Flue gas purification adsorbent for saline-alkali soil improvement and saline-alkali soil improvement method

A technology for saline-alkali soil improvement and flue gas purification, which is applied in the direction of chemical instruments and methods, restoration of polluted soil, application, etc., can solve pollution and other problems, achieve the effect of increasing interaction, quick effect, and reducing soil alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

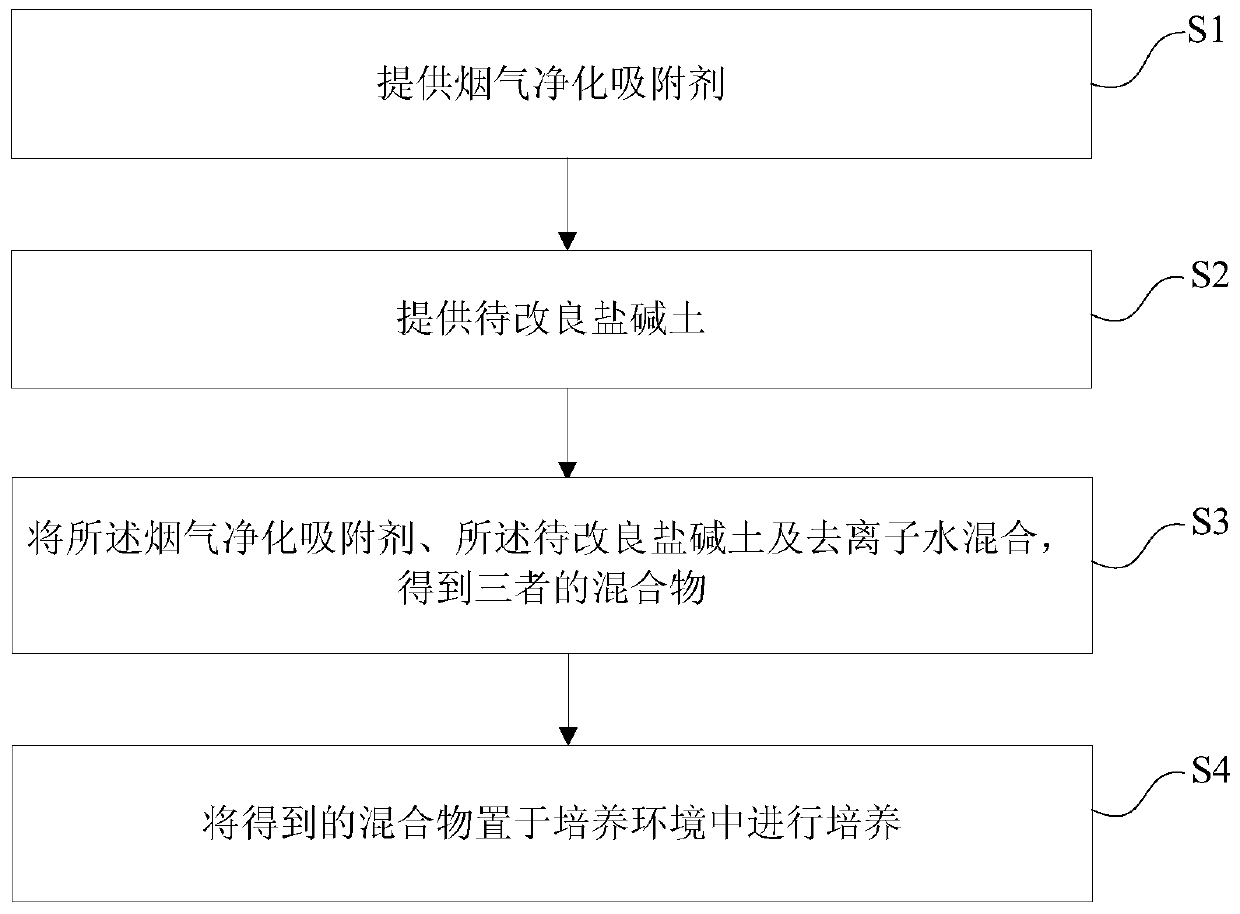

Method used

Image

Examples

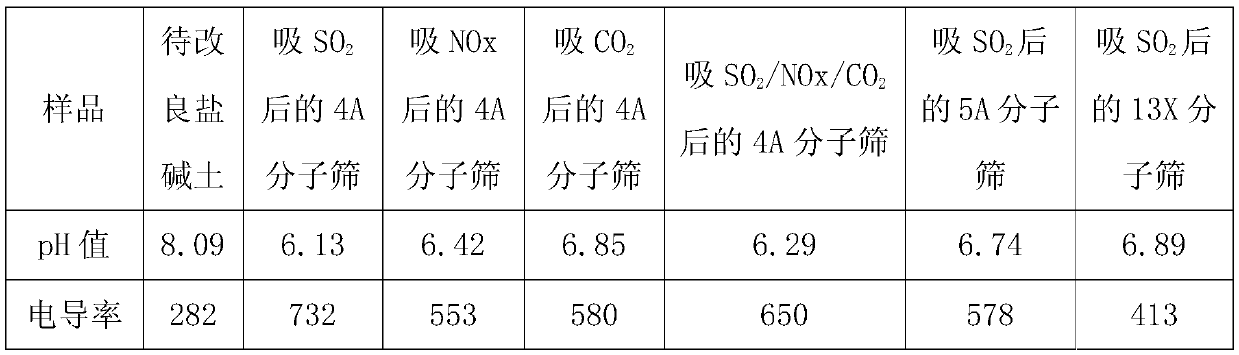

Embodiment 1

[0058] 1) Provide a certain amount of saline-alkali soil to be improved, air-dry the saline-alkali soil to be improved for several days, sieve through a 20-mesh sieve, and store it.

[0059] 2) Weigh 20g of saline-alkali soil to be improved and adsorbed SO 2 After 4A molecular sieve 1g, adsorb SO 2 The final 4A molecular sieve is used as a saline-alkali soil improver, that is, the amount of the improver to be improved is 5% compared to the saline-alkali soil to be improved. After thorough mixing, put it into a 20ml centrifuge tube and add a certain amount of deionized water.

[0060] 3) Put the mixture obtained in step 2) into an incubator, maintain the temperature at 25±2° C., and the humidity at 40%.

Embodiment 2

[0062] 1) Provide a certain amount of saline-alkali soil to be improved, air-dry the saline-alkali soil to be improved for several days, sieve through a 20-mesh sieve, and store it.

[0063] 2) Weigh 20g of the saline-alkali soil to be improved and the SO absorbing 2 The final 4A molecular sieve is 3g, that is to say, the addition amount of the improvement agent is 15% compared with the saline-alkaline soil to be improved. After thorough mixing, put it into a 20ml centrifuge tube, and add a certain amount of deionized water.

[0064] 3) Put the mixture obtained in step 2) into an incubator, maintain the temperature at 25±2° C., and keep the humidity at 50%.

Embodiment 3

[0066] 1) Provide a certain amount of saline-alkali soil to be improved, air-dry the saline-alkali soil to be improved for several days, sieve through a 20-mesh sieve, and store it.

[0067] 2) Weigh 20g of the saline-alkaline soil to be improved and 3g of the 4A molecular sieve after absorbing NOx, and the 4A molecular sieve after absorbing NOx is used as the modifier of the saline-alkali soil to be improved, that is, to maintain the amount of the modifier compared to the saline-alkali soil to be improved 15%, put it into a 20ml centrifuge tube after thorough mixing, and add a certain amount of deionized water.

[0068] 3) Put the mixture obtained in step 2) into an incubator, maintain a temperature of 25±2° C., and a humidity of 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com