Preparation method and application of a high-pressure resistant external expansion spiral bellows enhanced heat transfer element

A spiral corrugated tube, heat transfer enhancement technology, applied in the direction of tubular elements, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of reducing the flow area in the tube, increase heat and mass exchange, reduce flow resistance, wall thickness distribution Even curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

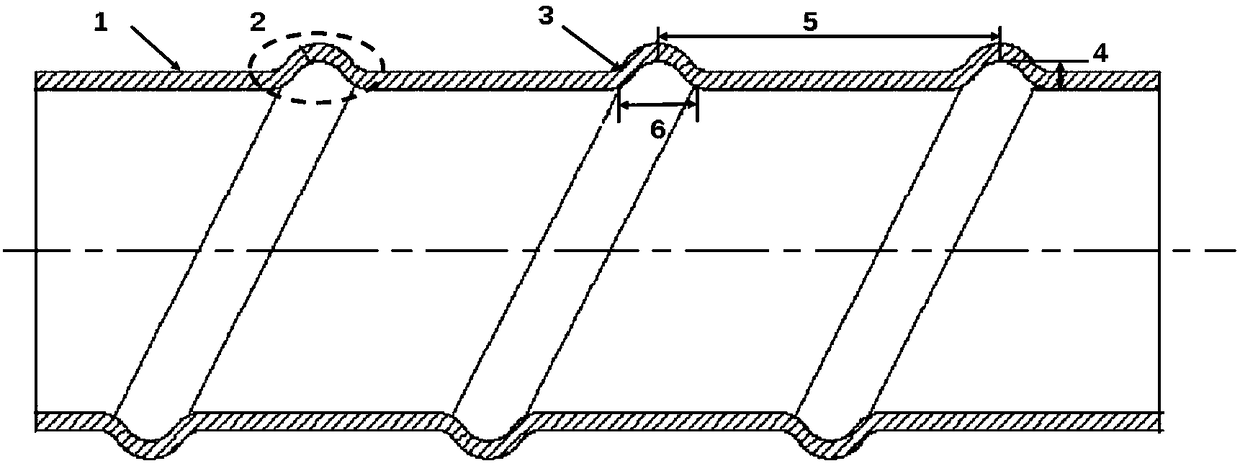

[0025] Specific implementation mode 1: This implementation mode is a preparation method of a high-pressure-resistant external expansion spiral bellows enhanced heat transfer element, which is completed according to the following steps:

