Synthetic method of linaclotide

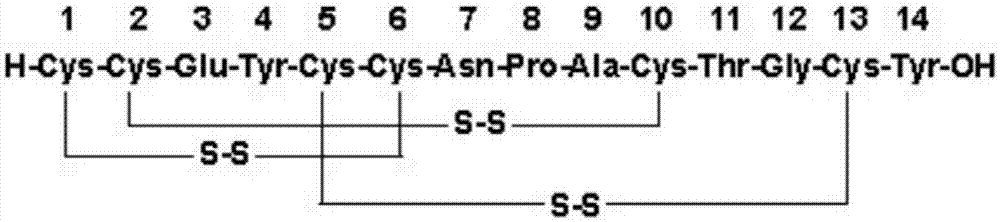

A technology of linaclotide and synthetic method, which is applied in the field of drug synthesis, can solve the problems of low product purity and yield, and achieve the effects of low cost, simple operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

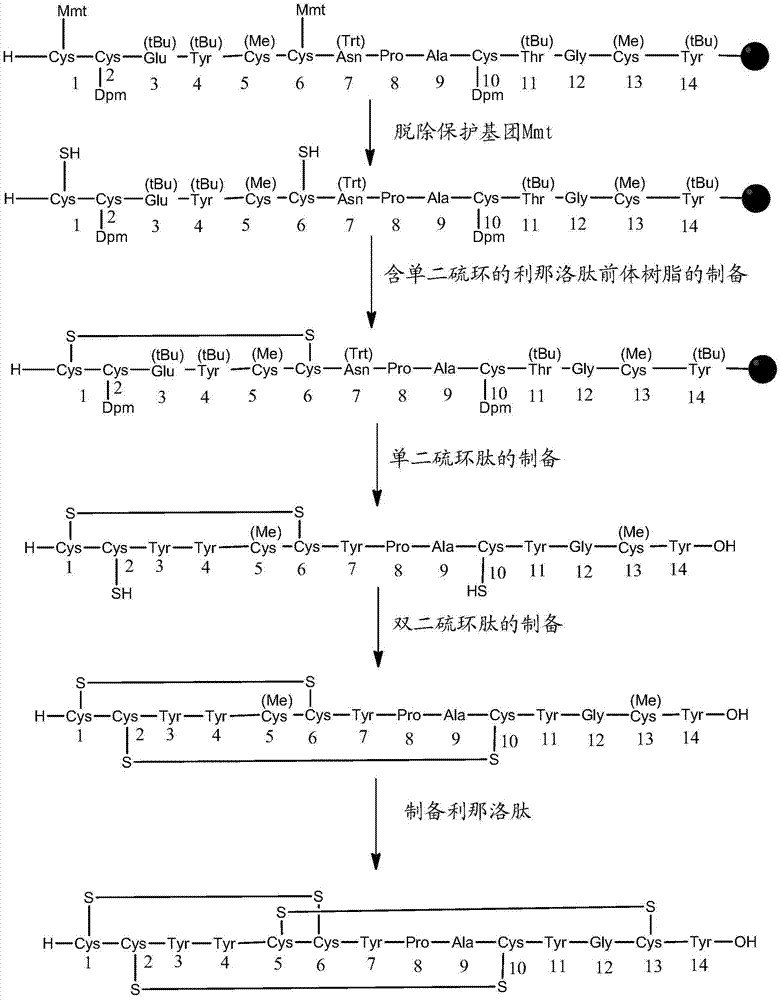

Method used

Image

Examples

Embodiment 1

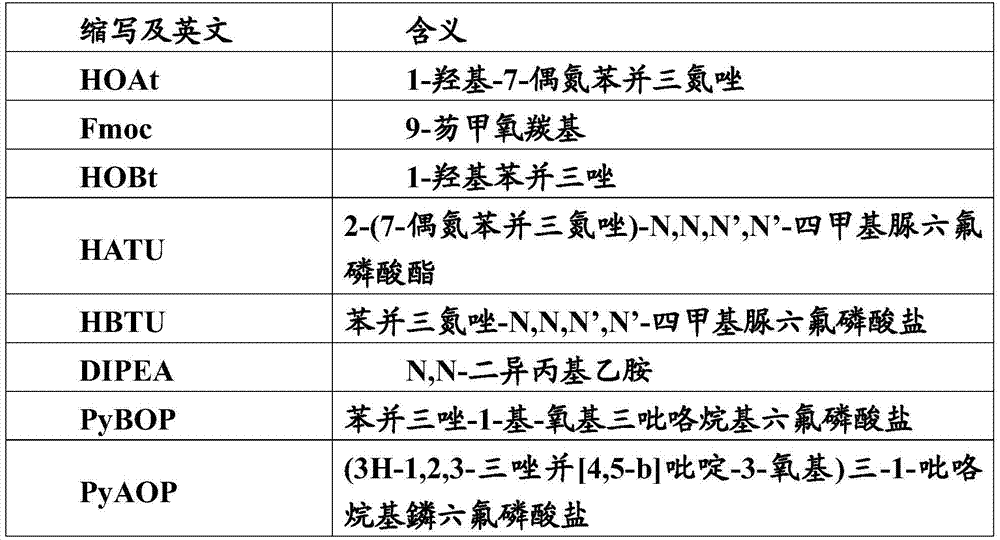

[0047] Embodiment 1: the degree of substitution is the preparation of 0.50mmol Fmoc-Tyr(tBu)-Wang resin

[0048] Take by weighing Wang resin 100g that the degree of substitution is 1.0mmol / g in the solid phase reaction column, add 150ml DMF, nitrogen bubbling swelling 60 minutes; Weigh Fmoc-Tyr (tBu)-OH (45.9g, 100mmol), HOBt ( 16.2g, 120mmol), DMAP (1.2g, 10mmol), dissolved in 100ml DMF, added DIC (20.3ml, 117.1mmol) at 0°C, activated for 5 minutes, and added to the reaction column. After two hours of reaction, acetic anhydride (70ml) and pyridine (60ml) were added, mixed and blocked for 24 hours, and washed with DCM 3 times (100ml / time). The resin was shrunk with methanol and dried to obtain 150 g of Fmoc-Tyr(tBu)-Wang resin, and the detected substitution degree was 0.50 mmol / g.

Embodiment 2

[0049] Embodiment 2: Preparation of linaclotide precursor resin

