Flexible electronic device and manufacturing method thereof

A technology of flexible electronic devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, electrical components and other directions, can solve problems such as explosion, flexible substrate circuit failure, and flexible substrate barrier performance degradation, and achieve effective guarantees. performance, low equipment cost, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

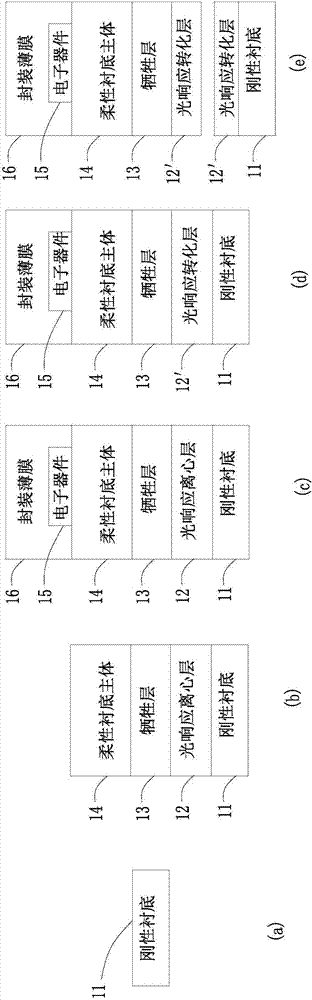

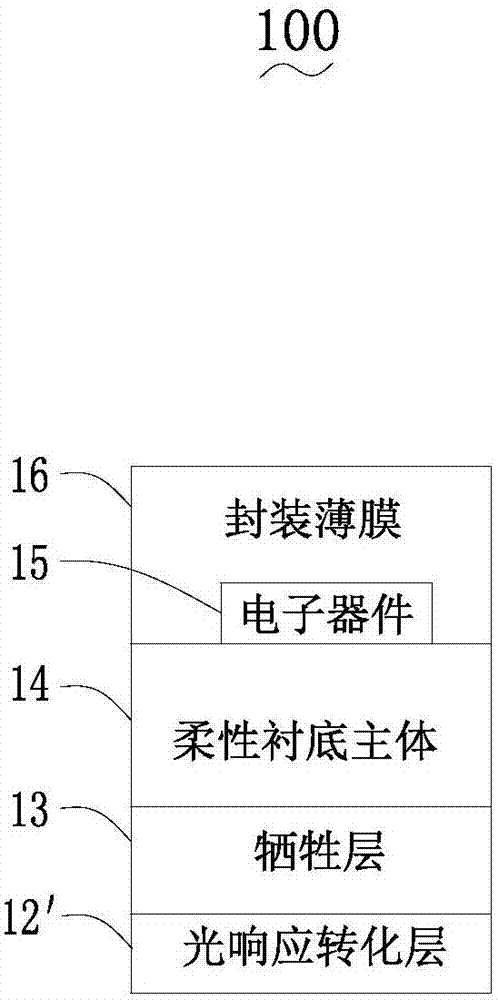

[0037] see figure 1 , is a process flow chart of the manufacturing method of the flexible electronic device provided by the present invention. The manufacturing method of the flexible electronic device comprises the steps of:

[0038] Step S1: providing a rigid substrate 11, on which a photoresponsive release layer 12, a sacrificial layer 13 and a flexible substrate body 14 are sequentially formed (see figure 1 (a), (b));

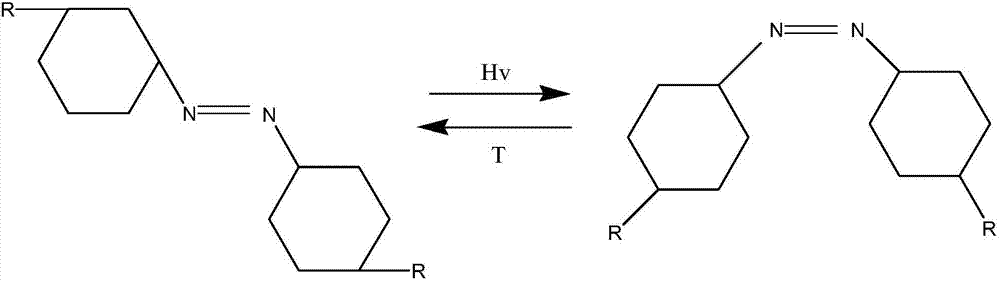

[0039] Specifically, by coating the precursor of the photoresponsive release layer 12 on the rigid substrate 11, and then curing at a high temperature to form the photoresponsive release layer 12 of the trans isomer structure; Depositing and forming the sacrificial layer 13 on the photoresponsive release layer 12; then manufacturing and molding the flexible substrate main body 14 sequentially according to conventional LED technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com