Method for injection loading explosive and powder loading structure damaging real-time monitoring

A technology for real-time monitoring and structural damage, applied in measuring devices, measuring heat, using optical devices, etc., can solve the problems of undetectable, increased risk, long X-ray scanning time, etc., achieve fast response time, reduce test risk, Monitoring the effectiveness of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

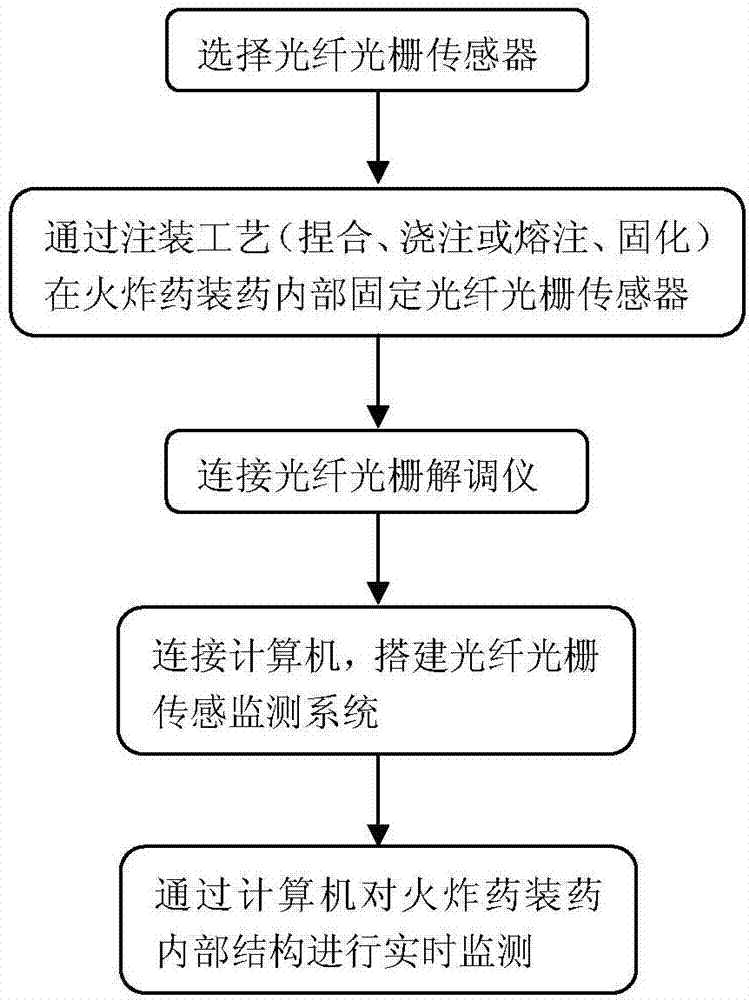

Method used

Image

Examples

Embodiment 1

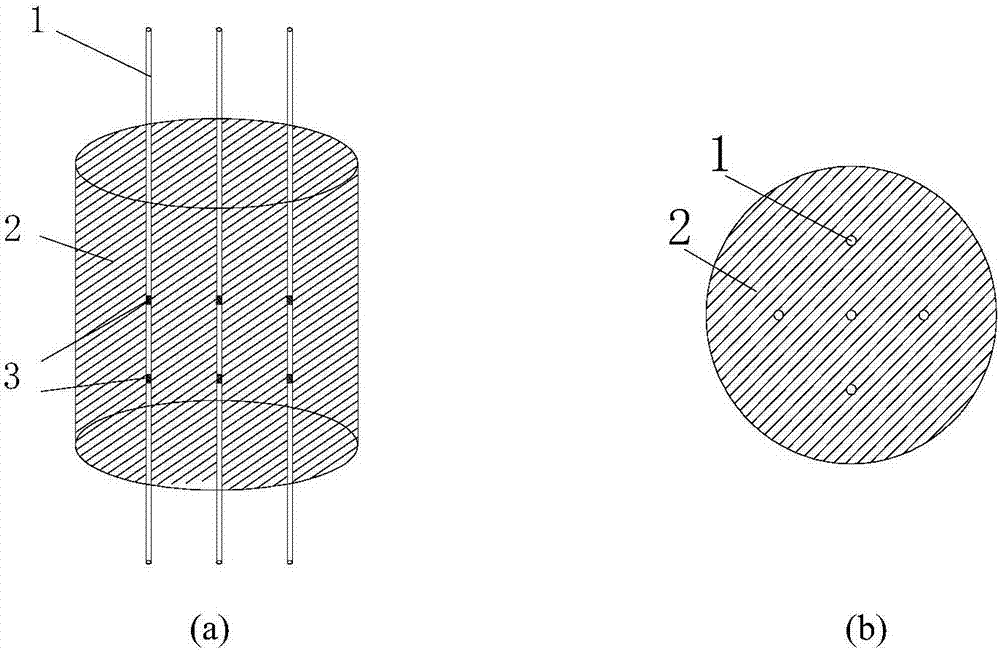

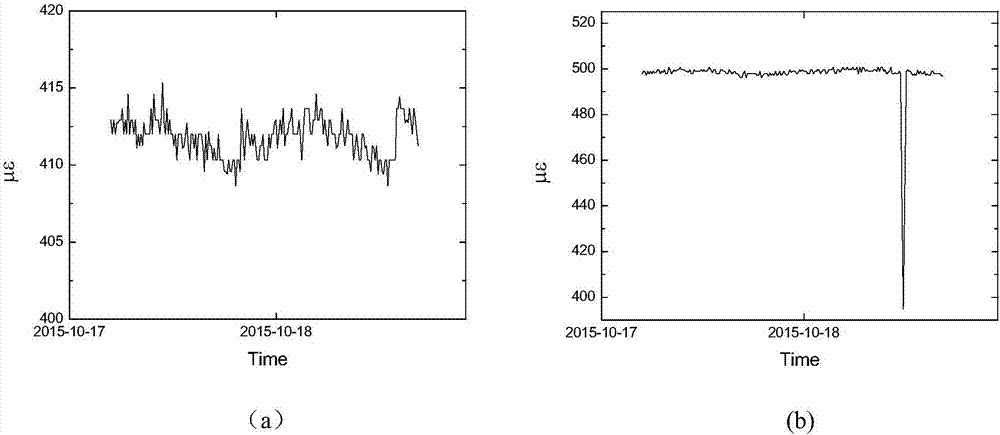

[0021] The research object is a new type of gel-state propellant and explosive developed by our unit, and thermally accelerated aging test is carried out on it. The new gel state propellant and explosive is in the gel state at room temperature, and its gel state may change when the ambient temperature changes, resulting in changes in the internal charge structure of the system. The traditional detection method is CT detection. The detection time of this method is long, real-time monitoring cannot be achieved, and the detection cannot be directly carried out in the warehouse where the explosives are stored, and the danger is increased during the handling process. The fiber grating sensing monitoring system can monitor the internal stress / strain changes of the new gel-state propellant and explosive system in the airtight container. The sample does not need to be moved, and the detection process realizes human-machine isolation, ensuring the safety of the experimenters, and the d...

Embodiment 2

[0034] Since the FBG sensor responds to stress, strain and temperature at the same time, in order to ensure the accuracy of the test results, it needs to be packaged when using the FBG sensor to measure the ambient temperature, so as to eliminate the influence of strain on the test results. The inner diameter of the tube used to package the temperature sensor should be larger than the outer diameter of the fiber grating, and the influence on the internal structure and mechanical properties of the charge should be reduced as much as possible. After market research and experimental demonstration, a medical needle with a diameter of 0.03mm was finally selected to package the fiber grating sensor. When packaging, put the fiber grating sensor into the medical needle, seal the two ends with epoxy glue, and let it stand for 12 hours to cure.

[0035] A. Select the initial wavelength λ 0 Single FBG fiber grating sensor with fc / apc interface in the range of 1510nm-1590nm, packaged wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com