Determination method of CO2 displacement minimum miscible pressure of low and ultra-low permeability reservoir

A miscible pressure and measurement method technology, applied in earthwork drilling, wellbore/well components, sustainable manufacturing/processing, etc., can solve the problem of inability to truly reflect miscibility, inability to simulate oil layer conditions, low permeability reservoir permeability Poor performance and other problems, to achieve the effect of true and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

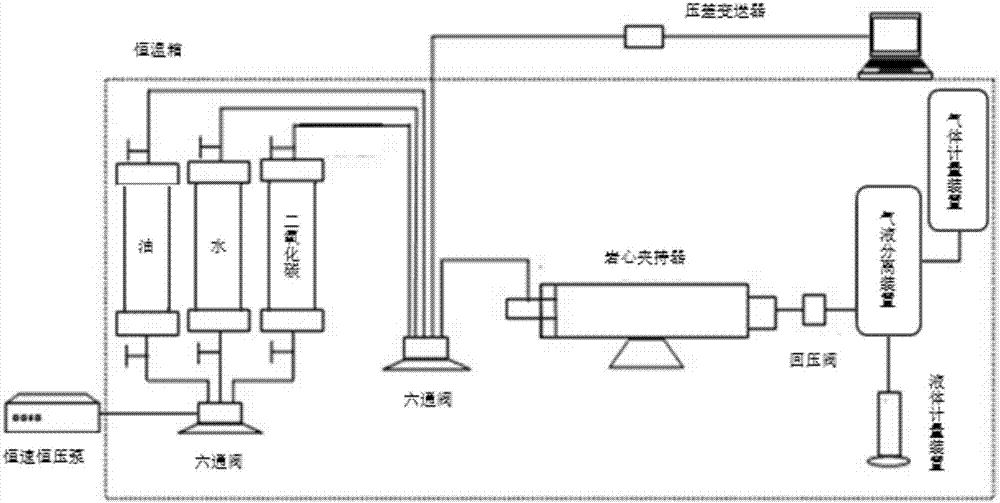

Method used

Image

Examples

Embodiment 1

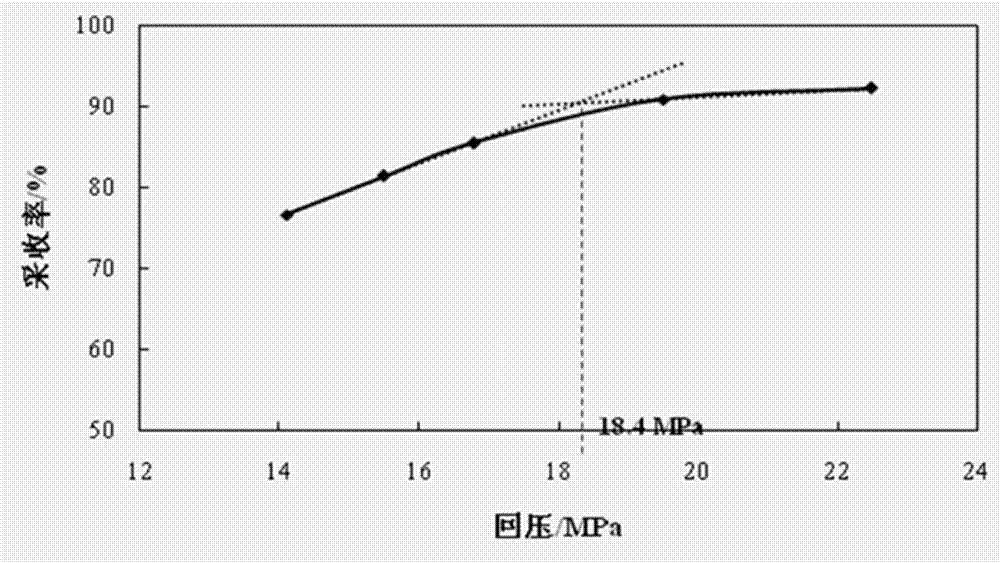

[0058] Adopt a kind of low, ultra-low permeability reservoir CO of the present invention 2 The method for measuring the minimum miscible pressure of flooding, measuring the CO2 in a certain target oilfield block reservoir 2 The flooding minimum miscible pressure includes the following steps:

[0059] 1) A series of artificially pressed ultra-low permeability cores were used as the indoor measurement of CO in (extra) low permeability reservoirs. 2 The physical model core of the minimum miscible pressure is flooded, and the gas permeability of the physical model core is 5×10 -3 μm 2 , the core size is 30×4.5×4.5cm3 , and dry the physical model core, measure the length, width and height of the physical model core, and calculate the apparent volume of the physical model core;

[0060] 2) Carry out anti-corrosion treatment on the physical model core: evenly apply epoxy resin coating on the surface of the physical model core to prevent CO 2 Corrosion of the rubber tube of the co...

