A method of removing nitriding salt bath slag by using the principle of magnetic adsorption

A magnetic adsorption and salt bath technology, applied in chemical instruments and methods, magnetic separation, solid-state diffusion coating, etc., can solve the problems of blocking production efficiency and low efficiency, and achieve the effects of easy operation, enhanced suction, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

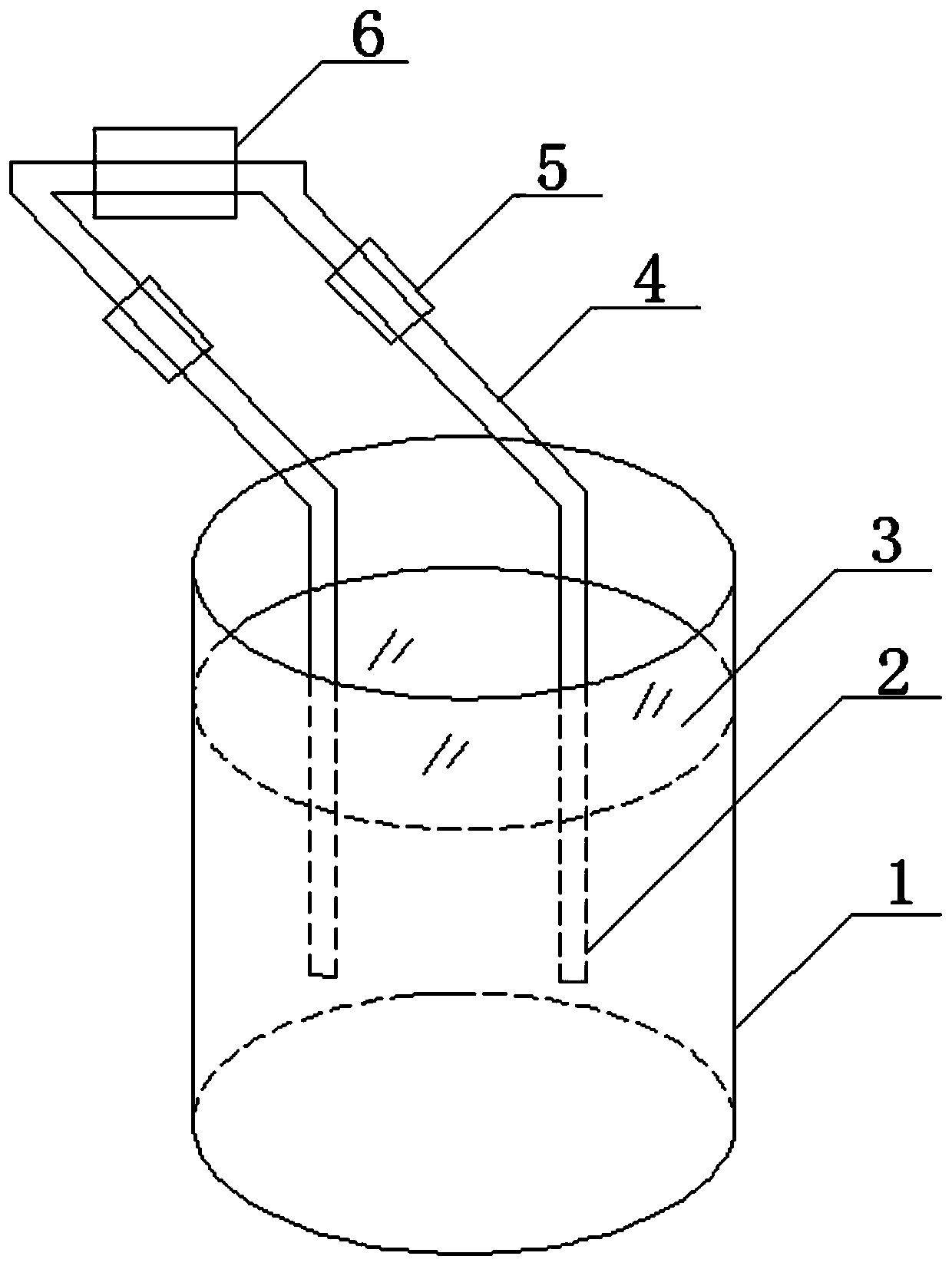

[0030] The mode that the external magnet acts on the salt bath is that the magnetic pole 2 of the shoe-shaped iron core 4 is stretched in the salt bath 3, directly the magnetic pole 2 of the shoe-shaped iron core 4 is put into the salt bath 3, and the magnetic device 6 makes the shoe-shaped iron After the core 4 is magnetized, the effect of absorbing slag can be achieved, the structure is simple, easy to operate, and the cost is low.