[0050] Take by weighing the Fmoc-Tyr (tBu)-Wang resin 50g (25mmol) that the degree of substitution prepared in Example 1 is 0.50mmol / g in the solid-phase reaction column, add 50ml DMF, nitrogen bubbling swelling 60 minutes; Then use DBLK to remove Protected 2 times (50ml / time), 6min and 8min respectively, and washed 6 times with DMF (100ml / time). Weigh Fmoc-Cys(Me)-OH (48.7g, 75mmol) and HOBt (11.7g, 75mmol) and dissolve them in 100ml DMF, add DIC (13ml, 75mmol) under ice-water bath to activate for 3min, then add the mixture to the reaction column , react at room temperature for 2 hours, and detect the end of the reaction with ninhydrin (if the resin is colorless and transparent, stop the reaction; if the resin develops color, prolong the reaction for 1 hour). After the reaction is over, wash the resin 3 times with DMF (100ml / time), add DBLK for deprotection 2 times (100ml / time), 6min and 8min respectively, was...

Embodiment 3

[0052] Embodiment 3: remove protecting group Mmt

[0053] 107.6 g of the linaclotide precursor resin obtained in Example 2 was swollen with 1 liter of DMF solution for 1 hour, the solution was removed under reduced pressure, and washed twice with DCM (500 ml / time). Resin is washed with the solution 250ml of 2%TFA / DCM (v / v), each 2 minutes, until resin color changes colorless by redness, washes 2 times (500ml / time) with DCM then, DMF washes 2 times (500ml / time), the solution was sucked off under reduced pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com