Pressure sensor with double graphite resonant beams

A pressure sensor, graphene technology, applied in elastic deformation meter type fluid pressure measurement, measurement of fluid pressure, measurement of fluid pressure through electromagnetic components, etc., can solve the problem of increasing design cost and production cycle, affecting the stability of the sensor, Sensor measurement accuracy and other issues, to achieve the effect of shortening design cost and production cycle, ensuring performance, and improving anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

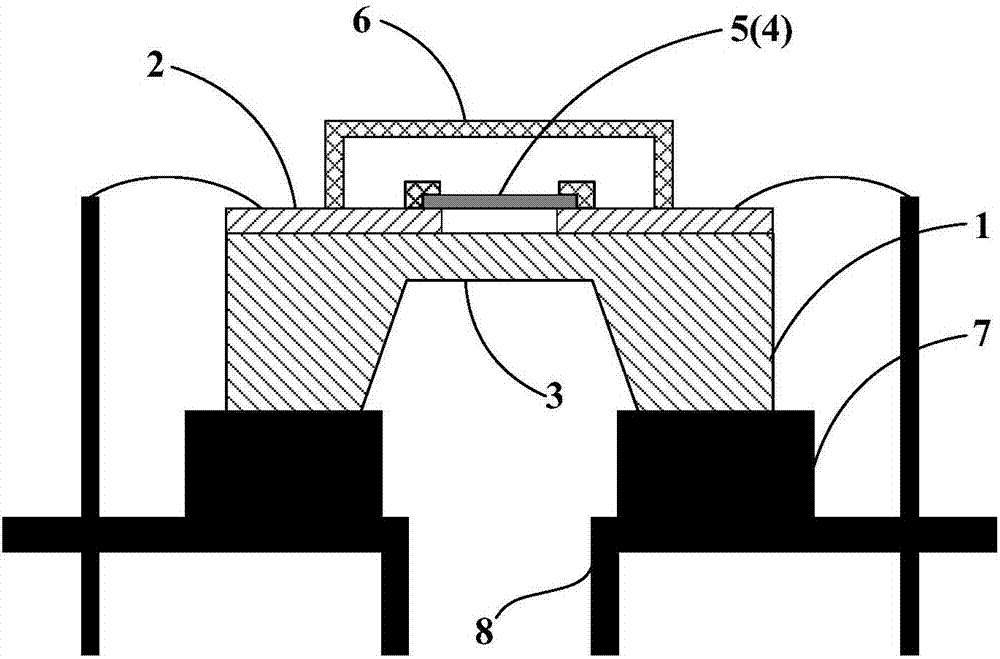

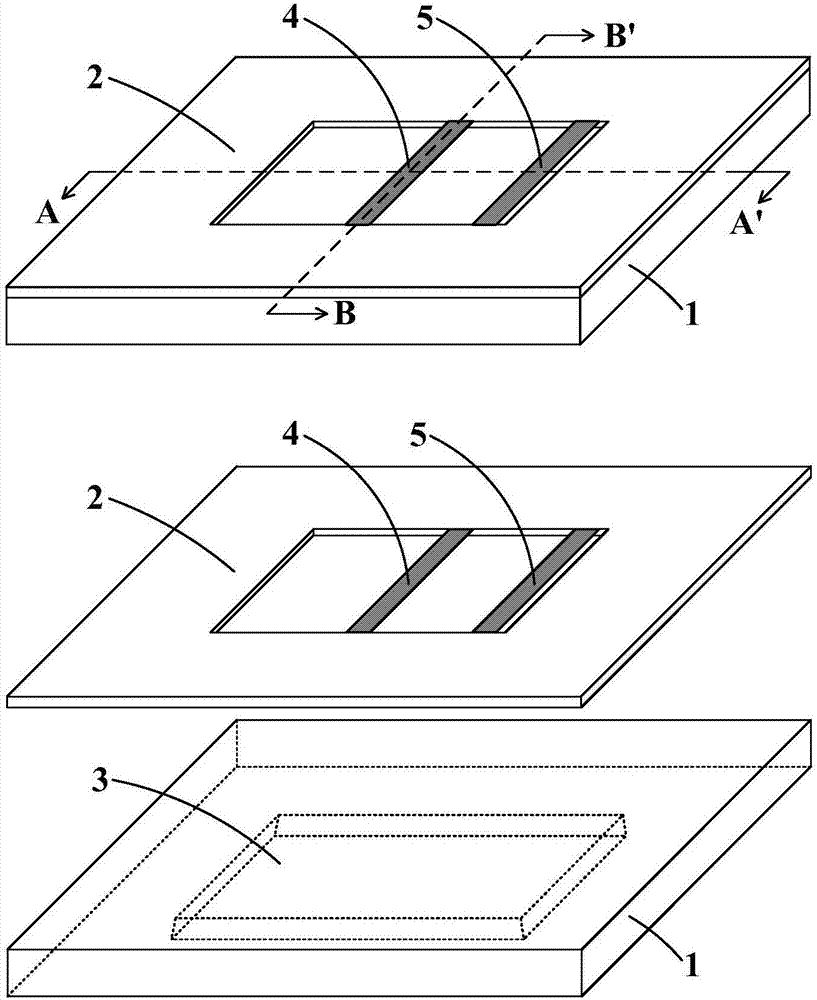

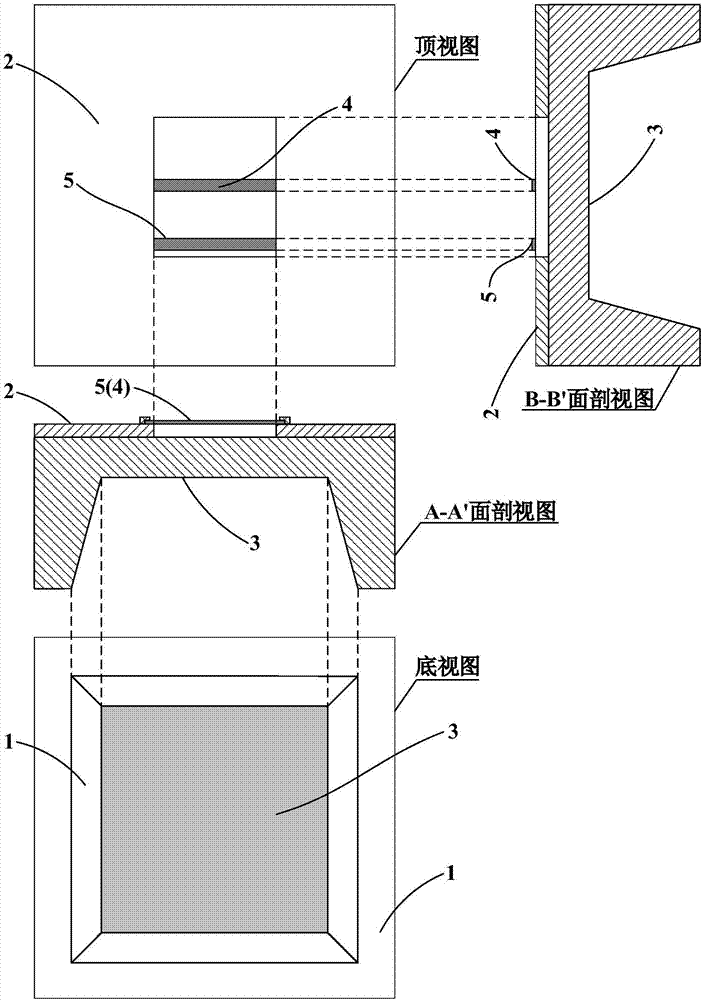

[0029] Such as figure 1 , figure 2 , image 3 As shown, a kind of double graphene resonant beam type pressure sensor of the present embodiment comprises substrate 1, insulating layer 2, square flat diaphragm 3, the first graphene resonant working beam 4, the second graphene resonant working beam 5, Vacuum sealing cover 6, support 7 and pressure guiding tube 8. In the embodiment, the substrate 1 is made of single crystal silicon, and the insulating layer 2 is made of silicon dioxide as an example. The vacuum sealing cover 6 provides a vacuum environment, the support 7 is used as a support for the sensor, and the pressure guide tube 8 introduces the measured pressure. Among them, a square deep groove is etched in the central area of the bottom of the original wafer to form a substrate 1 and a square flat diaphragm 3; the surface of the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com