Depilatory preparation method

A depilatory and additive technology, applied in the field of depilatory preparation, can solve the problems of paraffin wax lack of toughness, unsatisfactory adhesion performance, brittle and brittle, etc., and achieve easy popularization, low production condition requirements, and good thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 48 parts by weight of paraffin, 36 parts of microcrystalline paraffin, 16 parts of polyethylene wax and 4 parts of maleic anhydride are added to the reactor for heating and melting, feed N2 for protection, add 0.28 parts of di-tert-butyl peroxide, and heat up to Stir at 156°C at a speed of 40r / min, react for 90min, and obtain modified paraffin.

[0023] Put 2g of modified paraffin into a flask containing 70ml of xylene, heat to reflux, pour the mixed solution containing modified paraffin into excess acetone to precipitate grafts, filter with suction and dry in vacuum to obtain purified modified paraffin (Unreacted maleic anhydride monomer or polymer has been removed).

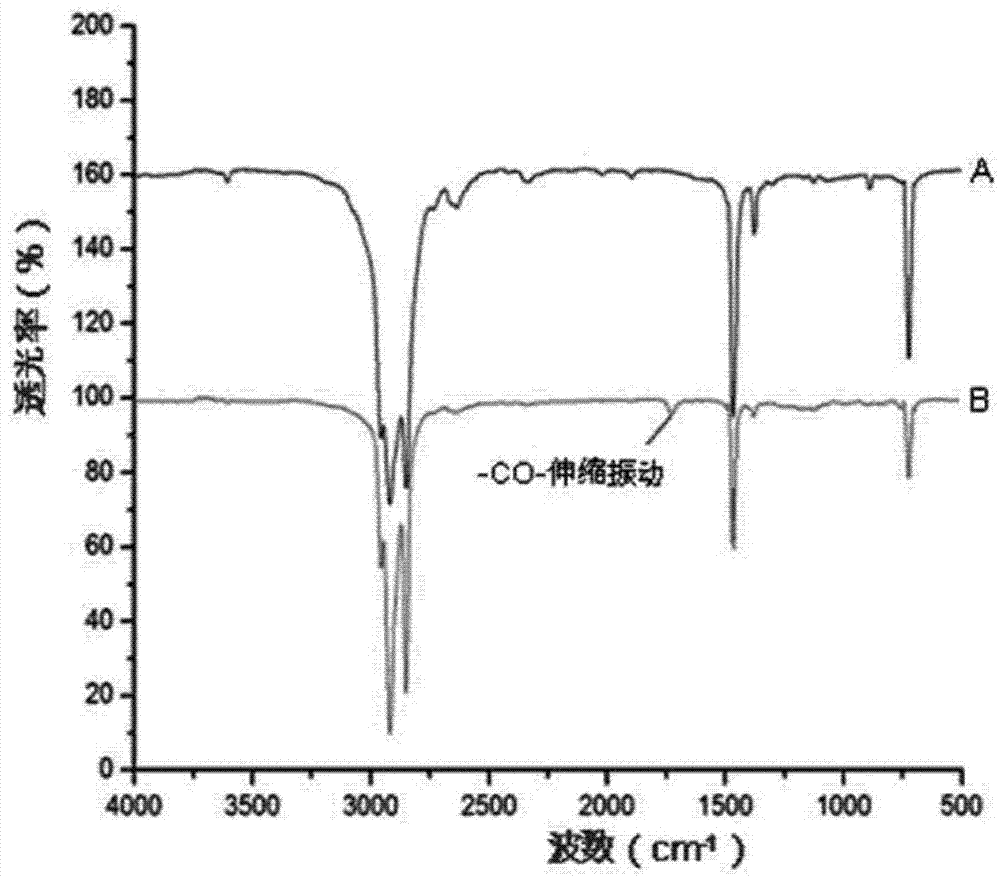

[0024] Take the paraffin wax mixture and the modified paraffin wax after purification for infrared spectrum analysis respectively, see figure 1 Shown: In the figure, curve A represents the paraffin wax mixture, and curve B represents the modified paraffin after purification.

[0025] Depend on figure ...

Embodiment 2

[0028] Add 55 parts of paraffin wax, 38 parts of microcrystalline paraffin wax, 7 parts of polyethylene wax and 6 parts of maleic anhydride into the reaction kettle, heat and melt, pass through N2 protection, add 0.36 parts of tert-butyl hydroperoxide, and raise the temperature to 142°C , stirred at a speed of 75r / min, reacted for 75min; lowered the temperature to 135°C, added 0.30 parts of calcium stearate and 6 parts of calcium carbonate, stirred at a speed of 80r / min, melted and blended for 35 minutes, cooled and discharged to obtain the product , and its melting temperature is 72°C.

Embodiment 3

[0030] Add 43 parts of paraffin wax, 48 parts of microcrystalline paraffin wax, 9 parts of polyethylene wax and 3 parts of maleic anhydride into the reaction kettle to heat and melt, pass through N2 protection, add 0.26 parts of tert-butyl hydroperoxide, and raise the temperature to 148°C , stirred at a speed of 60r / min, and reacted for 100min; lowered the temperature to 140°C, added 0.35 parts of calcium stearate and 3 parts of calcium carbonate, stirred at a speed of 65r / min, melted and blended for 30 minutes, cooled, and discharged to obtain the product , and its melting temperature is 75°C.

[0031] In order to verify the dosage range and temperature range of each component in the claims, a large number of application examples have been completed, and Table 1 is the relevant information of some examples.

[0032] Table 1 Process parameters, conditions and product melting temperature of some embodiments*

[0033]

[0034] *The unit of each reaction material is parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap