A kind of hyperbranched damping agent and its preparation method and application

A damping agent and damping rubber technology, applied in the field of damping materials, can solve the problems of unsuitability for large-scale production, high processing cost, low application value, etc., and achieve the effects of easy to achieve large-scale scale, simple preparation process, and improved damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

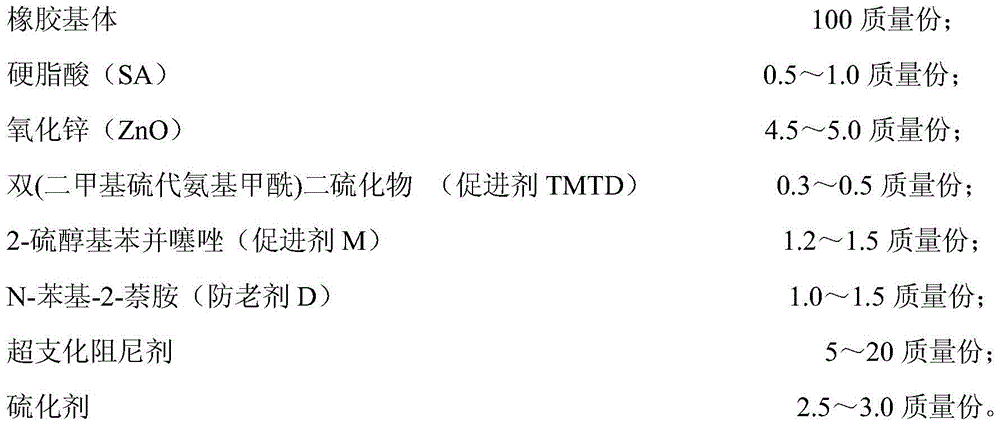

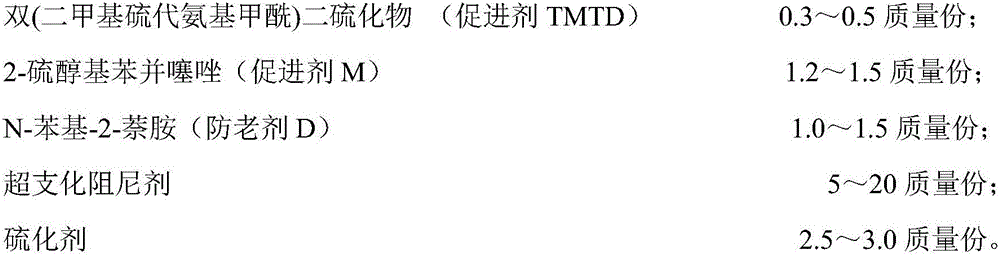

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of silane quaternary ammonium salt: Mix 20mL of 3-chloropropylmethyl diethoxysilane with 100mL of absolute ethanol, add it to a dry three-necked flask, and then add 5mL of decyldimethyl tertiary amine , 15mL cetyl / octadecyl dimethyl tertiary amine and 0.10g sodium iodide; under nitrogen protection, stir and reflux for 14-42 hours; cool to room temperature, remove sodium iodide by suction filtration, and then carry out vacuum distillation After removing the solvent, a light yellow viscous liquid is obtained: silane quaternary ammonium salt.

[0041] 2. Preparation of silane-modified organomontmorillonite: mix 20g of inorganic montmorillonite with 40mL of silane quaternary ammonium salt, add 100mL of 30% ethanol aqueous solution, stir and react at 60°C for 3 hours; filter, collect The solid was washed and dried in vacuum at 70°C to obtain silane-modified organomontmorillonite.

[0042] 3. Preparation of AB2-type monomer: Dissolve 72g of diisopropanolamine ...

Embodiment 2

[0054] 1. Preparation of silane quaternary ammonium salt: Mix 25mL of 3-chloropropylmethyl diethoxysilane with 100mL of absolute ethanol, add it to a dry three-necked flask, and then add 5mL of decyldimethyl tertiary amine , 30mL cetyl / octadecyl dimethyl tertiary amine and 0.15g sodium iodide; under nitrogen protection, stir and reflux for 14-42 hours; cool to room temperature, remove sodium iodide by suction filtration, and then carry out vacuum distillation After removing the solvent, a light yellow viscous liquid is obtained: silane quaternary ammonium salt.

[0055] 2. Preparation of silane-modified organomontmorillonite: mix 40g of inorganic montmorillonite with 50mL of silane quaternary ammonium salt, add 100mL of 30% ethanol aqueous solution, stir and react at 60°C for 3 hours; filter, collect The solid was washed and dried in vacuum at 70°C to obtain silane-modified organomontmorillonite.

[0056] 3. Preparation of AB2-type monomer: Dissolve 75g of diisopropanolamine ...

Embodiment 3

[0069] 1. Preparation of silane quaternary ammonium salt: mix 30mL 3-chloropropylmethyl diethoxysilane with 100mL absolute ethanol, add it to a dry three-necked flask, and then add 5mL decyldimethyl tertiary amine , 30mL cetyl / octadecyl dimethyl tertiary amine and 0.15g sodium iodide; under nitrogen protection, stir and reflux for 14-42 hours; cool to room temperature, remove sodium iodide by suction filtration, and then carry out vacuum distillation After removing the solvent, a light yellow viscous liquid is obtained: silane quaternary ammonium salt.

[0070] 2. Preparation of silane-modified organomontmorillonite: mix 60g of inorganic montmorillonite with 60mL of silane quaternary ammonium salt, add 100mL of 30% ethanol aqueous solution, stir and react at 60°C for 3 hours; filter, collect The solid was washed and dried in vacuum at 70°C to obtain silane-modified organomontmorillonite.

[0071] 3. Preparation of AB2-type monomer: Dissolve 80g of diisopropanolamine in 100mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com