Distributor internally provided with jet flow hole plate

A technology of jet holes and distributors, which is used in fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve the problems of refrigerant bias flow, large liquid hammer noise in distributors, poor heat exchange efficiency, etc., and achieves fatigue resistance and durability. The effect of improved corrosion performance, material and processing cost savings, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

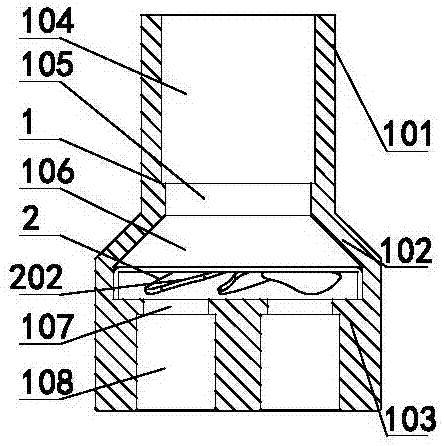

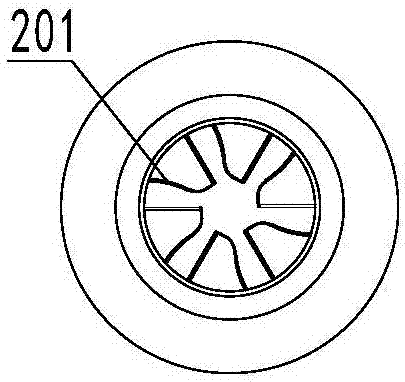

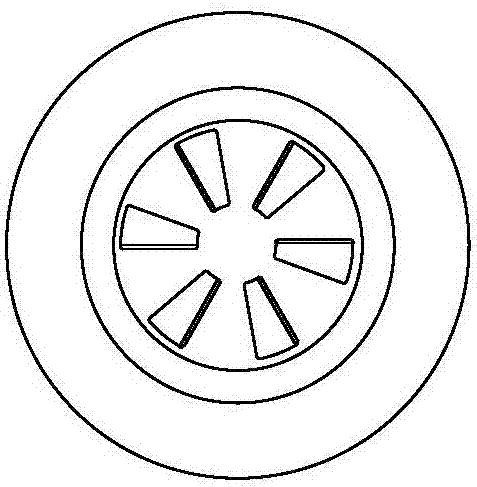

[0032] Such as Figure 1-4 As shown, the present invention is a distributor with a built-in jet orifice.

[0033] The dispenser described in this embodiment includes a main body 1, and the material of the main body 1 is preferably copper or aluminum. The main body 1 has an inlet end 101 and a plurality of outlet ends 103 . The middle part of the main body 1 is transitioned by a tapered transition section 102 to enlarge the inner cavity, and the diameter of the outlet end 103 is larger than that of the inlet end 101 .

[0034] The main body 1 also includes a mixing chamber 106, and a jet orifice 2 is arranged below the mixing chamber 106. The jet orifice 2 should be put into the mixing chamber of the main body 1 before the tapered transition section 102 is formed by spinning or other processes. Inside 106 , the main body 1 undergoes spinning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com