Preparation method of food-grade immune globulin G micro-emulsion with gastric acid resisting protection effect

A technology of immunoglobulin and protective effect, which is applied in the field of preparation of food-grade immunoglobulin G microemulsion with gastric acid-resistant protective effect, and can solve problems such as industrial production difficulties, waste of raw materials, and application limitations of bovine colostrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

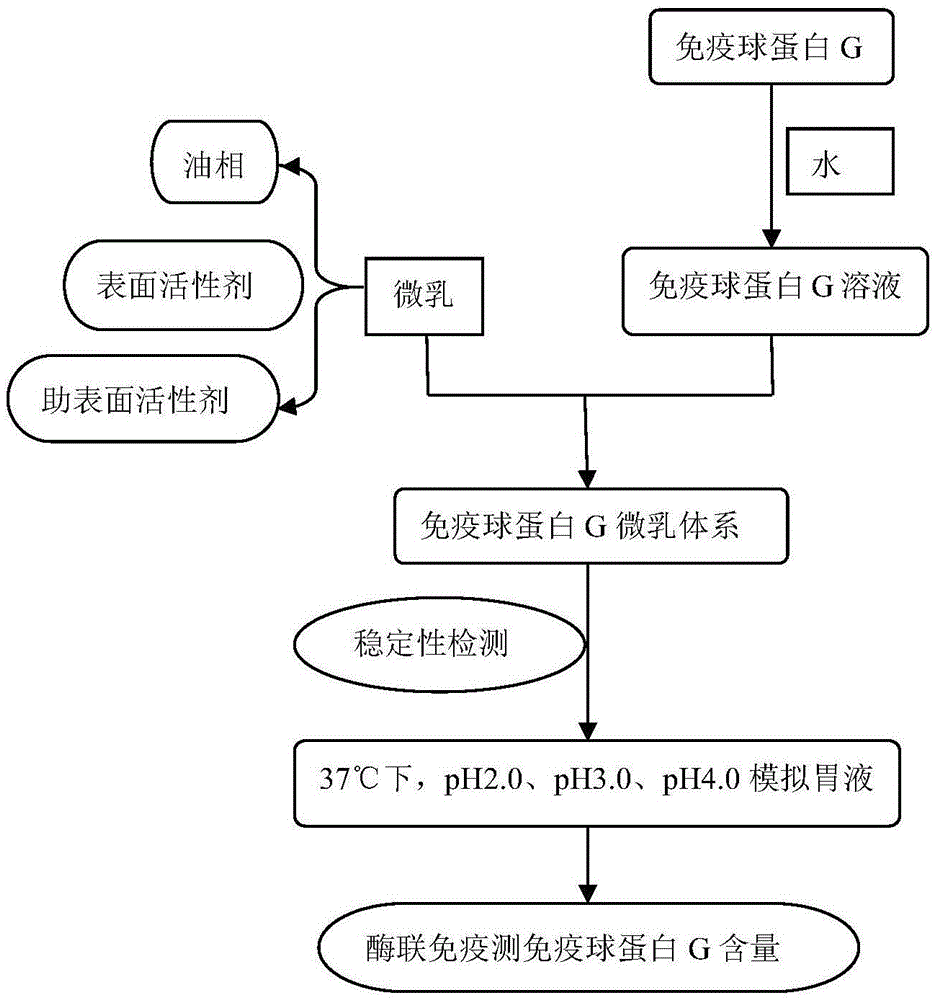

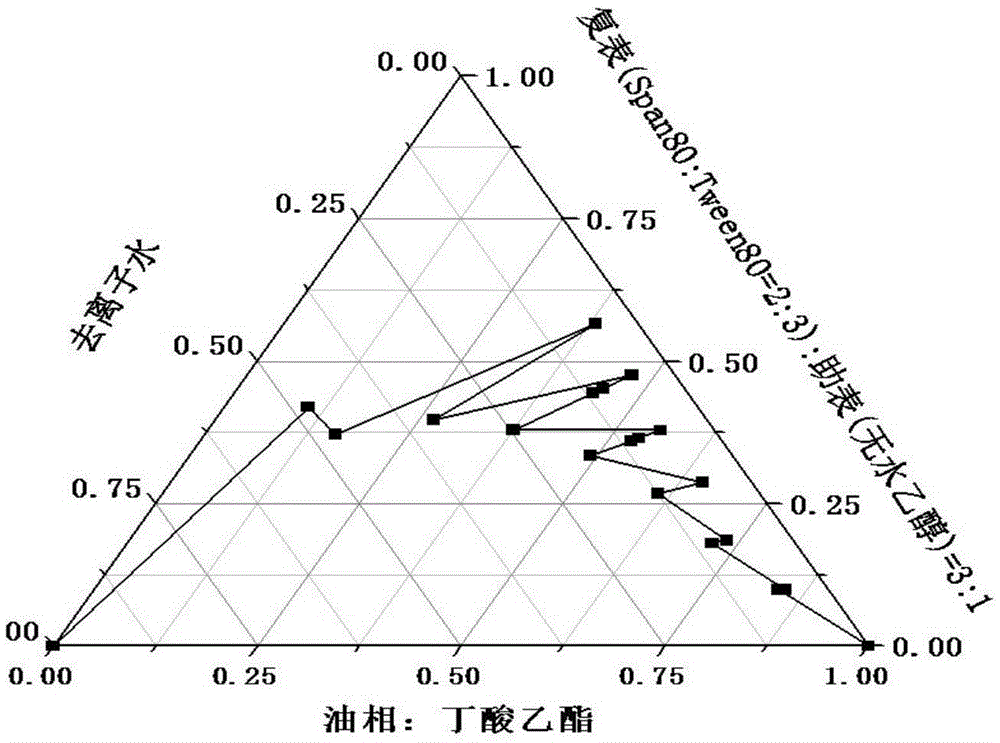

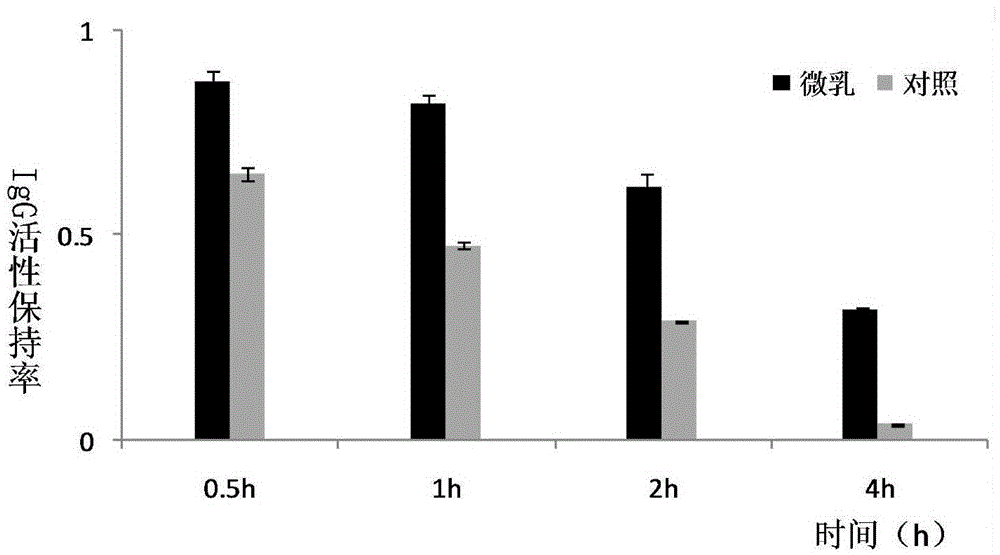

[0013] A preparation method of food-grade immunoglobulin G microemulsion with gastric acid-resistant protective effect, the method comprising the following steps: (1) mixing 11-13 milliliters of Span80 and 16-20 milliliters of Tween80, adding 50-70 milliliters of ethyl butyrate Esters are combined into a composite surfactant; (2) in the composite surfactant obtained in step (1), add 8 to 12 milliliters of cosurfactant dehydrated alcohol to obtain a composite surfactant; (3) at room temperature At 25°C, add 10 milliliters of immunoglobulin G solution dropwise to the composite active agent obtained in step (2) while stirring on a magnetic stirrer, the concentration of immunoglobulin G solution is 10 mg / mL, and the concentration of immunoglobulin G is 10 mg / mL. The solvent of the solution is deionized water; (4) the prepared immunoglobulin G microemulsion samples are subjected to a gastric acid resistance test, and the artificial gastric juices with pHs of 2.0, 3.0, and 4.0 are re...

Embodiment 1

[0017] (1) Mix 11 milliliters of Span80 and 16 milliliters of Tween80, add 50 milliliters of ethyl butyrate to form a compound surfactant.

