Beef and mutton chafing dish bottom material and production technology thereof

A technology for hot pot base material and beef and mutton, which is applied in the field of food processing, can solve the problems of strange taste, influence the taste of hot pot, poor control of the heat of the hot pot base material, etc., and achieve the effect of unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

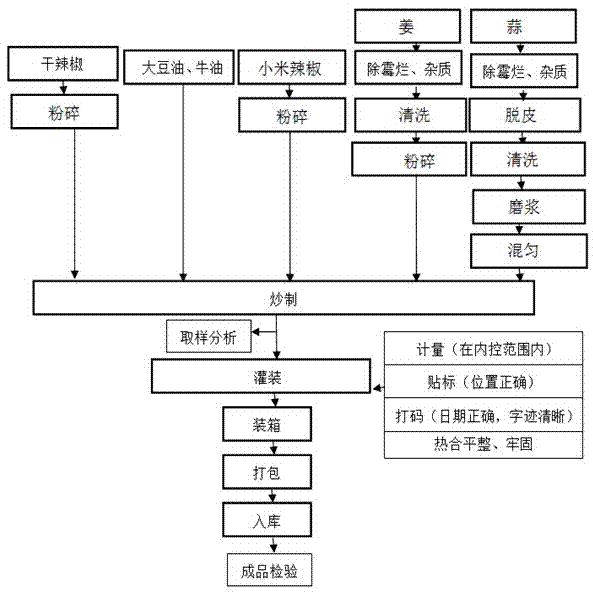

Method used

Image

Examples

Embodiment 1

[0027] In the embodiment of the present invention, a beef and mutton hot pot bottom material is made of the following raw materials in terms of parts by mass: 30g of butter, 8g of soybean oil, 6g of bullet pepper, 8g of millet pepper, 2g of ginger, and 1g of garlic. 7g salt, 1g white sugar, 70g bean paste, 0.3g pepper, 2g tempeh, 2g soy sauce, 4g diced mushroom, 0.6g wolfberry, 1 red date, 0.4g lotus seeds, 0.8g hot pot spice, 0.08g lemongrass, 2g monosodium glutamate, Liquor 1.0g, gardenia powder 0.15g, cumin 0.15g, 5'-flavored nucleotide disodium 0.10g, potassium sorbate; the amount of potassium sorbate added is based on sorbic acid 0.04g; Doubanjiang is processed according to the mass ratio of watercress and pepper of 2:8. In terms of parts by mass, the hot pot spice is made of the following raw materials: 8 grams of cumin, 8 grams of cardamom, 8 grams of cinnamon, 8 grams of star anise, 7 grams of fragrant fruit, 7 grams of grass fruit, 7 grams of coriander seeds, and 7 gr...

Embodiment 2

[0029] In the embodiment of the present invention, a beef and mutton hot pot bottom material is made of the following raw materials in terms of parts by mass: 50g of butter, 12g of soybean oil, 10g of bullet pepper, 12g of millet pepper, 4g of ginger, and 3g of garlic, eaten 11g salt, 3g white sugar, 110g bean paste, 0.5g pepper, 4g tempeh, 4g soy sauce, 6g diced mushrooms, 1.0g wolfberry, 3 red dates, 0.6g lotus seeds, 1.2g hot pot spices, 0.12g lemongrass, 4g monosodium glutamate, Liquor 2.0g, gardenia powder 0.25g, cumin 0.25g, 5'-flavored nucleotide disodium 0.20g, potassium sorbate; wherein the amount of potassium sorbate added is based on sorbic acid 0.06g; Doubanjiang is processed according to the mass ratio of watercress and pepper of 2:8. In terms of parts by mass, the hot pot spice is made of the following raw materials: 8 grams of cumin, 8 grams of cardamom, 8 grams of cinnamon, 8 grams of star anise, 7 grams of fragrant fruit, 7 grams of grass fruit, 7 grams of cor...

Embodiment 3

[0031] In the embodiment of the present invention, a beef and mutton hot pot bottom material is made of the following raw materials in terms of parts by mass: 30g of butter, 12g of soybean oil, 6g of bullet pepper, 12g of millet pepper, 2g of ginger, and 3g of garlic. 7g salt, 3g white sugar, 70g bean paste, 0.5g pepper, 2g tempeh, 2g soy sauce, 4g diced mushroom, 1.0g wolfberry, 1 red date, 0.6g lotus seed, 0.8g hot pot spice, 0.12g lemongrass, 2g monosodium glutamate, Liquor 2.0g, gardenia powder 0.15g, cumin 0.25g, 5'-flavored nucleotide disodium 0.10g, potassium sorbate; wherein the amount of potassium sorbate added is based on sorbic acid 0.06g; Doubanjiang is processed according to the mass ratio of watercress and pepper of 2:8. In terms of parts by mass, the hot pot spice is made of the following raw materials: 8 grams of cumin, 8 grams of cardamom, 8 grams of cinnamon, 8 grams of star anise, 7 grams of fragrant fruit, 7 grams of grass fruit, 7 grams of coriander seeds,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com