Non-circular curved surface part self-adaption polishing machine

A technology for curved surface parts and grinding machines, which is applied in the directions of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems that the machining accuracy of CNC machine tools is not easy to guarantee, the grinding process is complicated, and the machining accuracy is not high. Easy to hold, simple structure and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

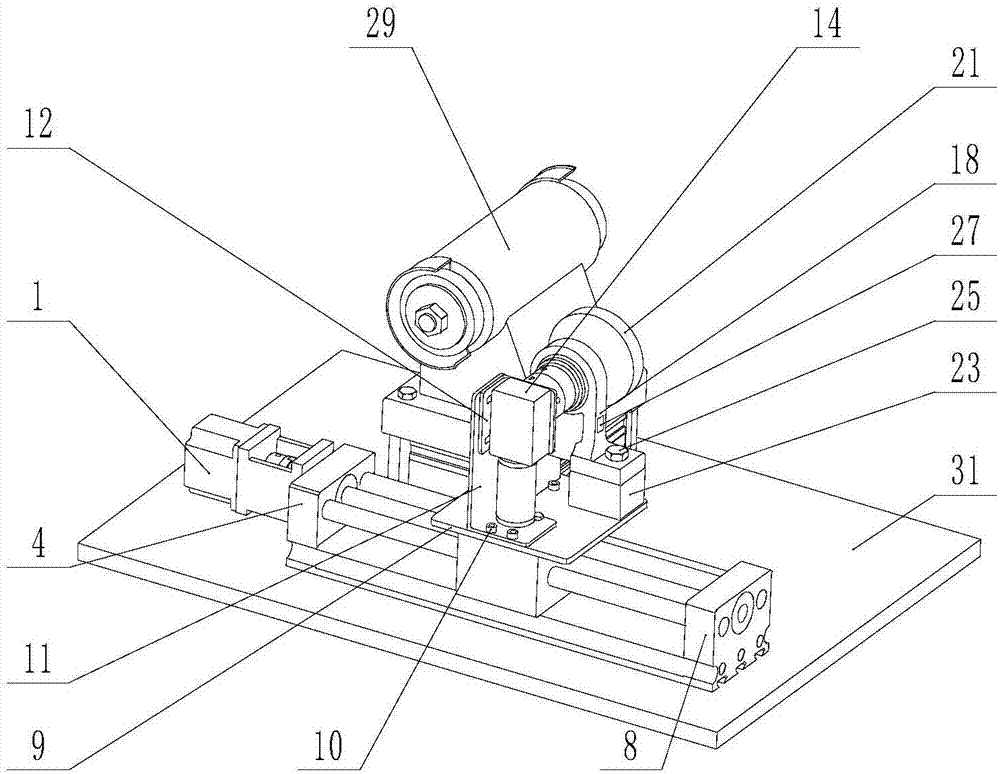

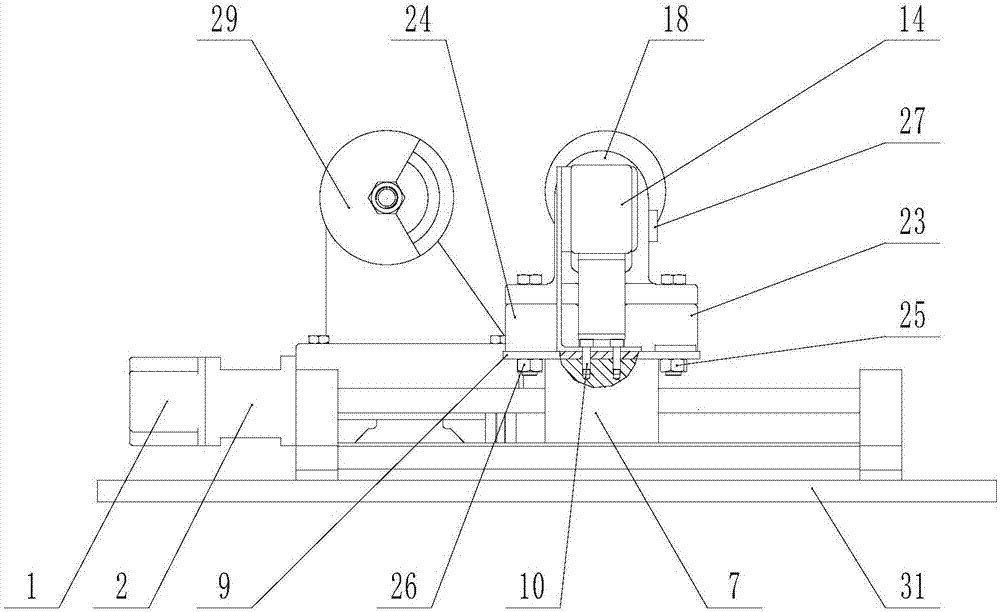

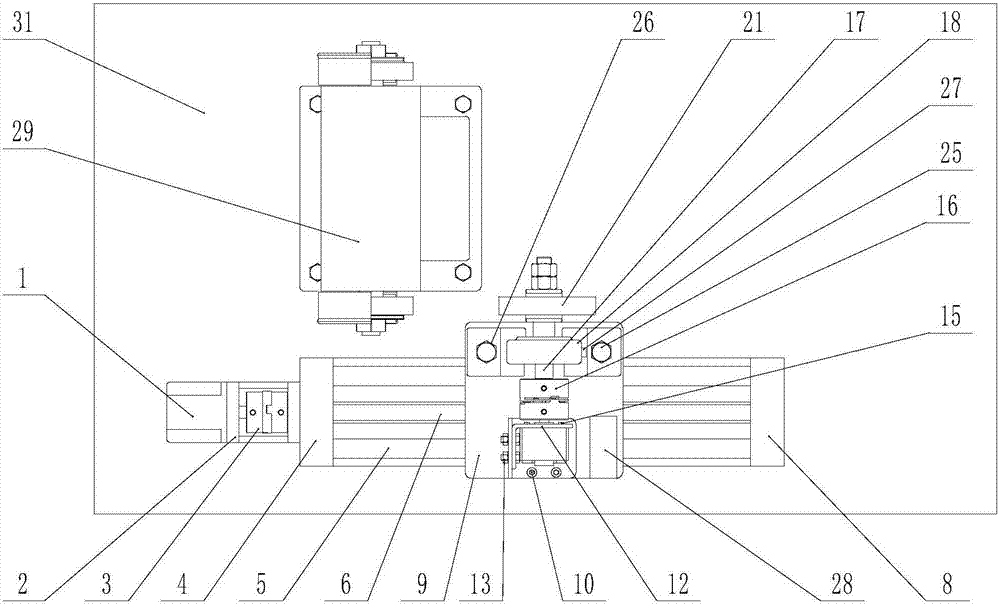

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] The self-adaptive grinding machine for non-circular curved surface parts of the embodiment of the present invention, such as Figure 1~5 As shown, the stepper motor 1 is linked with the lead screw 6 through the coupling A3, the coupling A3 is placed in the coupling support seat 2, and the lead screw 6 is set at both ends of the lead screw-guide rod with the same structure. The bearing support in the supporting seat A4 and the leading screw-guiding rod supporting seat B8, the leading screw-guiding rod supporting seat A and the leading screw-guiding rod supporting seat B are fixed on the base 31, and the leading screw is provided with a rectangular slide table 7 , there are three through holes on the rectangular sliding table, the middle hole is a threaded hole, and the movement of the rectangular sliding table can be realized by cooperating with the lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com