[0018] (2) In the composite surfactant obtained in step (1), add 8 milliliters of cosurfactant dehydrated alcohol, obtain composite surfactant.

[0019] (3) At room temperature at 25°C, add 10 milliliters of immunoglobulin G solution dropwise to the composite active agent obtained in step (2) while stirring on a magnetic stirrer, and the concentration of the immunoglobulin G solution is 10 mg / mL , the solvent of the immunoglobulin G solution is deionized water.

[0020] (4) The prepared immunoglobulin G microemulsion samples were subjected to gastric acid resistance test, and were treated in artificial gastric juice with pH of 2.0, 3.0, and 4.0 in a stirring water bath at 37°C for different periods of time.

[0021] (5) After the samples were taken out, they were rapidly cooled in cold water, and the content of immunoglobulin G in each s...

Embodiment 2

[0022] (1) Mix 11 milliliters of Span80 and 16 milliliters of Tween80, add 60 milliliters of ethyl butyrate to form a compound surfactant.

[0023] (2) In the composite surfactant obtained in step (1), add 10 milliliters of co-surfactant absolute ethanol to obtain the composite surfactant.

[0024] (3) At room temperature at 25°C, add 10 milliliters of immunoglobulin G solution dropwise to the composite active agent obtained in step (2) while stirring on a magnetic stirrer, and the concentration of the immunoglobulin G solution is 10 mg / mL , the solvent of the immunoglobulin G solution is deionized water.

[0025] (4) The prepared immunoglobulin G microemulsion samples were subjected to gastric acid resistance test, and were treated in artificial gastric juice with pH of 2.0, 3.0, and 4.0 in a stirring water bath at 37°C for different periods of time.

[0026] (5) After the samples were taken out, they were rapidly cooled in cold water, and the content of immunoglobulin G in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com