Embodiment 2

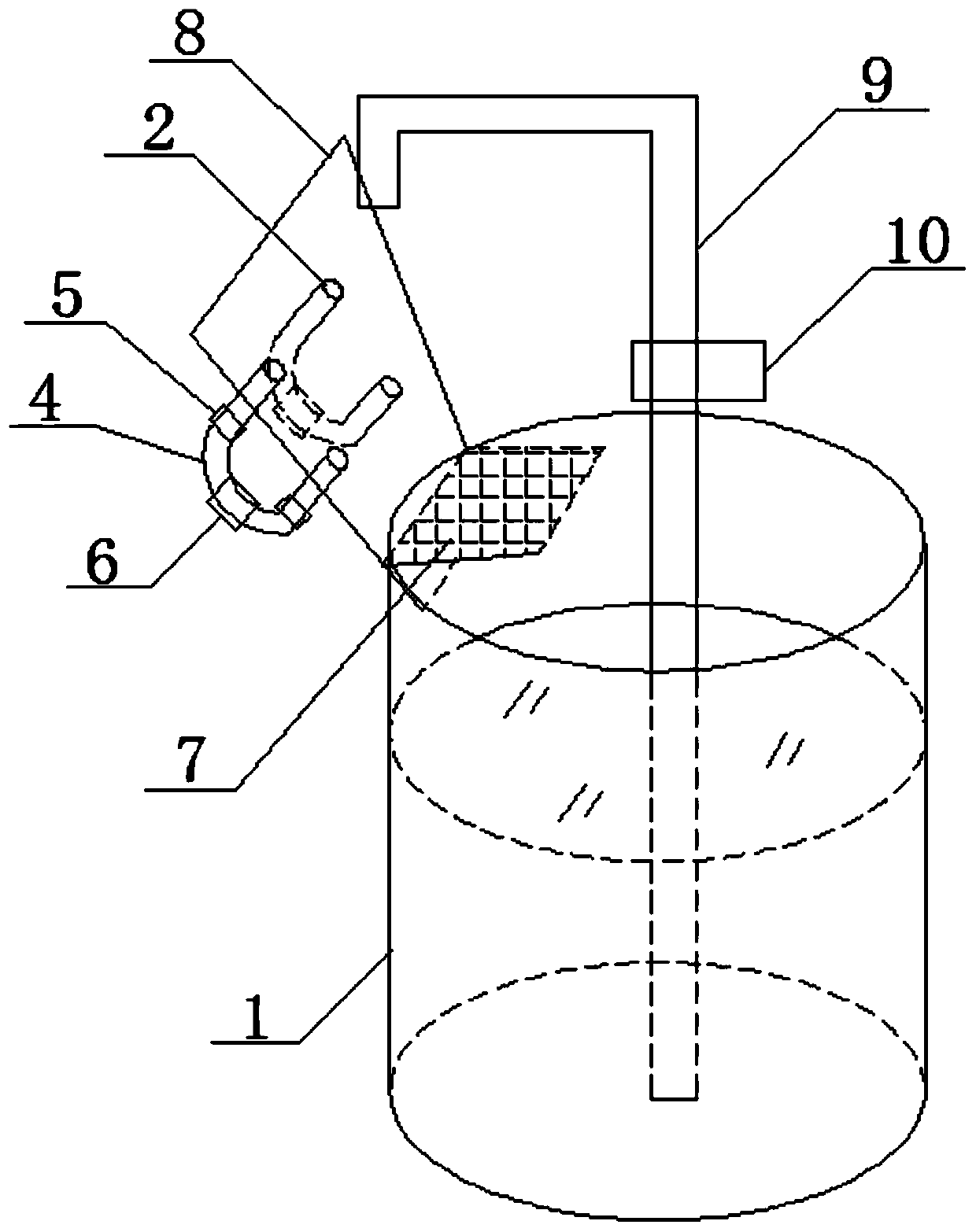

[0032] The way that an external magnet acts on the salt bath is to extract the salt bath and flow through the magnetic pole 2 of the shoe-shaped iron core 4, specifically: extract the salt bath 3 from the nitride salt bath 1 containing the salt bath 3 and make the salt bath 3 The flow passes through a sloping plate 8 arranged above the nitride salt bath 1 , so that the salt bath 3 contacts the magnetic pole 2 arranged on the sloping plate 8 . A salt extraction pipeline 9 can be set, one end of the salt extraction pipeline 9 is placed in the nitride salt bath 1, the other end is placed above the deflector swash plate 8, and a circulation pump 10 is set on the salt extraction pipeline 9 to remove the salt bath from the nitriding The salt bath is extracted from the salt bath tank 1 and flows to the deflector inclined plate 8 through the salt extraction pipe 9 to remove the slag, and the salt bath from which the slag is removed finally flows back to the nitride salt bath tank 1 to ...

Embodiment 3

[0035] Based on the above embodiment, the shoe-shaped iron core 4 between the magnetic pole 2 and the magnetic device 6 is provided with a cooling package 5, which can prevent the high temperature of the salt bath from being transmitted to the magnetic device 6 and affect the magnetization effect of the shoe-shaped iron core 4. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com