Device for recycling waste heat of engine exhaust pipe so as to improve comprehensive oil consumption utilization rate of engine

An engine and exhaust pipe technology, which is applied to exhaust devices, engine components, combustion engines, etc., can solve the problems of large temperature changes in thermoelectric power generation voltage, decreased combustion efficiency of ethanol gasoline, and poor atomization of fuel injectors. The effect of prolonging the service life, solving the short storage period and improving the comprehensive thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

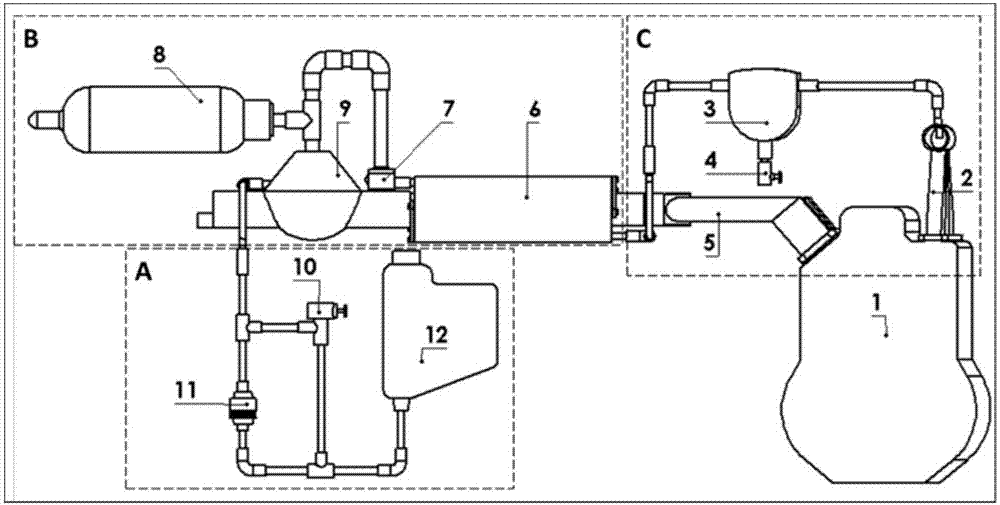

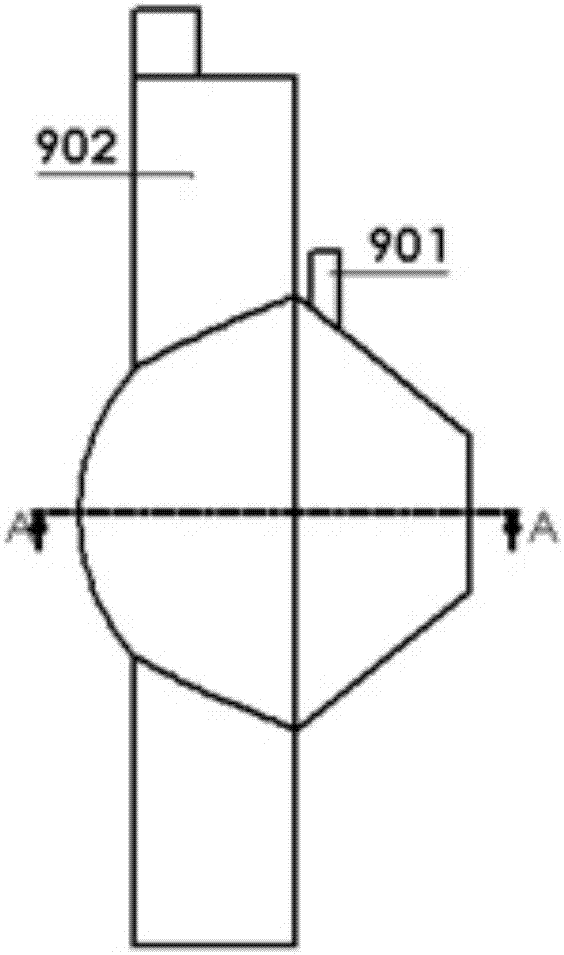

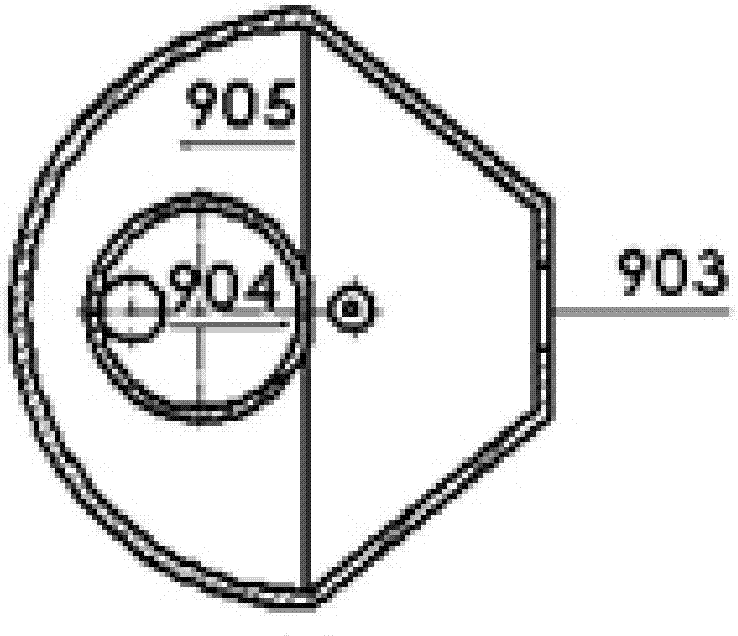

[0035] figure 1 Shown is an embodiment of the device for recovering engine exhaust pipe waste heat of the present invention to improve the comprehensive fuel consumption utilization rate of the engine. In the existing automobile technology, after the automobile engine 1 works normally and stably, the temperature of the exhaust manifold 5 is at 600 ℃ or more, and the temperature of the evaporator 9 with the three-way catalytic converter of the present invention is more than 300 ℃. The device uses the waste heat of engine exhaust gas to dehydrate ethanol to prepare ethylene, and then participates in the combustion system with ethylene. The device for recovering waste heat from the exhaust pipe of the engine to improve the utilization rate of the comprehensive fue...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap