Method for surface modification of graphene by rare earth

A surface modification, graphene technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of poor dispersion, burning loss, poor matrix compatibility, etc., to improve the modification efficiency and modification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a. Under the condition of 298K, prepare 10mL mixed acid solution A with a volume ratio of 78% concentrated nitric acid and 98% concentrated sulfuric acid;

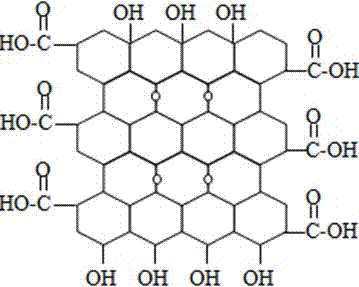

[0035] b. Weighing 1.2g of graphene and adding it to the mixed acid solution A for soaking for 1h, and performing surface roughening treatment to generate oxygen-containing groups such as hydroxyl, carboxyl, and epoxy groups on the surface of graphene, and then undergo multiple centrifugation , the speed of centrifugation is accelerated successively, then filtered, and then washed with deionized water for several times until the pH value is neutral, and dried at 80°C for 12 hours to obtain graphene with a roughened surface. The molecular structure of graphene is as follows figure 1 shown;

[0036] Wherein the multiple centrifugation speeds described in step b are divided into the following stages:

[0037] The rotation speed of 1~2 times of centrifugation is 2000~3500 r / min, and the time is 20~40min;

[0038] The...

Embodiment 2

[0048] a. Under the condition of 298K, prepare 15mL mixed acid solution A with 78% concentrated nitric acid and 98% concentrated sulfuric acid at a volume ratio of 1:2;

[0049] b. Weighing 1g of graphene is added to the mixed acid solution A and soaked for 2h, and the surface is roughened to make the surface of graphene generate oxygen-containing groups such as hydroxyl, carboxyl, epoxy, etc., and then through multiple centrifugation, The speed of centrifugation is accelerated successively, then filtered, and then washed with deionized water for several times until the pH value is neutral, and dried at 90°C for 18 hours to obtain graphene with a roughened surface, which is ready for use;

[0050] Wherein the multiple centrifugation speeds described in step b are divided into the following stages:

[0051] The rotation speed of 1~2 times of centrifugation is 2000~3500 r / min, and the time is 20~40min;

[0052] The speed of centrifugation for 3~4 times is 3500~5000 r / min, and t...

Embodiment 3

[0060] a. Under the condition of 298K, prepare 20mL mixed acid solution A with 78% concentrated nitric acid and 98% concentrated sulfuric acid at a volume ratio of 1:3;

[0061] b. Weigh 1.3g of graphene and add it to the mixed acid solution A to soak for 3 hours, and carry out surface roughening treatment, so that oxygen-containing groups such as hydroxyl, carboxyl, and epoxy groups are generated on the surface of graphene, and then undergo multiple centrifugal treatments , the speed of centrifugation is accelerated in turn, then filtered, and then washed with deionized water for several times until the pH value is neutral, and dried at a temperature of 100°C for 20 hours to obtain roughened graphene, which is set aside;

[0062] Wherein the multiple centrifugation speeds described in step b are divided into the following stages:

[0063] The rotation speed of 1~2 times of centrifugation is 2000~3500 r / min, and the time is 20~40min;

[0064] The speed of centrifugation for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com