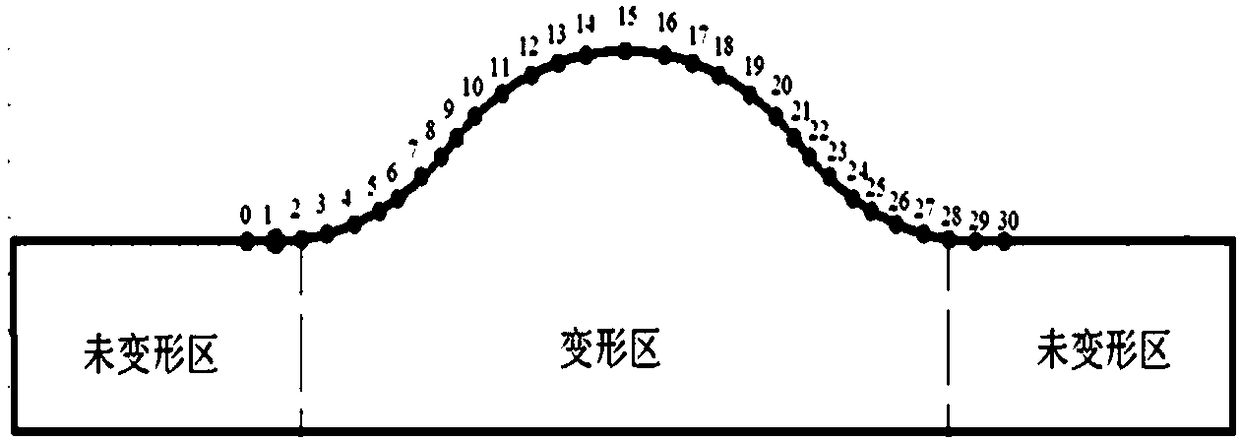

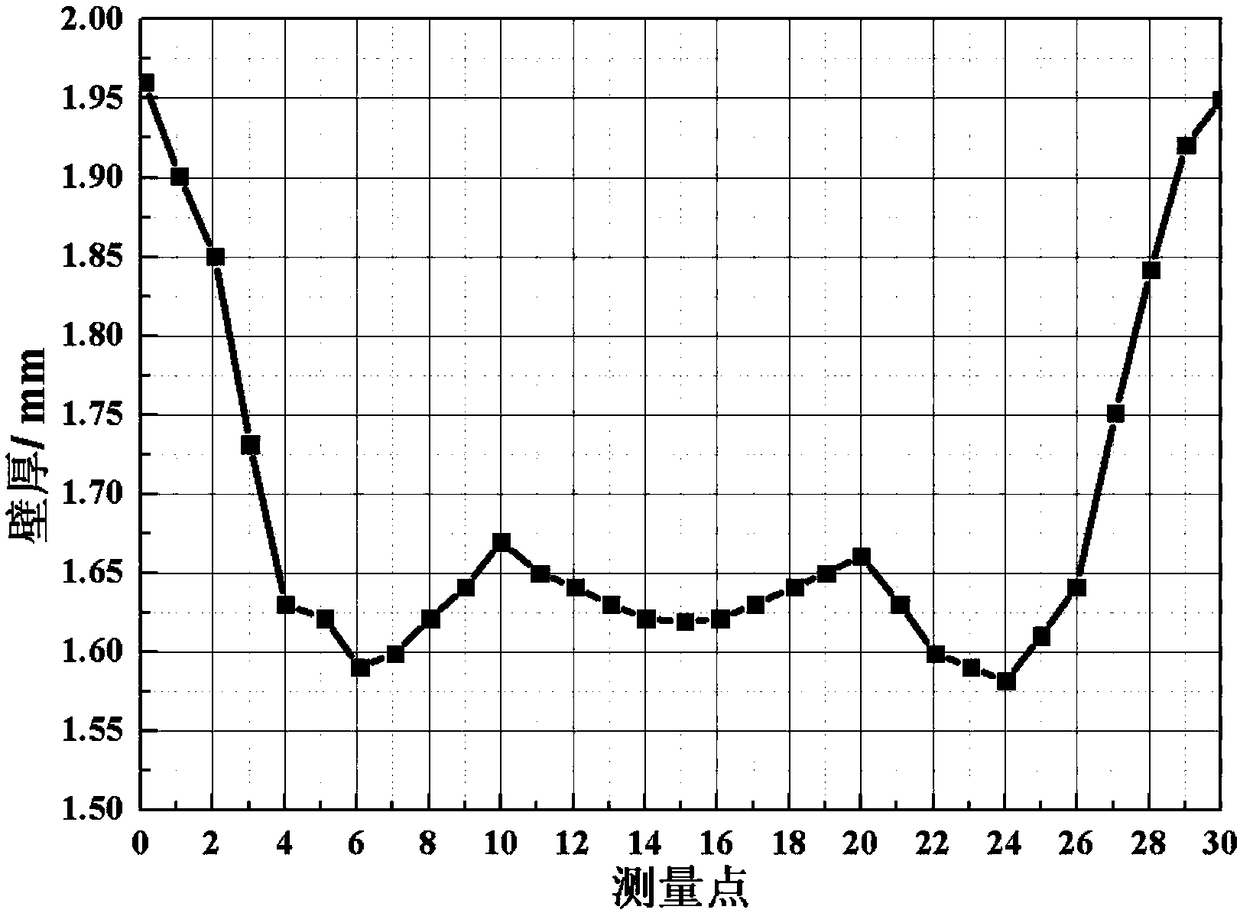

[0026] The thick-walled light tube is hydraulically expanded in the mold, and the hydraulic expansion time is 45s, that is, the high-pressure external expansion spiral corrugated tube strengthens the heat transfer element; the mold clamping force increases step by step with time during the hydraulic expansion process. , let the time be t, the unit is s, the clamping force is F, the unit is kN, when 0≤t<10s, F=450t; when 10≤t<40s, F=500t / 3+8500 / 3; When 40≤t≤45s, F=9500; in the process of hydraulic expansion, the internal pressure increases step by step with time, let the time be T, the unit is s, the internal pressure is P, the unit is MPa, when 0≤T<10s , P=12T; when 10≤T<40s, P=6T+60; when 40≤T≤45s, P=300;

[0027] The enhanced heat transfer ...

specific Embodiment approach 2

[0029] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the wall thickness of the thick-walled light pipe is 2mm, and the inner diameter of the pipe is 20mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the thick-walled light pipe is 304 stainless steel. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com