Resin sand casting site harmful flue gas purification method using materials capable of performing online regeneration and absorption

A flue gas purification and resin sand technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low gas production, difficult to copy and use, and low concentration of organic matter, so as to ensure reliability and stability , Reduce the effect of occupational hazards and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

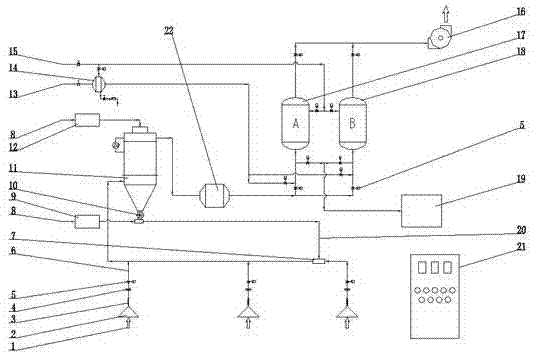

[0021] Such as figure 1 Shown is a method for purifying harmful flue gas at the site of resin sand casting that can regenerate the adsorbent on-line, comprising the following steps:

[0022] Step 1: Construct a resin sand casting on-site harmful flue gas purification treatment system that can regenerate the adsorbent on-line, which includes a system automatic control device 21 and is sequentially set at each point 1 that generates harmful flue gas at the resin sand pouring and cooling stations Harmful smoke collection hood 2 with a section of soft air duct 3 that can be adjusted arbitrarily, and each branch hard air duct 6 is equipped with manual air volume adjustment valve 4 and pipeline switching valve 5, which are harmful to the work area. Effective capture of flue gas;

[0023] The second step: set a set of powder spraying device on the hard air duct 6 of the harmful flue gas purification treatment system,

[0024] This part includes: using compressed air source 8, powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com