Wheel type explosive motor

A technology of internal combustion engine and wheel type, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of high operating noise, high manufacturing cost, poor reliability and durability, etc., and achieve low vibration and noise, large Development advantage, effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

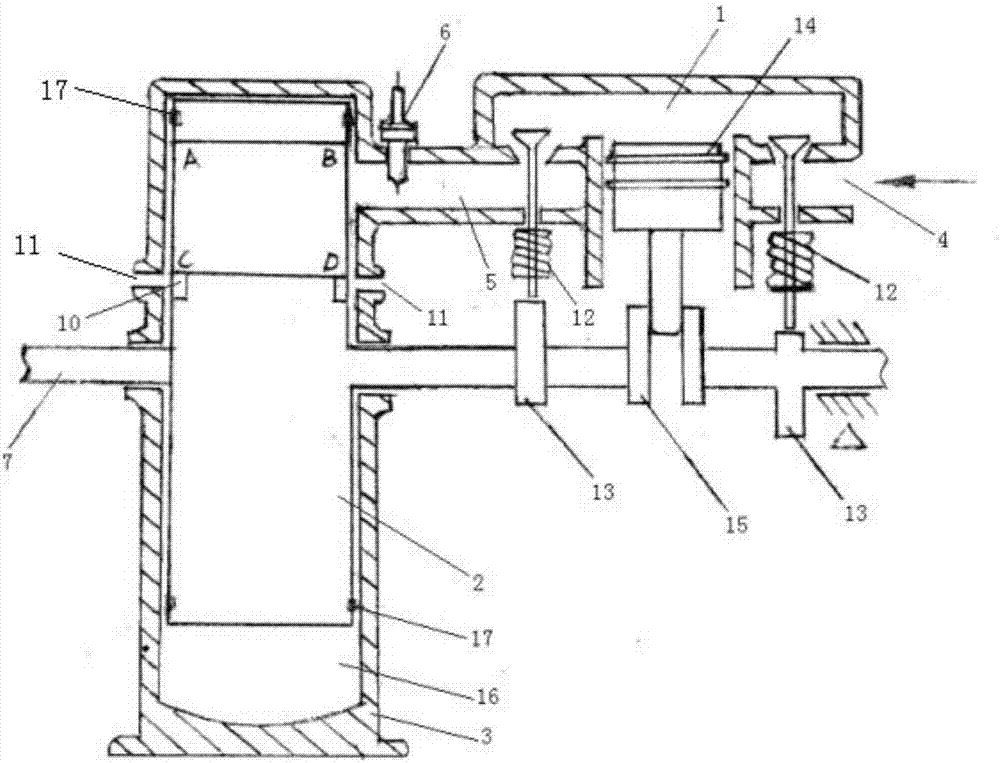

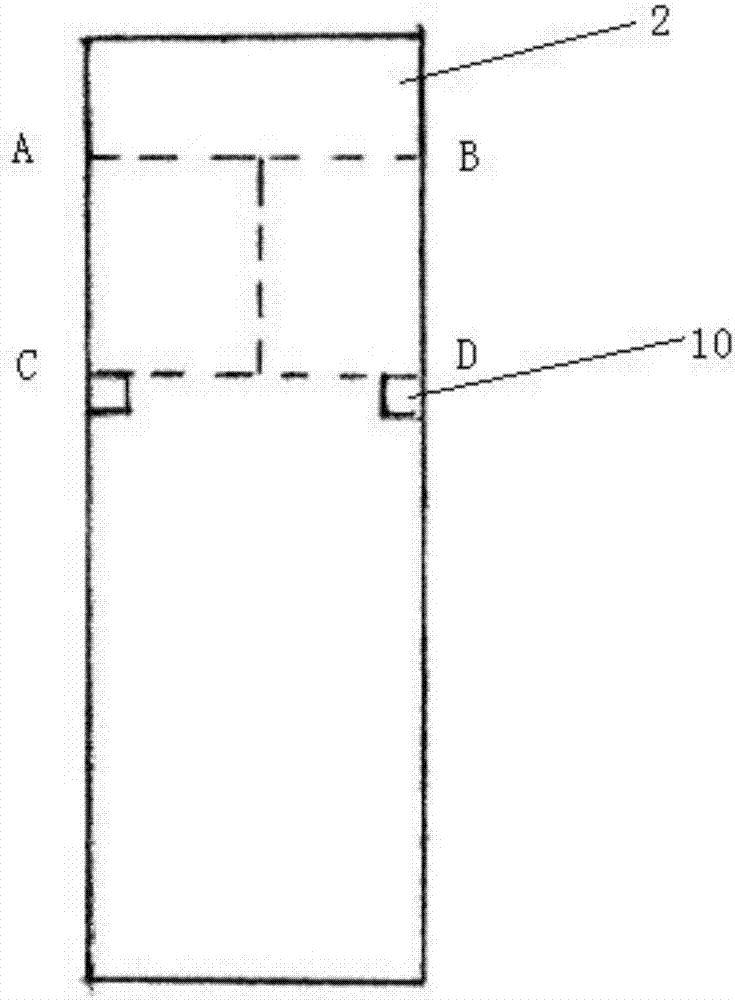

[0034] Such as figure 1 As shown, a wheel-type internal combustion engine includes a mixed gas compression chamber 1, a transmission wheel 2 and a housing 3; one end of the mixed gas compression chamber 1 is provided with an inlet 4 for sending mixed gas into its interior, and the mixed gas The other end of the steam compression chamber 1 is provided with an outlet 5 for discharging the compressed mixed steam inside, and the outlet 5 communicates with the inside of the housing 1, and the inlet 4 or the outlet 5 is provided with a Switch valve 12. One end of the rotating shaft 7 passes through the housing 3 and extends towards the direction of the mixed gas compression chamber 1, and the rotating shaft 7 is provided with a valve 12 corresponding to the top pressure to switch the inlet 4 or the The two cams 13 of the outlet 5, the cams 13 are respectively located on the rotating shaft 7 and corresponding to the position of the inlet 4 and the position corresponding to the outle...

