Metal plate defect location method based on laser Lamb wave frequency-wave number analysis

A wave frequency, metal plate technology, applied in the field of metal plate defect positioning, can solve the problems of inability to realize multi-frequency defect imaging and single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Provide following experimental examples in conjunction with the content of the inventive method:

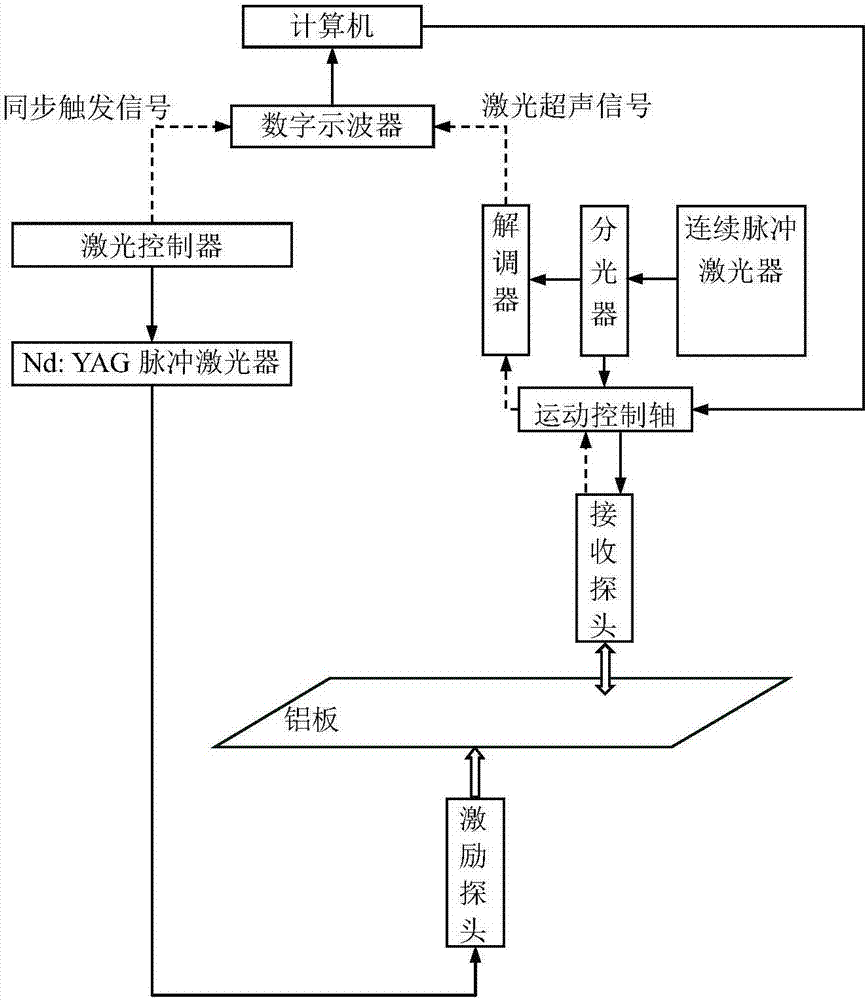

[0041] figure 1It is a laser ultrasonic detection system, which is divided into two parts: excitation and reception. The laser ultrasonic excitation part includes a laser controller, a pulse laser, and a laser excitation probe. The laser controller provides energy to the pulsed laser to excite the pulsed laser to generate pulsed laser, which is then emitted by the laser excitation probe. At the same time, the laser controller provides a synchronous trigger signal to the oscilloscope to realize the synchronous excitation and acquisition of laser ultrasonic signals. The laser ultrasonic receiving system includes a continuous pulse laser, a beam splitter, a demodulator, and a laser receiving probe. The continuous pulse laser outputs continuous laser light, which is divided into two beams after passing through the beam splitter. One beam is directly input to the demodulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com