Containment pressure suppression and cooling system having inherent safety

A cooling system and inherently safe technology, applied in the field of containment depressurization cooling system, can solve the problems of loss of scale economy, complex system design, system failure, etc., and achieve the effect of ensuring integrity, simple and reliable system, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

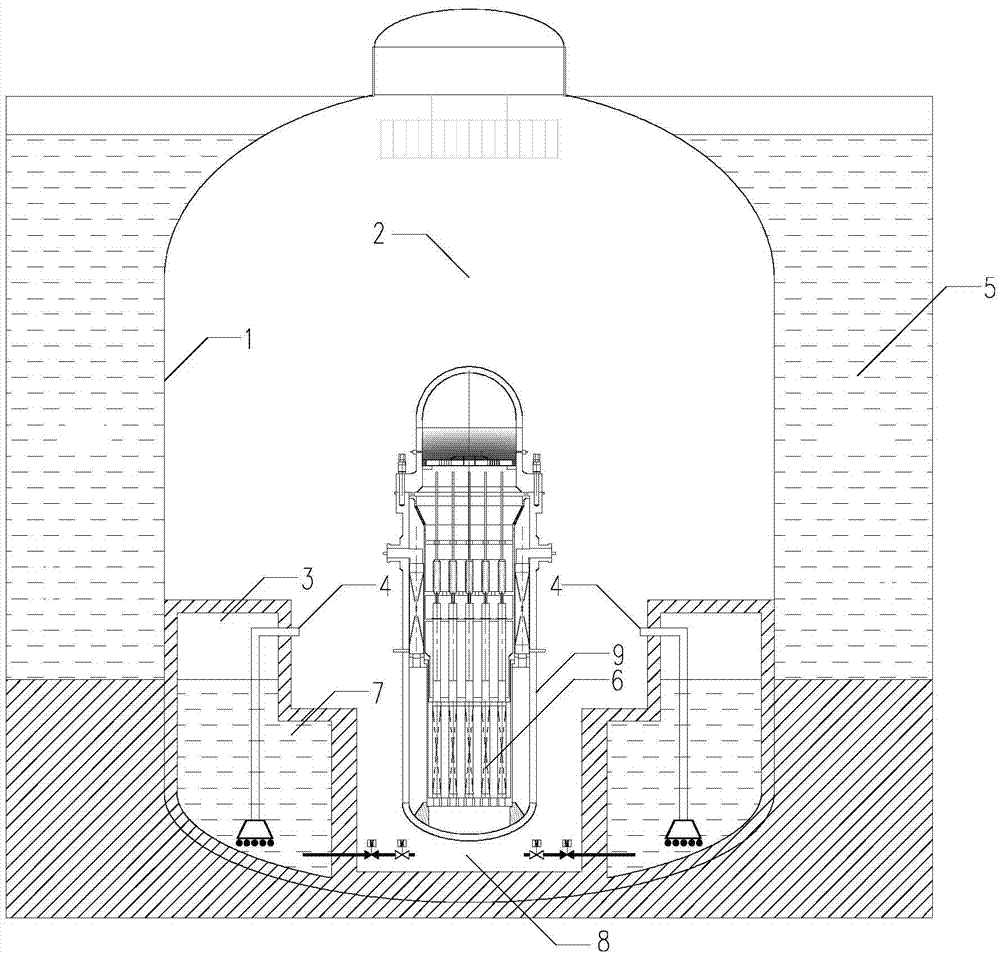

[0012] Such as figure 1 As shown, it is suitable for an integrated modular reactor with a thermal power of 200-1000 MW. The inherently safe containment depressurization cooling system of the present invention includes a steel containment 1, a dry well 2, a wet well 3, a connecting pipe 4, Shielded pool 5, the water capacity of shielded pool 5 is about 3000m 3 , no operator intervention is required 7 days after the design basis accident. The long-term cooling of the containment can be realized after the shielding pool 5 is supplemented with water.

[0013] The reactor pressure vessel 9 is located in the steel containment vessel 1 and the reactor 6 is located in the reactor pressure vessel 9 . The lower part of the reactor pressure vessel 9 (including the lower head and the core section barrel) is arranged in the circular reactor cavity 8 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com