Embodiment 2

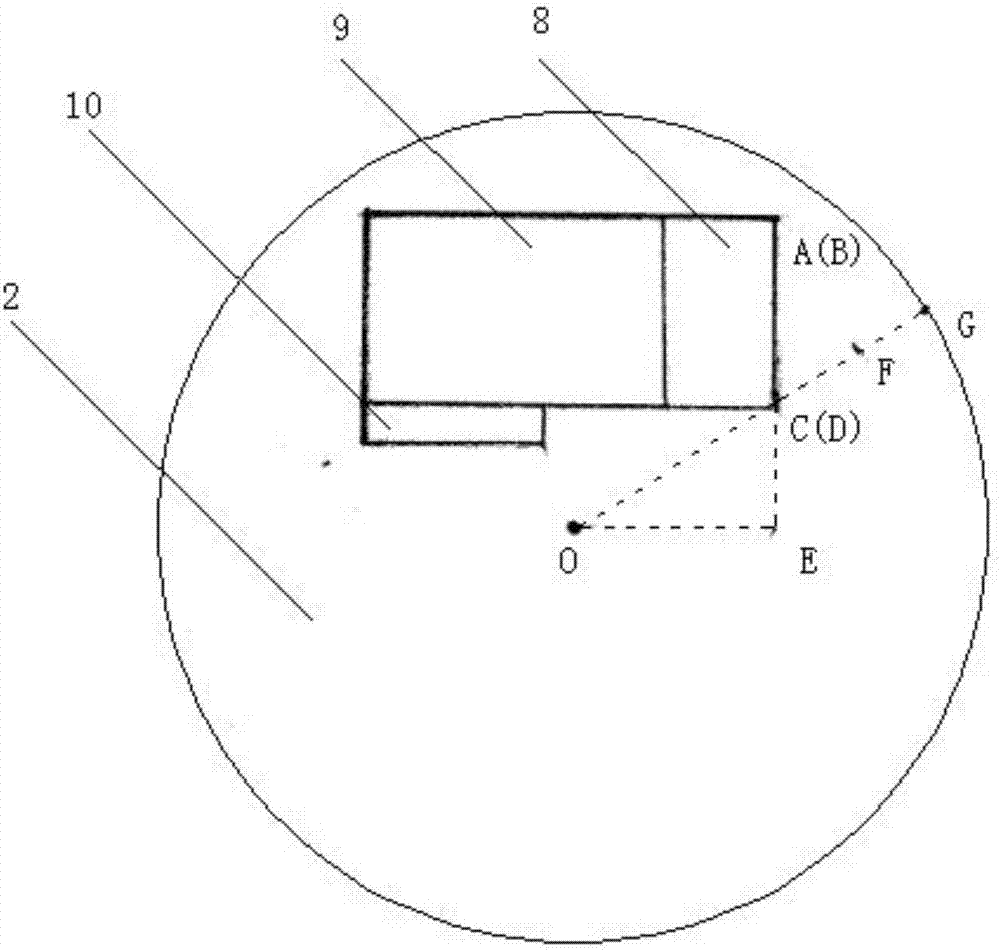

[0045] Such as Figure 6 As shown, the cavity 8 is designed as a through hole of the fan structure through which the transmission wheel 2 axially penetrates, and the elimination mechanism 9 is designed as a fan structure matching the cavity 8, and one end with a circular arc surface faces the cavity The opposite side of 8 extends, and all the other structures are identical with embodiment one.

[0046] The elimination mechanism 9 is a fan structure, and its two sides are also two opposite slopes, and the work done on the elimination mechanism 9 after the explosion of the mixed gas can also be offset. In addition, because the cavity 8 is a fan structure matched with the elimination mechanism 9, the side of the cavity 8 is the force arm of the opposite side of the elimination mechanism 9 after the explosion of the mixed gas (the force arm is image 3 OF in, wherein F is the midpoint of CG; the moment arm in the first embodiment is OE, according to the right triangle theorem, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com