Method for increasing low-temperature impact energy of nuclear reactor pressure vessel steel large-scale thick-wall forged piece

A technology for pressure vessels and nuclear reactors, applied in the field of heat treatment of steel, can solve the problems of deterioration of low-temperature toughness, microstructure differences, etc., and achieve the effects of improving low-temperature impact toughness, good mechanical properties, and high use safety margin value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

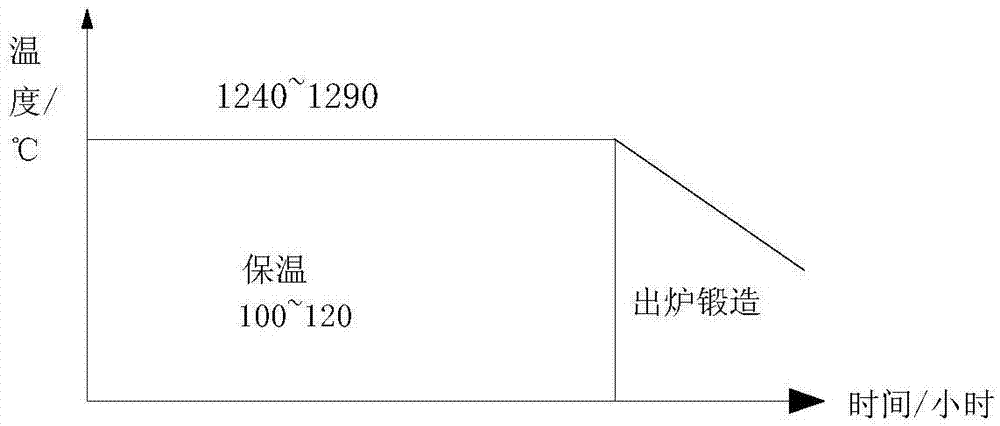

[0060] The method for increasing the low-temperature impact energy of a large thick-walled forging of a nuclear reactor pressure vessel steel of the present invention is suitable for thick-walled forgings whose material is SA-508Gr.

[0061] The first step is to smelt steel ingots;

[0062] The composition of steel ingot is (this text is all mass percent content):

[0063] C: 0.18~0.20%,

[0064] Mn: 1.40~1.50%,

[0065] P≤0.008%,

[0066] S≤0.005%,

[0067] Si: 0.25~0.40%,

[0068] Ni: 0.80~0.95%,

[0069] Cr≤0.25%,

[0070] Mo: 0.45~0.50%,

[0071] V≤0.05%,

[0072] Al: 0.020~0.030%,

[0073] N: 0.020~0.030%,

[0074] O≤0.003%,

[0075] H≤0.0002%;

[0076] The ASME SA508 / 508M (2004 edition) standard specifies the composition of SA-508Gr.3Cl.1, but the specified composition range is too broad, and the hot working characteristics of forgings fluctuating within its range have significant differences. The present invention further limits the composition of each elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com