Backlight assembly of liquid crystal displayer

A technology for liquid crystal displays and backlight components, which is applied to instruments, optics, nonlinear optics, etc., can solve the problems of poor flatness of reflective films and thick thickness of backlight modules, and achieves the effect of reducing thickness, good flatness, and reducing shadow phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

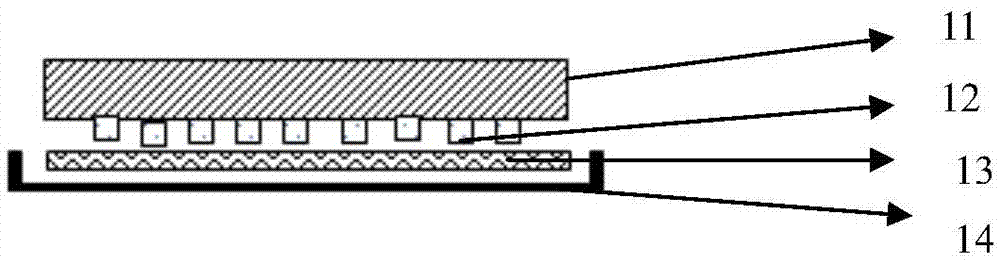

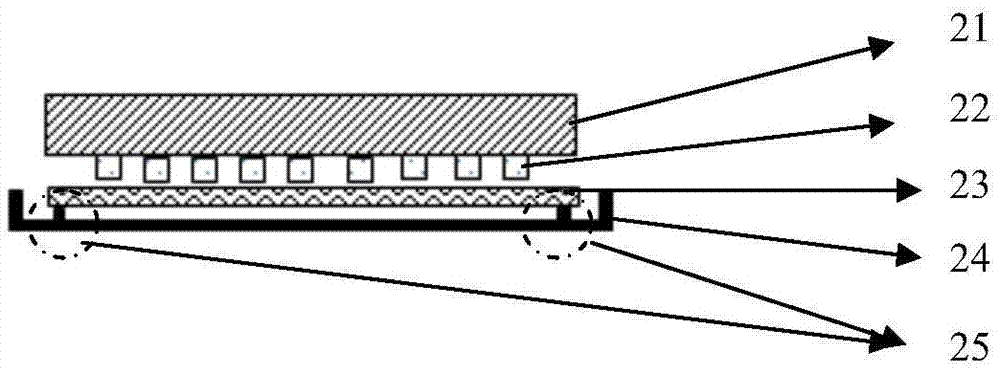

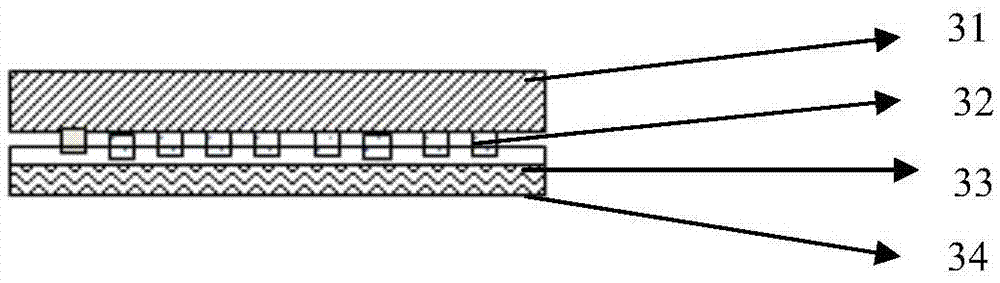

[0052] The invention provides a backlight assembly of a liquid crystal display, the backlight assembly sequentially includes a light guide plate, an adhesive layer and a reflective film; the reflective film is bonded to the light guide plate through the adhesive layer; the light guide plate One surface has dots embedded in the adhesive layer.

[0053] During the preparation process, the organic solvent ethyl ester was added to the polyurethane-modified acrylic pressure-sensitive adhesive for dilution until the solid content of the adhesive was 30%; then the adhesive was coated on the reflective film DJX 300 (Ningbo Longyang Technology Co., Ltd.) on the surface, the wet film thickness is 11.5 μm; then put the reflective film coated with glue in an 80-degree oven to dry, and evaporate the solvent; finally, paste the above-mentioned dried reflective film on the dots of the light guide plate Surface, through the laminating machine (to ensure uniform contact between the adhesive la...

Embodiment 2

[0055] The backlight assembly provided in Example 1, wherein the wet film thickness is 14 μm. The material of the light guide plate is polymethyl methacrylate (PMMA), the thickness of the light guide plate is 4 mm, and the height of dots is 8 μm.

Embodiment 3

[0057] The backlight assembly provided in Example 1, wherein the wet film thickness is 16 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com