Inertia wheel and manufacturing method thereof

A production method and inertia wheel technology, applied in the field of inertia wheels, can solve the problems of metal dust pollution, high material cost, difficulty in making inertia wheel cast iron, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

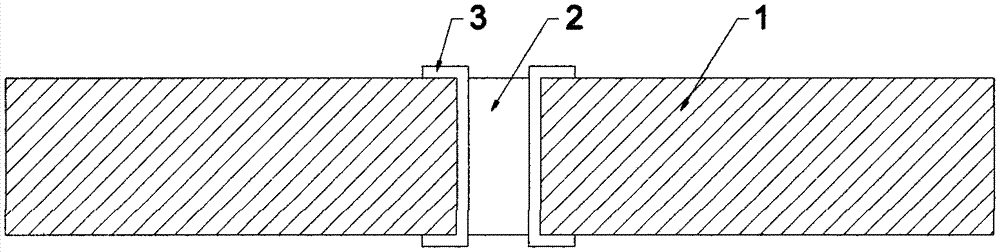

[0014] Such as figure 1 Shown, a kind of inertial wheel, its inertial wheel body 1 is integrally formed by glass fiber reinforced plastics.

[0015] Wherein the central axis hole 2 of the inertia wheel body 1 is provided with a metal insert 3 connected with the inertia wheel body, and the metal insert 3 is integrally formed with the inertia wheel body 1 .

[0016] In addition, the components and mass percentages of the raw materials for making the inertia wheel are: 10%-30% of epoxy resin and phenolic resin, 5%-75% of iron powder, 5%-55% of calcium carbonate powder or quartz powder, curing agent 0.5%-5%, reinforced glass fiber 5%-10%, stabilizer 2%-8%, plasticizer 3%-7%; the above raw materials are stirred evenly by a stirring mechanism,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com