Aluminum alloy panel for automobile body lightweight and preparing method of aluminum alloy panel

An aluminum alloy sheet, lightweight technology, applied in the field of aluminum alloy processing, can solve the problems of difficult to achieve high formability, high strength, general performance and other problems, achieve the elimination of dendrite structure and low melting point eutectic structure, ensure comprehensive performance, The effect of increasing strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

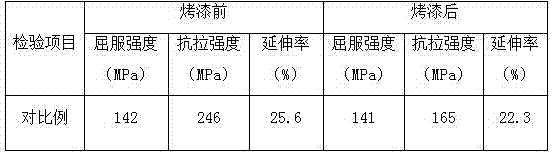

Examples

Embodiment 1

[0032] The chemical composition of the aluminum alloy sheet is by mass percentage:

[0033]Mg:1.2-2.2%, Si:0.8-1.5%, Fe:0.1-0.3%, Mn:0.2-0.8%, Cu:0.2-0.5%, Zr:0.05-0.2%, Cr:0.01-0.5%, La :0.05-0.2%, Zn≤0.2%, Ti≤0.1%, individual content of other impurity elements≤0.05%, total content of other impurity elements≤0.15%, and the balance is Al.

[0034] Its preparation method is:

[0035] (1) Melting: first put the aluminum ingot into the vacuum melting furnace for smelting. After the aluminum ingot starts to melt, add instant silicon, aluminum-manganese master alloy, aluminum-chromium master alloy and aluminum-zirconium master alloy. After the aluminum ingot is completely melted, add cathode copper and For magnesium ingots, add refining agent during the smelting process, and remove slag from the aluminum melt. After analyzing the composition of the aluminum melt, it is transferred to the holding furnace. The melting temperature is 720-750°C, and the smelting time is 4-8 hours. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com