Aluminium-based lead silver alloy composite anode plate and preparation method thereof

A lead-silver alloy, composite anode technology, applied in electrodes, electrolytic inorganic material coating, electrolysis process, etc., to achieve the effects of easy cleaning, lower material costs, and lower cell voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

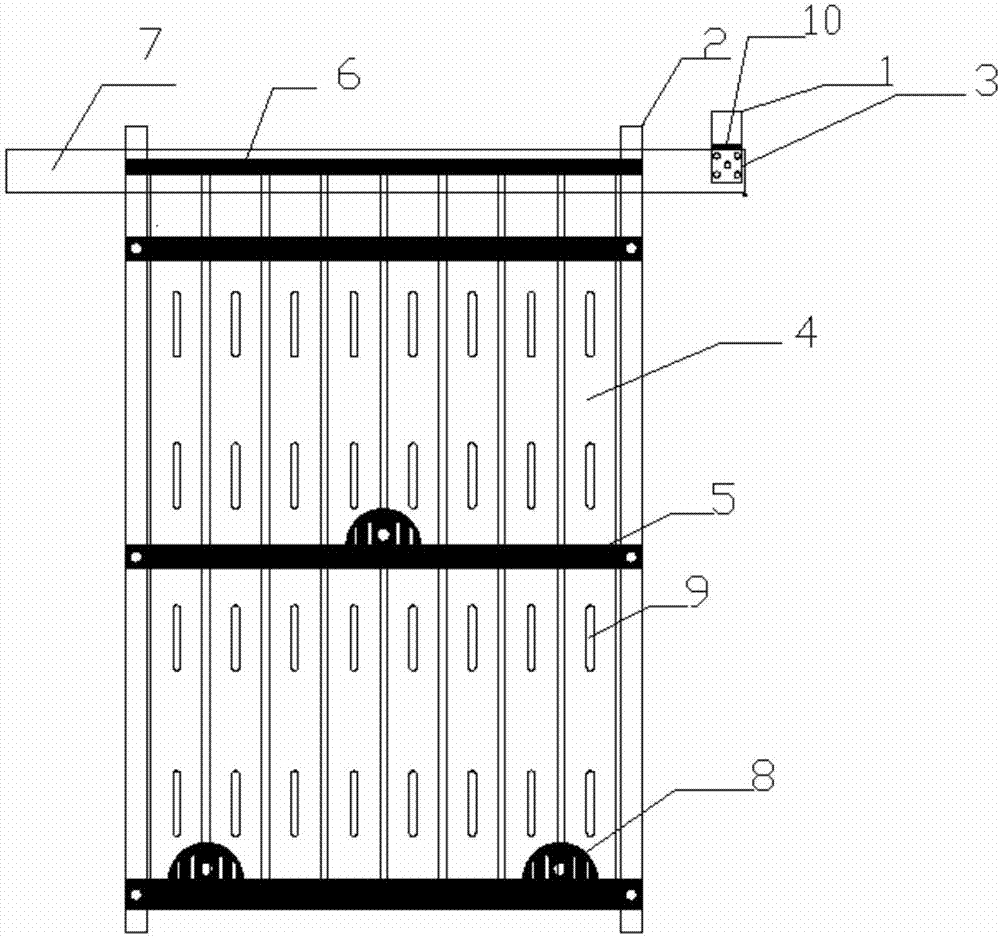

Image

Examples

Embodiment 1

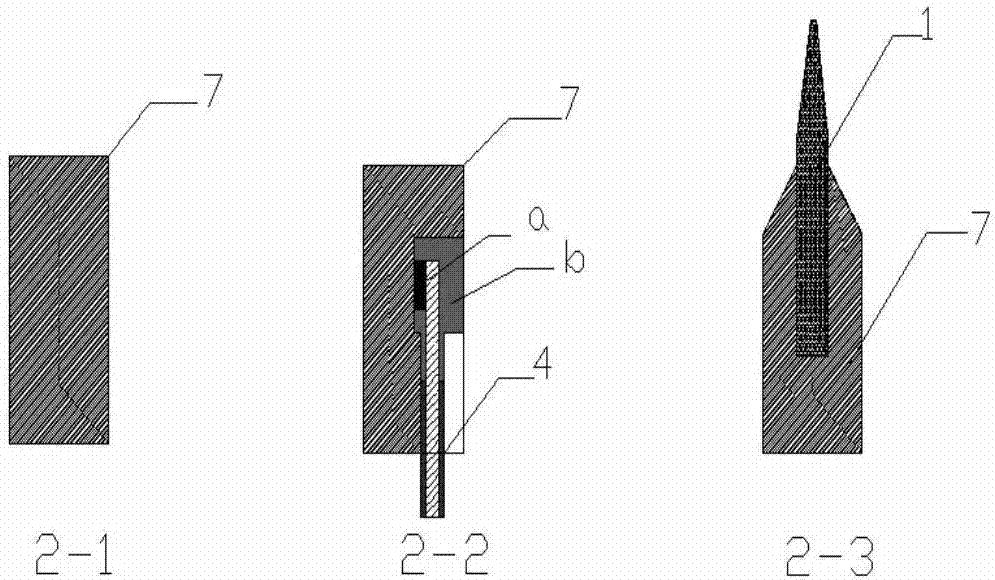

[0056] Method a: The copper-aluminum composite conductive head is produced by pressure casting, and then welded with the conductive aluminum beam by friction welding to obtain a complete copper-aluminum composite conductive beam.

[0057] Method b: The aluminum conductive beam adopts a pressure casting method, and the copper conductive head is cast on one end of the conductive beam to produce a copper-aluminum composite conductive beam.

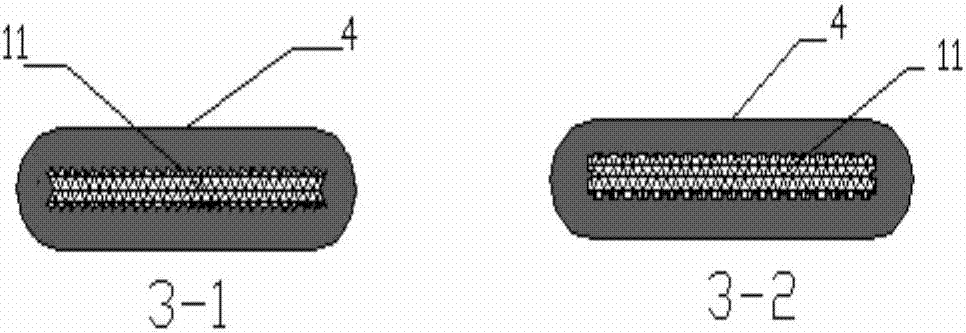

[0058] The surface of the aluminum plate with a width of 35mm and a thickness of 4mm is subjected to drawing and punching treatment, and then undergoes alkali washing, pickling, and water washing to remove the aluminum oxide film on the surface of the aluminum or aluminum alloy plate. Or use a plate surface cleaner to scrape off the aluminum oxide film on the plate surface to enhance the surface conductivity of the aluminum plate, thereby improving the electrical efficiency of the anode plate.

[0059] The lead-silver alloy is pressed on the ...

Embodiment 2

[0067] The production process of the conductive beam: the aluminum conductive beam adopts the pressure casting method, and the copper conductive head is cast on one end of the conductive beam to produce a copper-aluminum composite conductive beam.

