A method for regulating the digestibility of highland barley starch and modified highland barley starch

A technology of highland barley and starch, which is applied in the field of regulating the slow digestion and anti-digestion performance of highland barley starch, can solve the problems that starch granules are prone to excessive degradation and easy digestion, and achieve the improvement of slow digestion and anti-digestion performance, improvement of anti-digestion performance, and treatment A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

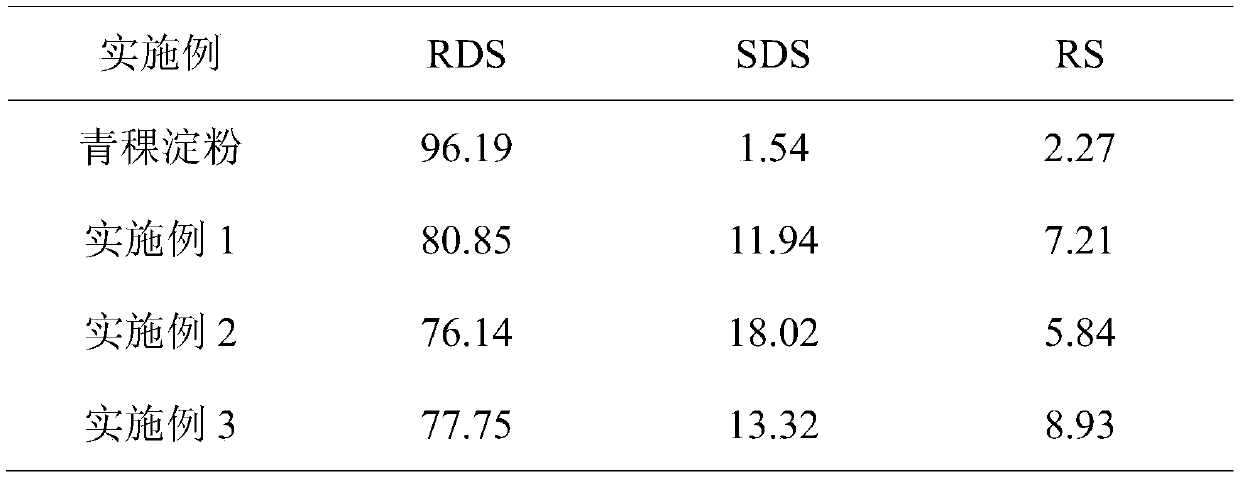

Embodiment 1

[0021] 200g of highland barley starch with a moisture content of 10% is placed in a fluidized bed, heated so that the temperature of the highland barley starch is 180°C, the fluidization pressure is controlled to be 0.01MPa, and the speed of the turntable is 500rpm, so that the highland barley starch is in a fluidized state , then under the atomization pressure of 0.06MPa, according to the amount of 0.5% dry weight of highland barley starch, 9ml of 10% sodium hydroxide solution is sprayed on the fluidized highland barley starch by tangential spraying at a speed of 0.5ml / min During the process, the fluidized heat treatment was maintained for 0.5h, and the fluidized heat treated highland barley starch was obtained after cooling.

Embodiment 2

[0023] 200g of highland barley starch with a moisture content of 20% is placed in a fluidized bed, heated so that the temperature of the highland barley starch is 120°C, the fluidization pressure is controlled to be 0.05MPa, and the speed of the turntable is 600rpm, so that the highland barley starch is in a fluidized state , then under the atomization pressure of 0.1MPa, according to the amount of 1% dry weight of highland barley starch, 10ml of 16% sodium hydroxide solution is sprayed on the fluidized highland barley by tangential spraying at a speed of 1.0ml / min. For starch, keep the fluidized heat treatment for 1.5 hours, and then get the fluidized heat treated highland barley starch after cooling.

Embodiment 3

[0025]150g moisture content is that the highland barley starch of 30% is placed in the fluidized bed, heating makes the highland barley starch temperature be under the condition of 100 ℃, regulates the fluidization pressure to be 0.1MPa, and the turntable speed is 1000rpm, makes the highland barley starch in the fluidized state, Then, under the atomization pressure of 0.1MPa, according to the amount of 2% of the dry weight of highland barley starch, 21ml of 10% sodium hydroxide solution is sprayed on the fluidized highland barley starch by tangential spraying at a speed of 0.6ml / min. During the process, keep the fluidized heat treatment for 2.5 hours, and then get the fluidized heat-treated highland barley starch after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com