Embodiment 2

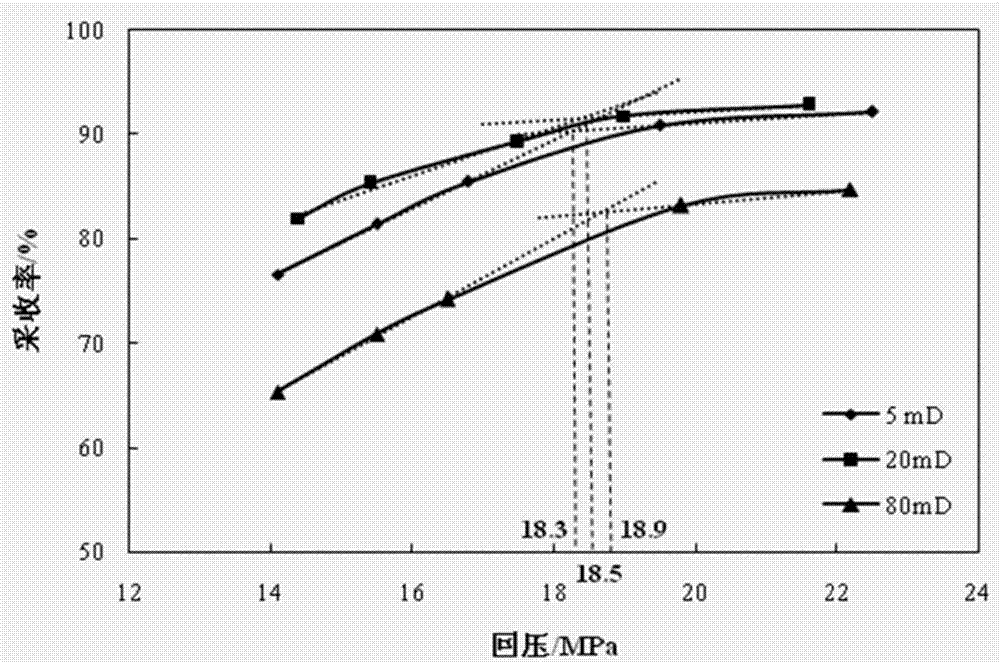

[0082] In this example, the ultra-low permeability cores (gas permeability 5×10 -3 μm 2 ), low-permeability cores (gas permeability 20×10 -3 μm 2 ), medium and low permeability cores (gas permeability 80×10 -3 μm 2 ) as a physical model core, adopt a kind of low, ultra-low permeability reservoir CO of the present invention 2 Determination method of minimum miscibility pressure for flooding CO2 under different permeability conditions 2 and the minimum miscible pressure of formation crude oil, the specific steps are basically the same as in Example 1, and the experimental results of the minimum miscible pressure test of rock cores with different permeability are shown in Table 4; 2 The relationship curve between flooding recovery and back pressure, such as image 3 shown.

[0083] Table 4 CO of different permeability cores 2 Experimental results of flooding minimum miscible pressure test

[0084]

[0085] From Table 4 and image 3 The following conclusions can be dr...

Embodiment 3

[0089] In this example, homogeneous rock cores (gas permeability 5×10 -3 μm 2 ), heterogeneous cores with a permeability difference of 10 (the permeability of the low permeability layer is 5×10 -3 μm 2 , High permeability layer permeability 50×10 -3 μm 2 ), heterogeneous cores with a permeability difference of 30 (the permeability of the low-permeability layer is 5×10 -3 μm 2 , high permeability layer permeability 150×10 -3 μm 2 ) as a physical model core, adopt a kind of low, ultra-low permeability reservoir CO of the present invention 2 Determination method of minimum miscibility pressure for flooding Test different degrees of heterogeneous core CO2 The minimum miscible pressure with formation crude oil, the specific steps are basically the same as in Example 1, and different degrees of heterogeneous core CO 2 Table 5 shows the experimental results of flooding minimum miscible pressure; 2 The relationship curve between flooding recovery and back pressure, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com