Engine exhausted gas post-treatment device

An exhaust post-treatment and engine technology, applied in exhaust treatment, exhaust devices, engine components, etc., to achieve standardized design, reduce the risk of crystallization, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

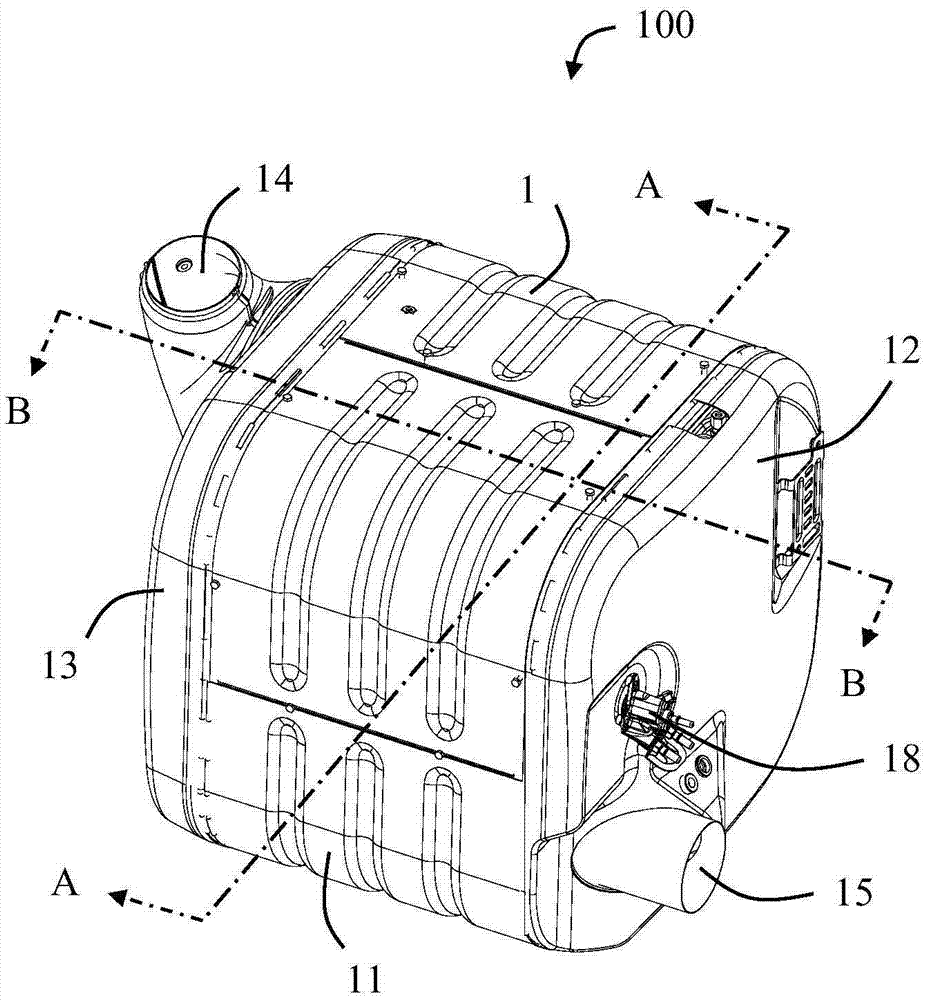

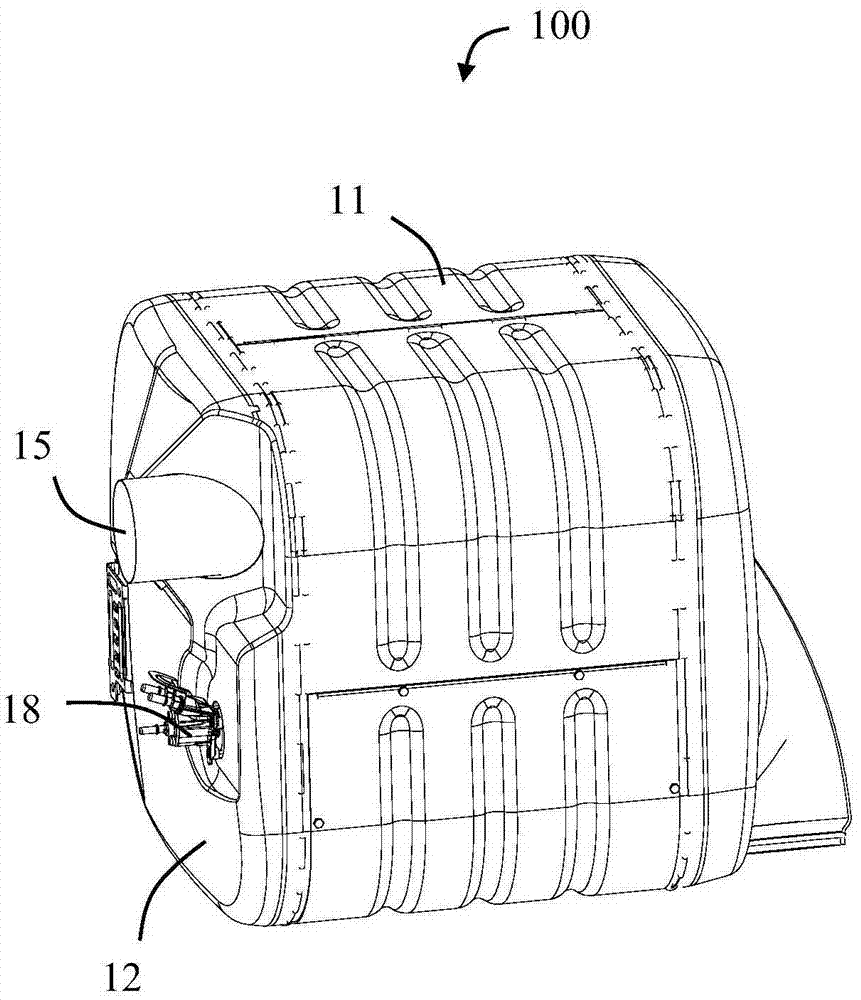

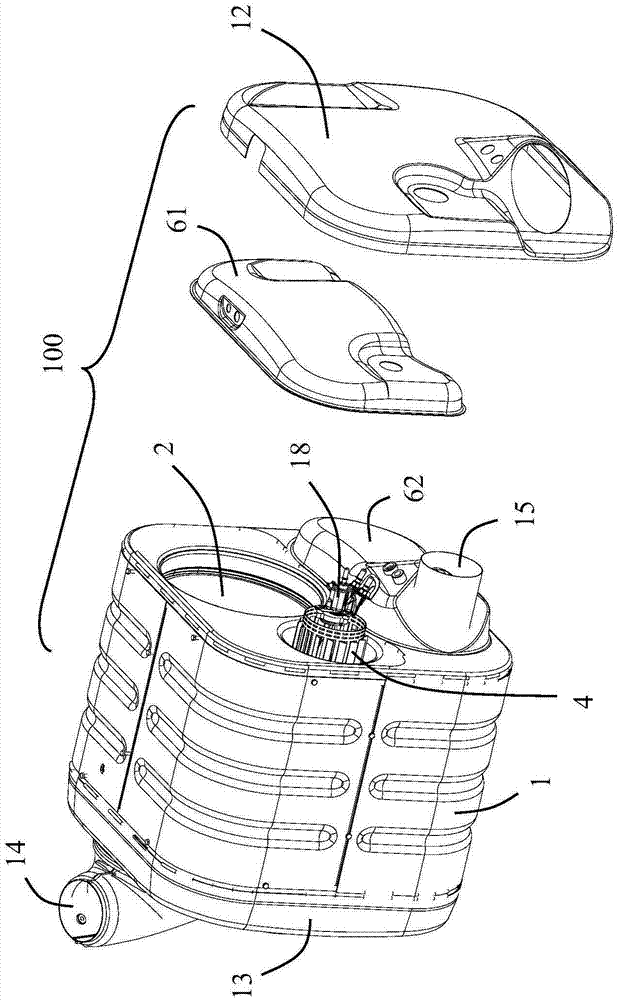

[0028] Please refer to figure 1 and figure 2 As shown, the present invention discloses an engine exhaust aftertreatment device 100, which includes an upstream aftertreatment assembly 2 with a casing 1 located in the casing 1, and a downstream aftertreatment assembly connected in series with the upstream aftertreatment assembly 2 3. And a mixing pipe 4 for connecting the upstream and downstream aftertreatment components 2 and 3 in series.

[0029] In the illustrated embodiment of the present invention, the upstream aftertreatment component 2 includes an oxidation catalytic converter (DOC) 21 and / or a particulate filter (DPF) 22, wherein the oxidation catalytic converter 21 is located at upstream of the particulate trap 22 to provide a suitable temperature when the particulate trap 22 is regenerated.

[0030] The downstream aftertreatment component 3 includes a selective catalytic reductant (SCR). In the illustrated embodiment of the present invention, the selective catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com