Detection method for viscosity of continuous-casting casting slag

A technology of continuous casting casting and detection method, which is applied in the detection of continuous casting casting slag viscosity and detection field of casting slag viscosity. , low labor intensity, and the effect of narrowing the fluctuation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

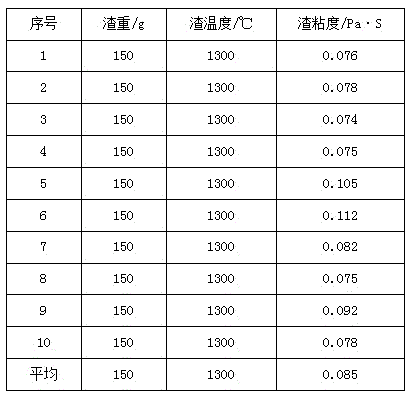

[0018] The present invention will be further described below in conjunction with embodiment. In the embodiment, the casting slag whose origin is Henan and whose number is BA019-14 / M1001 is selected. The main chemical components of the casting slag are shown in Table 1.

[0019] Table 1 Chemical composition of pouring slag in the embodiment of the present invention, unit: weight percent

[0020]

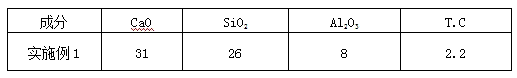

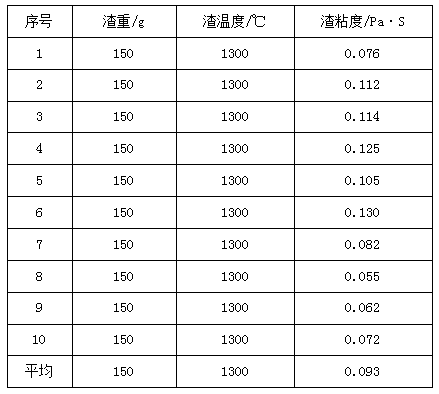

[0021] A method for detecting the viscosity of continuous casting slag, comprising the following steps:

[0022] 1) Use dimethyl silicone oil as the standard liquid to calibrate the instrument constant K value of the model ND-II slag viscometer at 20°C;

[0023] 2) Put 150g of decarburized and continuous casting slag into the graphite crucible with an inner diameter of 40mm, put the graphite sleeve and graphite crucible into the slag viscometer, raise it to 1300°C, and keep it at this temperature for 30min;

[0024] 3) Drop the Φ14×22mm high-purity metal molybdenum probe from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com