Method for preparing core-shell type barium titanate/polyaniline composite wave-absorbing material

A composite wave-absorbing material, barium titanate technology, applied in the field of wave-absorbing materials, can solve the problems of unstudied BaTiO3/PANI composite material wave-absorbing performance, large particle size, etc., to improve broadband wave-absorbing performance and broaden the application field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Nano-BaTiO 3 preparation of

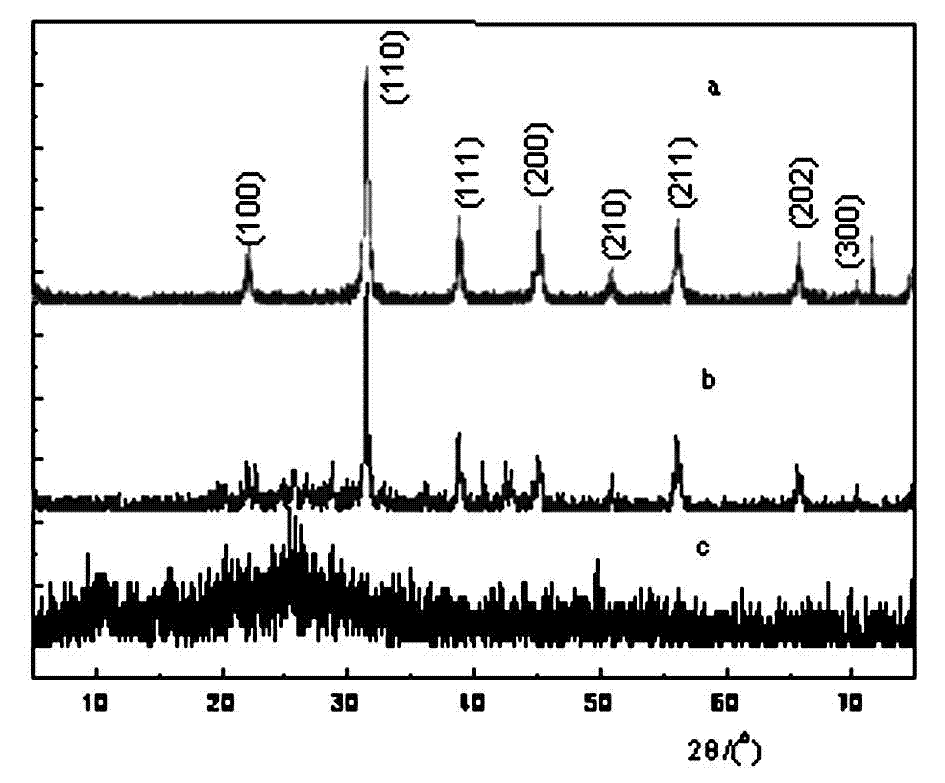

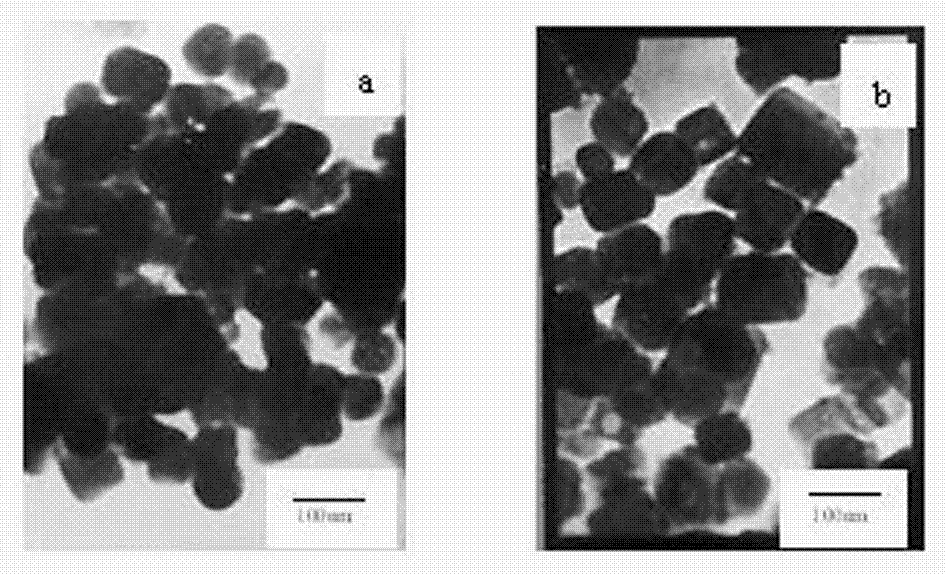

[0031] Weigh 2.13g barium acetate (Ba(CH 3 COO) 2 ) was dissolved in 7ml of distilled water at 50°C, and after it was completely dissolved, it was cooled to room temperature to obtain liquid A; 2.87g of tetrabutyl titanate (C 16 h 36 o 4 Ti) was dissolved in 5ml of absolute ethanol, stirred on a magnetic stirrer for 30min, and mixed evenly to obtain liquid B; add 3ml of glacial acetic acid dropwise to liquid B, then add liquid A dropwise, and place at 40 °C on a magnetic stirrer, stirring for 1 h to form a gel. After the gel was aged at room temperature for 3 hours, it was dried in a constant temperature dryer at 80° C. to obtain a dry gel. Finally, the xerogel was calcined in a muffle furnace at 800 °C for 2 h to obtain BaTiO 3 Powder, its XRD sees figure 1 a, TEM see figure 2 a.

