Preparation method alloy-plastic composite shell

A technology of alloy and plastic, which is applied in the field of preparation of alloy-plastic composite housing, and can solve problems such as acid spit and corrosion of oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

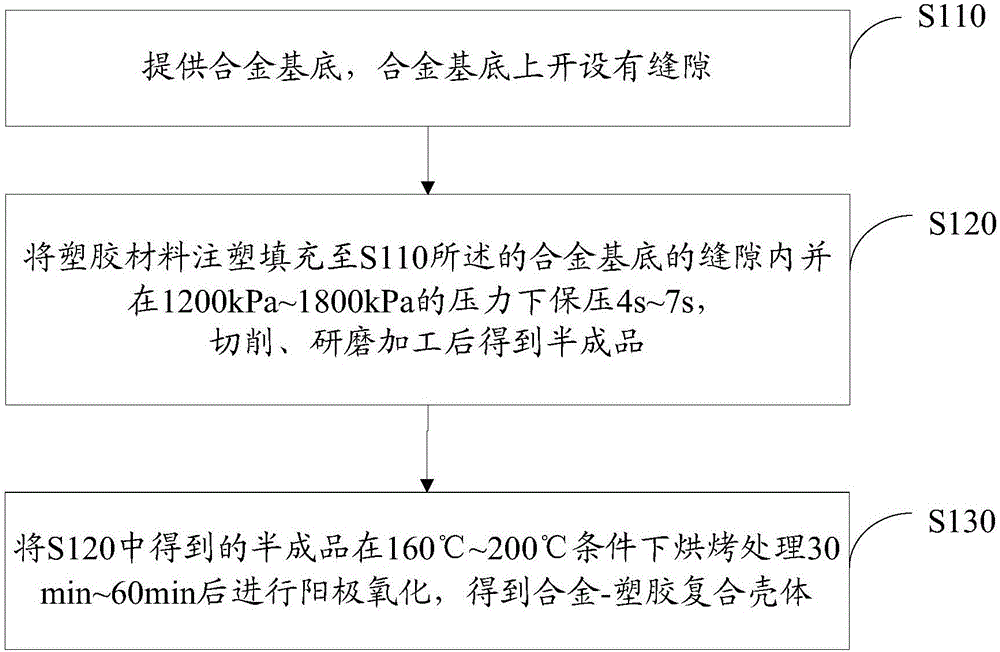

[0021] see figure 1 , The method for preparing an alloy-plastic composite casing according to one embodiment includes the following steps S110-S130.

[0022] S110. An alloy base is provided, and a slit is opened on the alloy base.

[0023] The present invention has no limitation on the material of the alloy substrate, and any alloy containing multiple metal elements can be used as the alloy substrate.

[0024] In this embodiment, the alloy substrate is an aluminum alloy substrate, and the width of the gap is 3 μm˜10 μm. The gap is injected and filled with plastic material to form an alloy-plastic composite shell. Aluminum alloy is cheap, easy to process and shape, and the material is light. It is suitable as the casing of electronic products such as mobile phones and computers.

[0025] Specifically, the slits can be formed on the aluminum alloy substrate by means of laser cutting, electron beam cutting or water cutting.

[0026] S120 , injection molding plastic material i...

Embodiment 1

[0043] A gap of 5 μm is opened on the surface of the aluminum alloy substrate. Fill the polydibutyl terephthalate into the gap by injection molding, and hold the pressure for 5s under the pressure of 1500kPa. During the pressure holding stage, the polydibutyl terephthalate is continuously injected and filled into the gap, and after cutting and grinding, the obtained Semi-finished products, pickling, cleaning liquid cleaning and water washing for semi-finished products. The washed semi-finished product is baked at 180°C for 40 minutes and immediately soaked in the electrolyte. The electrolyte contains 120g / L of concentrated sulfuric acid and 40g / L of oxalic acid. The voltage is 18V and the temperature is 18°C. Under electrolysis, an oxide film is formed on the surface of the semi-finished product to obtain an alloy-plastic composite shell.

Embodiment 2

[0045] A gap of 10 μm is opened on the surface of the aluminum alloy substrate. Fill the gap with polypropylene injection molding, and hold the pressure for 7s under the pressure of 1200kPa. During the pressure holding stage, the polypropylene is continuously injected and filled into the gap, and the semi-finished product is obtained after cutting and grinding. The semi-finished product is pickled, cleaned with cleaning solution and washed with water. The semi-finished product after washing is baked at 160°C for 60 minutes and immediately soaked in the electrolyte. The electrolyte contains 80g / L of concentrated sulfuric acid and 150g / L of oxalic acid , electrolyze under the conditions of voltage 15V and temperature 22°C to form an oxide film on the surface of the semi-finished product to obtain an alloy-plastic composite shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com