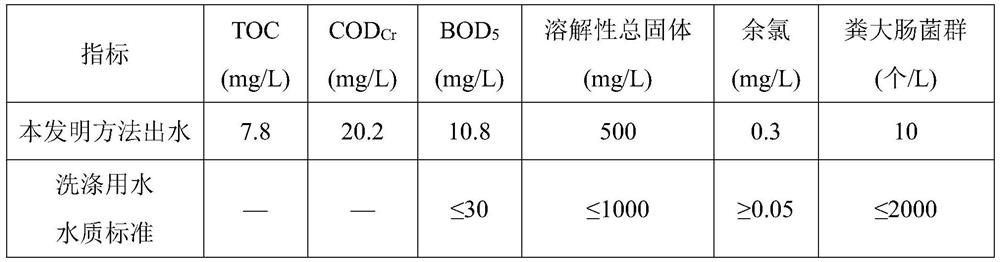

[0028] The biochemical effluent of a large chemical wastewater treatment plant, after adjusting the pH value to 6, added magnetic resin and H to the water sample in sequence 2 o 2 , the volume of magnetic resin accounts for 2% of the volume of chemical wastewater biochemical effluent, H 2 o 2 The concentration was 4 mmol / L, and after 300 minutes of reaction, solid-liquid separation was carried out. Add NaClO disinfectant to the separated chemical wastewater biochemical effluent, press ClO 2 Calculated as 5mg / L, and turn on the 30W ultraviolet lamp to irradiate for 600 seconds at the same time, the water quality of the effluent is shown in Table 1. Finally, the separated magnetic resin is regenerated by mixing with 5wt.% sodium hydroxide and 70wt.% methanol. The regeneration time is 130 minutes, and then left to stand for 55 minutes; the regenerated magnetic resin is used as fresh magnetic resin. As shown in Table 1, taking the water quality standard for washing water in th...

Embodiment 2

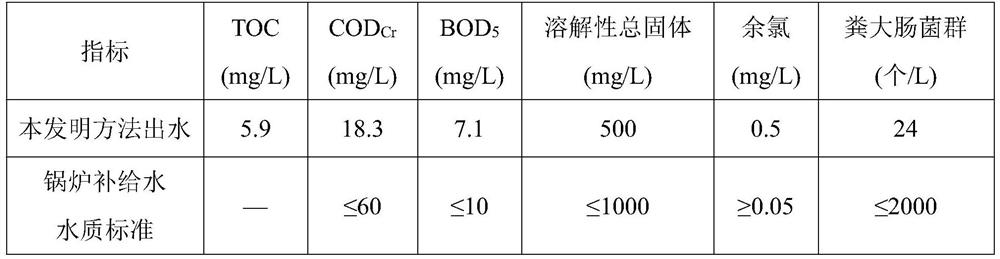

[0032] The biochemical effluent of a large chemical wastewater treatment plant, after adjusting the pH value to 5, added magnetic resin and H 2 o 2 , the volume of magnetic resin accounts for 1.5% of the volume of chemical wastewater biochemical effluent, H 2 o 2 The concentration was 3 mmol / L, and after 100 minutes of reaction, solid-liquid separation was carried out. Add NaClO disinfectant to the separated chemical wastewater biochemical effluent, press ClO 2 Calculated as 5mg / L, and turn on the 30W ultraviolet lamp to irradiate for 120 seconds at the same time, the effluent water quality is as shown in Table 2. Finally, the separated magnetic resin is regenerated by mixing with 15wt.% sodium hydroxide and 20wt.% methanol. The regeneration time is 60 minutes, and then left to stand for 60 minutes; the regenerated magnetic resin is used as fresh magnetic resin. As shown in Table 2, taking the boiler feed water quality standard in Urban Sewage Recycling-Industrial Water Qu...

Embodiment 3

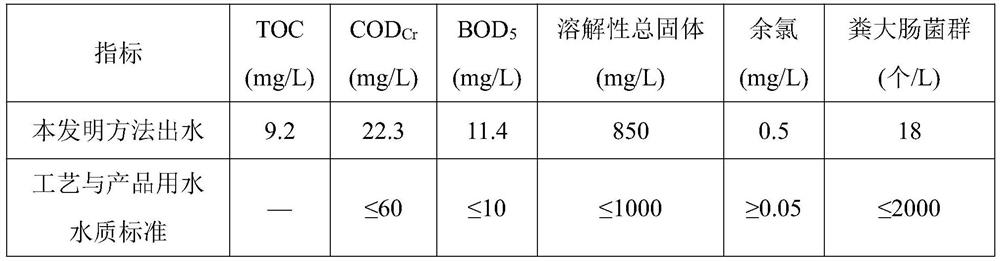

[0036] The biochemical effluent of a large chemical wastewater treatment plant, after adjusting the pH value to 7, added magnetic resin and H to the water sample in sequence 2 o 2 , the volume of magnetic resin accounts for 3% of the volume of chemical wastewater biochemical effluent, H 2 o 2 The concentration was 5 mmol / L, and after 550 minutes of reaction, solid-liquid separation was carried out. Add NaClO disinfectant to the separated chemical wastewater biochemical effluent, press ClO 2Calculated as 5mg / L, and turn on the 30W ultraviolet lamp to irradiate for 1800 seconds at the same time, the water quality of the effluent is shown in Table 3. Finally, the separated magnetic resin is regenerated by mixing with 10wt.% sodium hydroxide and 50wt.% ethanol. The regeneration time is 100 minutes, and then left to stand for 65 minutes; the regenerated magnetic resin is used as fresh magnetic resin. As shown in Table 3, with reference to the water quality standards for process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com