[0032] 2. Barium titanate / polyaniline (BaTiO 3 / PANI) composites

[0033] Take 5g BaTiO 3 Disperse in 5mL distilled water, add 0.25g KH560 1%...

Embodiment 2

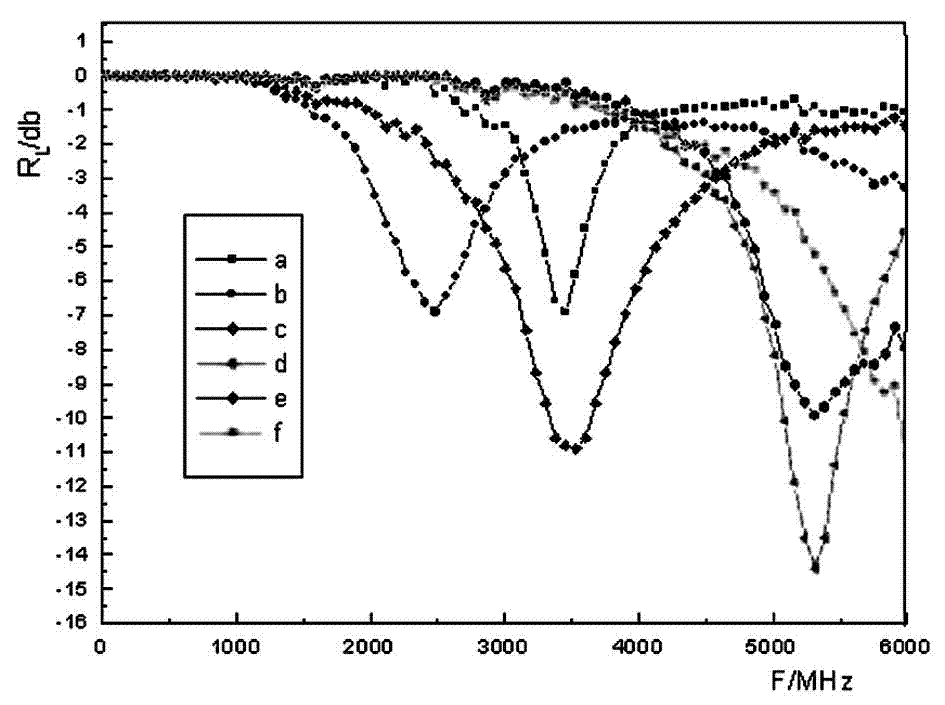

[0037] Take 12.3g BaTiO 3 Disperse in 5mL distilled water, add 1% coupling agent alcohol aqueous solution prepared with 0.24g KH570 at one time, after stirring for 40min, slowly add 12ml aniline hydrochloric acid solution dropwise (6ml aniline is dissolved in 6ml 1.5mol / L hydrochloric acid) After the dropwise addition, place in an ice-water bath, stir for 40 minutes, cool the reaction temperature to about 0°C, and dropwise add ammonium persulfate hydrochloric acid solution (15.08g ammonium persulfate dissolved in 24ml 1.5mol / L hydrochloric acid), after reacting for 7 hours, filter with suction, wash 3 times with 1.5mol / L hydrochloric acid, wash with a large amount of distilled water until the filtrate pH=6, dry at 70°C for 24 hours, and grind to obtain BaTiO 3 / PANI Composite. Its absorption curve is shown in image 3 c.

Embodiment 3

[0039] Take 12.3g BaTiO 3 Disperse in 7.5mL distilled water, add 1% coupling agent alcohol aqueous solution prepared with 0.21g KH560 at one time, after stirring for 40min, slowly add 6ml aniline hydrochloric acid solution dropwise (3ml aniline dissolved in 3ml 1.3mol / L hydrochloric acid ), after the dropwise addition, place in an ice-water bath, stir for 40 minutes, cool the reaction temperature to about 0°C, and add ammonium persulfate hydrochloric acid solution dropwise at a rate of 10 s / drop (7.54g ammonium persulfate dissolved in 12ml 1.3mol / L hydrochloric acid), after reacting for 7 hours, filter with suction, wash 3 times with 1.3mol / L hydrochloric acid, wash with a large amount of distilled water until the filtrate pH=6, dry at 80°C for 24 hours, and grind to obtain BaTiO 3 / PANI Composite. Its XRD see figure 1 b, TEM see figure 2 b, the absorption curve see image 3 d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com