Thermosetting resin composition, prepreg containing same, metal foil-coated laminate and printed circuit board

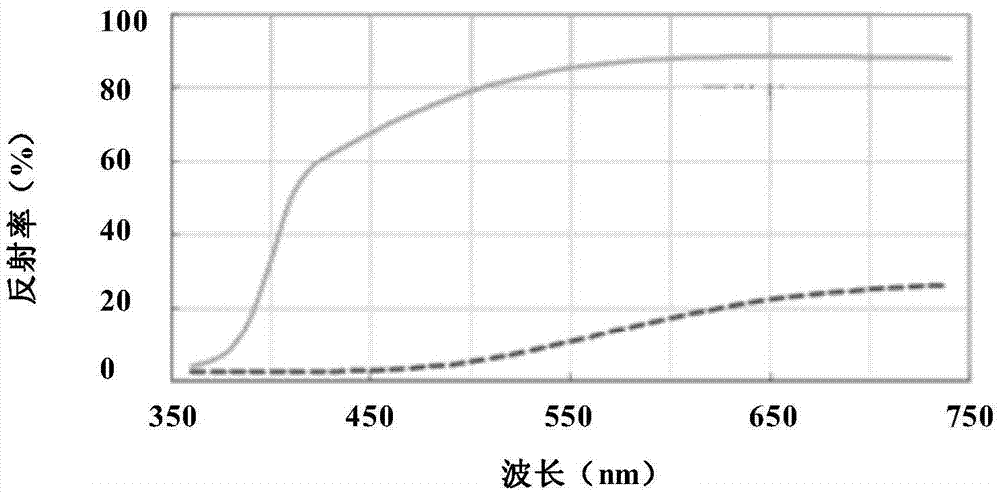

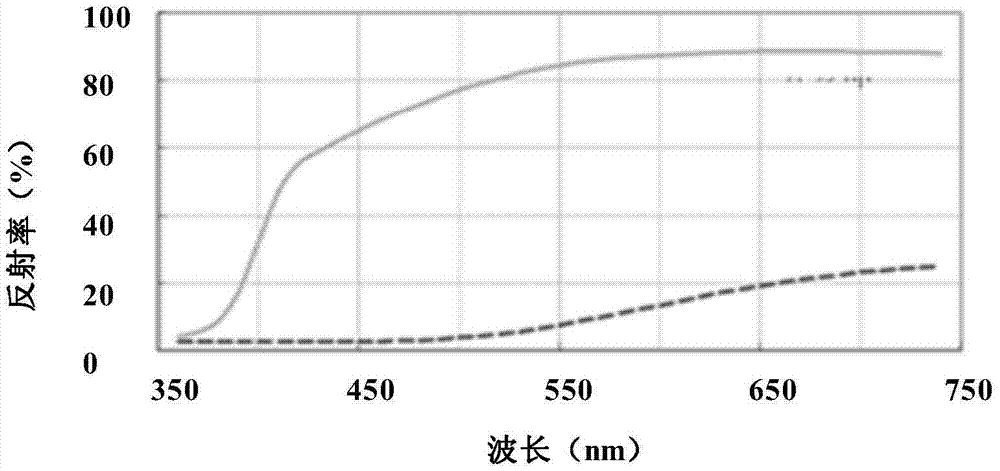

A resin composition and thermosetting technology, applied in the field of laminate materials, can solve the problems of low viscosity stability, poor preservation, heat resistance, light aging resistance, and the improvement of water absorption and other properties is not obvious, and achieves low water absorption, Low cost and excellent drilling workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

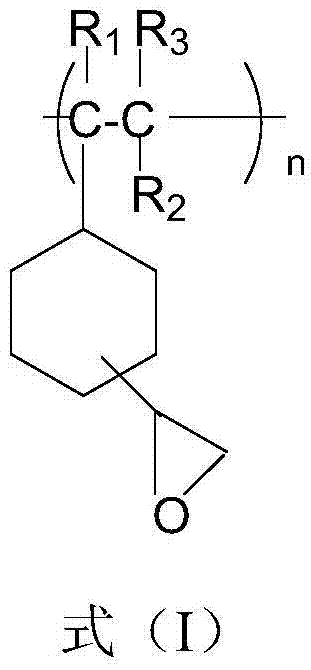

[0043] In the present embodiment, the cycloaliphatic epoxy resin used has the structure shown in the following formula (I)-1:

[0044]

[0045] Use 29.95 parts of bisphenol A type cyanate ester, 35 parts of alicyclic epoxy resin (I)-1, 0.05 part of 2-methylimidazole, 15 parts of SPB100 (phosphazene flame retardant, Japan Otsuka), 20 parts Titanium dioxide, using appropriate amount of methyl ethyl ketone and toluene to dissolve the above compounds, and prepare a glue with a suitable viscosity. Use this glue solution to impregnate 1078 electronic grade glass cloth, and remove the solvent in an oven at 115°C to obtain a B-stage prepreg sample with a resin content of 54%.

[0046] Two sheets of prepreg prepared above and two sheets of one ounce electrolytic copper foil were stacked together, and laminated by a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the temperature of the material is 80°C to 120°C, the heating ...

Embodiment 2

[0048] In the present embodiment, the cycloaliphatic epoxy resin used has structure shown in following formula (1)-2:

[0049]

[0050] Use 24.95 parts of EPIKOTE828EL bisphenol A epoxy resin (Dow Chemical), 40 parts of alicyclic epoxy resin (I)-2, 0.05 parts of 2-methylimidazole, 15 parts of SPB100 (Japan Otsuka), 20 parts of titanium dioxide , using proper amount of methyl ethyl ketone and toluene to dissolve the above compound, and prepare a glue solution with suitable viscosity. Use this glue solution to impregnate 1078 electronic grade glass cloth, and remove the solvent in an oven at 115°C to obtain a B-stage prepreg sample with a resin content of 54%.

[0051] Two sheets of prepreg prepared above and two sheets of one ounce electrolytic copper foil were stacked together, and laminated by a hot press to obtain a double-sided copper-clad laminate. The lamination conditions are as follows: 1. When the temperature of the material is 80°C to 120°C, the heating rate is co...

Embodiment 3

[0053] In the present embodiment, use the alicyclic epoxy resin of the structure shown in the formula (I)-1 identical with embodiment 1, and difference only is that the consumption of bisphenol A type cyanate is 58.95 parts, and formula (I) The consumption of the cycloaliphatic epoxy resin with the structure shown in -1 is 6 parts, and the rest of the ingredients and the dosage of the ingredients are the same as those in Example 1. They are produced and tested according to the method of Example 1, and the corresponding properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com