[0068] The surface of the aluminum plate with a width of 15, 20, 35, 40, 50, and 70 mm and a thickness of 4 mm is subjected to drawing and punching treatment, and then undergoes alkali washing, pickling, and water washing to remove three-dimensional stains on the surface of the aluminum or aluminum alloy plate. Aluminum oxide film, or use a plate surface cleaner to scrape off the aluminum oxide film on the surface of the plate, so that the surface conductivity of the aluminum plate can be enhanced, thereby improving the electrical efficiency of the anode plate.

[0069] The lead-silver alloy is pressed on the surface of the aluminum or aluminum alloy plate that has been drawn and punched by the pressing process to obtain the lead-si...

Embodiment 3

[0076] The production process of the conductive beam: the aluminum conductive beam adopts the pressure casting method, and the copper conductive head is cast on one end of the conductive beam to produce a copper-aluminum composite conductive beam.

[0077] Carry out drawing and punching treatment on the surface of the aluminum plate with a width of 35mm and a thickness of 4mm, and then undergo alkali washing, pickling, and water washing to remove the aluminum oxide film on the surface of the aluminum or aluminum alloy plate, or scrape off the plate with a plate surface cleaner The aluminum oxide film on the surface enhances the surface conductivity of the aluminum plate, thereby improving the electric efficiency of the anode plate.

[0078] The lead-silver alloy is pressed on the surface of the aluminum or aluminum alloy plate that has been drawn and punched by the pressing process to obtain the lead-silver alloy composite anode plate body of aluminum or aluminum alloy, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com