Synthetic method for p-methyl phenyl serine ethyl ester

A technology of thiamphenylphenylserine ethyl ester and thiamphenylphenylserine copper, which is applied in the field of synthesis of florfenicol intermediates, can solve the problems of unfavorable environmental protection, disadvantages, and a large amount of waste acid, so as to protect the environment and improve Esterification conversion rate and the effect of reducing the amount of waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

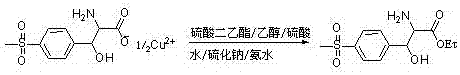

[0022] The present invention relates to a kind of synthetic method of ethyl sulfonyl phenyl serine, comprising the following steps:

[0023] Reaction 1 (new), add diethyl sulfate, ethanol (1eq), sulfuric acid (1eq) and p-thymphenylphenylserine copper salt (1eq) into the reaction kettle, and react under reflux for 5-9 hours, and monitor the esterification by HPLC When the conversion rate is greater than 95% to 99%, the reaction ends. Insulated pressure filtration, the filter cake is washed with a small amount of ethanol, and the filter cake is copper sulfate (recovered for later use). Cool the mother liquor to crystallize, drop to -5~0°C for suction filtration, recover the mother liquor for further use; the filter cake is p-thiamphenylphenylserine ethyl sulfate, and then dissolve in water, remove copper with sodium sulfide, and obtain p-methylsulfone through ammonia ammonia analysis phenylserine ethyl ester.

[0024] Reaction 2 (applied mechanically), add recovered mother liq...

Embodiment 1

[0032] 1) Add 200g of diethyl sulfate, 20g of ethanol, 34g of sulfuric acid and 100g of p-thymphenylphenylserine copper salt into a 1000mL reactor, stir at room temperature for 1h, heat and reflux for 5-9h, and monitor the conversion rate of esterification by HPLC. 95% to 99% of the reaction is over. Insulated pressure filtration, the filter cake was washed with a small amount of 30g of hot ethanol, and the filter cake was copper sulfate (recovered for later use). Cool the mother liquor to crystallize, drop to -5 ~ 0 ℃ for suction filtration, and recover the mother liquor for use; Add ammonia water dropwise at 5°C to adjust the pH to 8.0; filter with suction and dry to obtain 93 g (about 94%) of p-thymphenylphenylserine ethyl ester as a white solid.

[0033] 2) Add 300g of recovered mother liquor, 24g of ethanol, 35g of sulfuric acid and 100g of p-thymphenylphenylserine copper salt into the reaction kettle, stir at room temperature for 1h, heat and reflux for 5-9h, and monito...

Embodiment 2

[0035] 1) Add 250g of diethyl sulfate, 24g of ethanol, 45g of sulfuric acid and 100g of p-thymphenylphenylserine copper salt into a 1000mL reactor, stir at room temperature for 1h, heat and reflux for 5-9h, and monitor the conversion rate of esterification by HPLC. 95% to 99% of the reaction is over. Insulated pressure filtration, the filter cake was washed with a small amount of 30g of hot ethanol, and the filter cake was copper sulfate (recovered for later use). Cool the mother liquor to crystallize, drop to -5 ~ 0 ℃ for suction filtration, and recover the mother liquor for use; Add ammonia water dropwise at 5°C to adjust the pH to 8.0; filter with suction and dry to obtain 91 g (about 92%) of p-thymphenylphenylserine ethyl ester as a white solid.

[0036] 2) Add 300g of recovered mother liquor, 27g of ethanol, 48g of sulfuric acid and 100g of p-thymphenylphenylserine copper salt into the reaction kettle, stir at room temperature for 1h, heat and reflux for 5~9h, and monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com