Toothpaste suitable for pump-type packing material and preparation method thereof

A technology for toothpaste and packaging materials, applied in the field of toothpaste, can solve the problems of low viscosity of paste, unsightly appearance of hoses, and difficulty in effectively transferring drugs to teeth, etc., and achieves good fluidity, excellent shear thinning and touch. The effect of denaturation and formulation composition optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

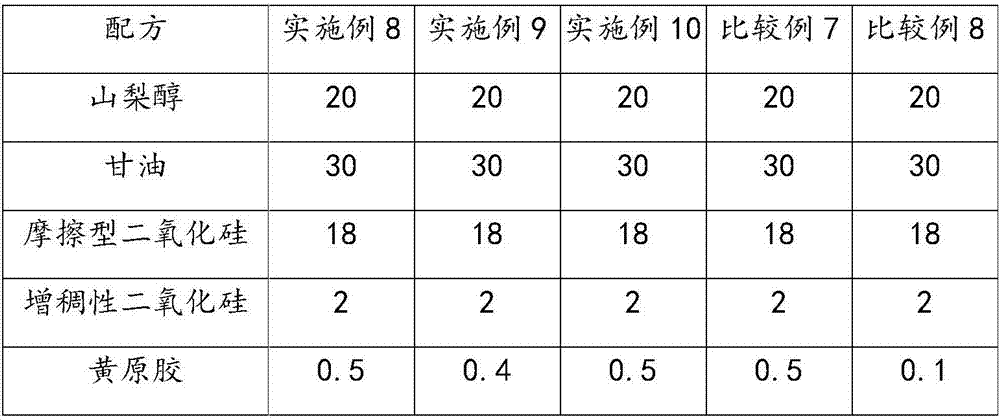

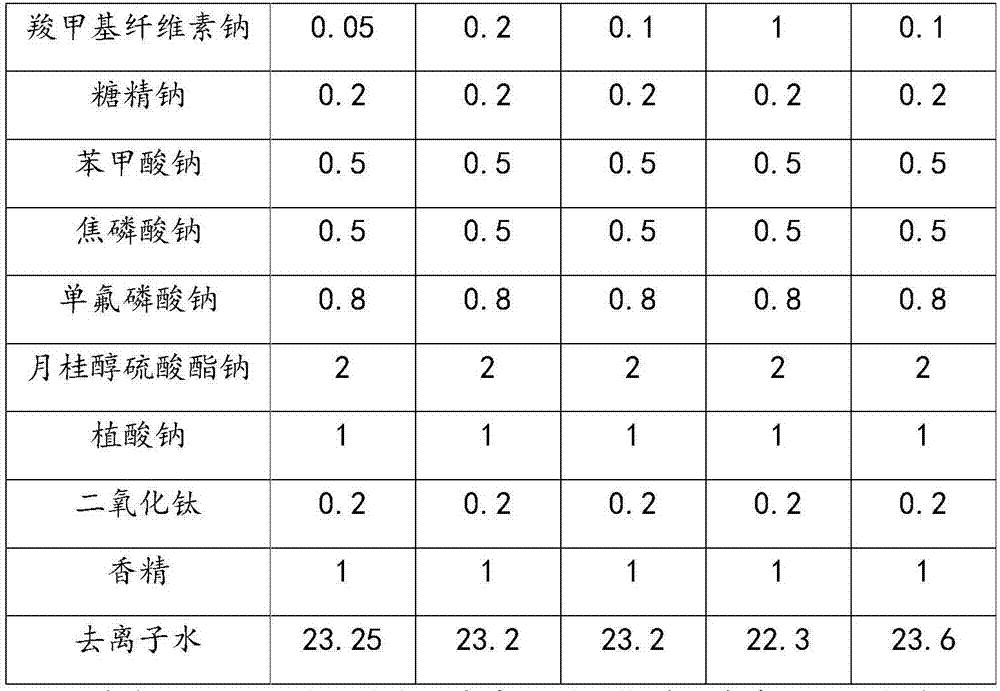

[0041] Embodiment 1~10 is the concrete embodiment of toothpaste of the present invention, and comparative example 1~8 is comparative test, and the formula component of embodiment 1~10 and comparative example 1~8 is the same, and preparation method is the same, only the consumption of certain formula Not the same, the concrete formula of each embodiment and consumption thereof are as shown in table 1, table 2 and table 3, and the preparation method of each embodiment comprises the following steps:

[0042] step 1

[0043] Add taste improver, stabilizer, preservative and functional ingredients to deionized water, stir at a speed of 1000r / min, and stir for 15 minutes until the raw materials are dissolved to prepare an aqueous solution; the taste improver is sodium saccharin, and the stabilizer is pyrophosphoric acid Sodium, the preservative is sodium benzoate, and the functional ingredients are sodium monofluorophosphate and sodium phytate;

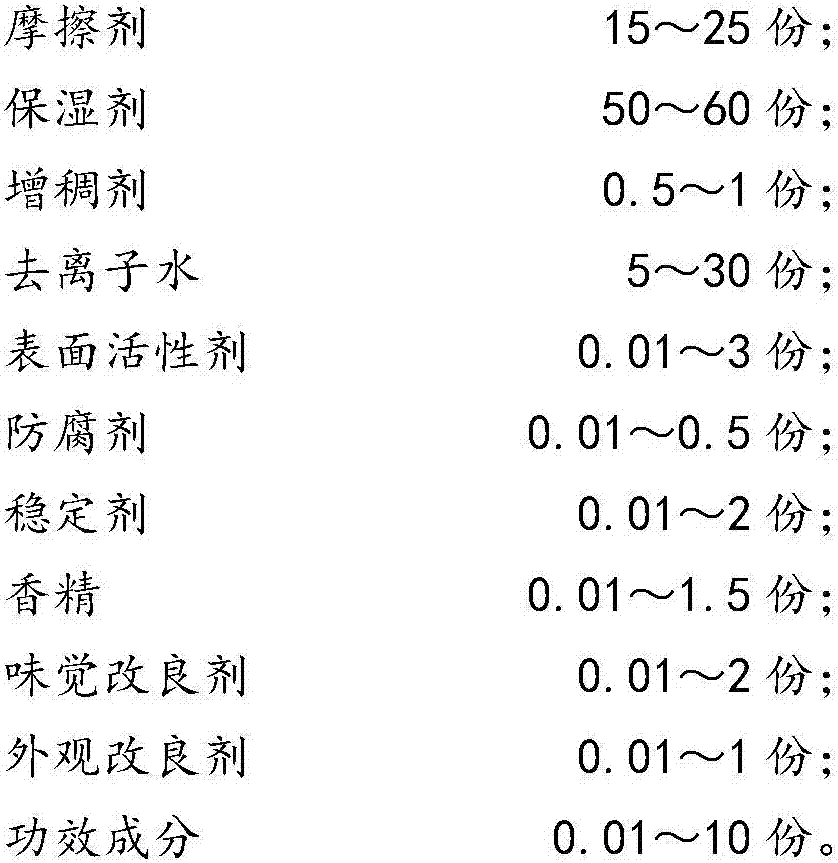

[0044] Add a thickener to the humect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com