Temperable film-coated glass having composite functional thin film and preparation method thereof

A composite function, coated glass technology, applied in the direction of layered products, coatings, etc., to achieve the effect of saving power consumption, reducing customer processing and packaging transportation costs, and expanding the radiation radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

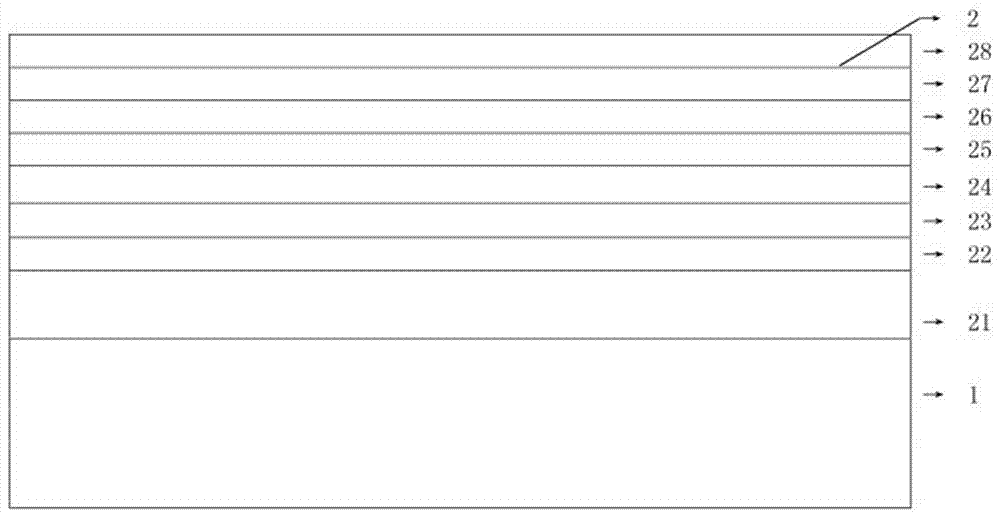

[0047] A temperable coated glass with a composite functional film, comprising a glass substrate 1, on the composite surface of the glass substrate, 8 film layers are compounded sequentially and adjacently from the inside to the outside, the Si of the first film layer 3 N 4 The thickness of layer 21 is 38nm; The thickness of the AZO layer 22 of described second film layer is 6nm; The thickness of the NiCr layer 23 of described third film layer is 8nm; The thickness of the Ag layer 24 of described 4th film layer is 32nm; the thickness of the NiCr layer 25 of the fifth film layer is 8nm; the thickness of the AZO layer 26 of the sixth film layer is 6nm; the Si of the seventh film layer 3 N 4 The thickness of layer 27 is 38nm; The Si of the eighth film layer 3 N x o y Layer 28 has a thickness of 12 nm. The AZO layer structure of the second layer and the sixth layer can also be ZnO 2 , SnO 2 The composite structure layer with a thickness of 8 nm.

[0048] Among them, the fir...

Embodiment 2

[0055] A temperable coated glass with a composite functional film, comprising a glass substrate 1, on the composite surface of the glass substrate, 8 film layers are compounded sequentially and adjacently from the inside to the outside, the Si of the first film layer 3 N 4 The thickness of layer 21 is 34nm; The thickness of the AZO layer 22 of described second film layer is 7nm; The thickness of the NiCr layer 23 of described third film layer is 6nm; The thickness of the Ag layer 24 of described 4th film layer is 30nm; the thickness of the NiCr layer 25 of the fifth film layer is 6nm; the thickness of the AZO layer 26 of the sixth film layer is 7nm; the Si of the seventh film layer 3 N 4 The thickness of layer 27 is 34nm; The Si of the eighth film layer 3 N x o y Layer 28 has a thickness of 10 nm. The AZO layer structure of the second layer and the sixth layer can also be ZnO 2 , SnO 2 The composite structure layer with a thickness of 6 nm.

[0056] The above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap