A process for the preparation of nano-starch by enzymatic hydrolysis of short amylose starch and self-assembly at medium temperature

A technology of short amylose and nano-starch, applied in fermentation and other directions, can solve the problems of low yield of nano-starch, long preparation time, large energy consumption, etc., and achieve the effects of environmental protection, simple operation, and increased yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

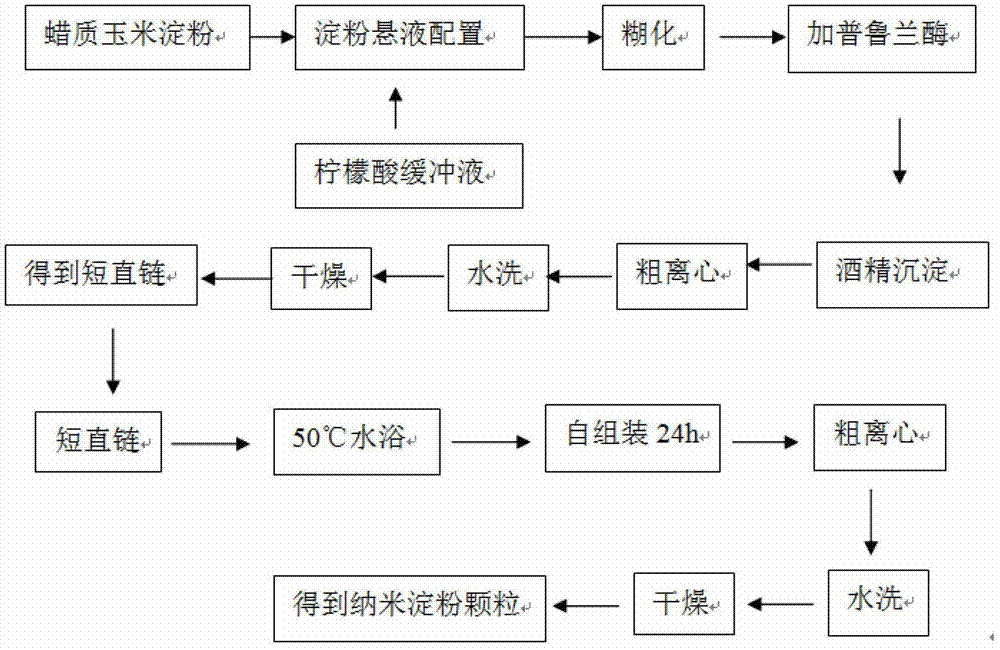

Method used

Image

Examples

preparation example Construction

[0050] (2) Preparation of starch aqueous solution: take degreased starch, add 100ml distilled water, and prepare starch milk solution with a concentration of 1-30%;

[0051] (3) Gelatinization: use citric acid buffer to adjust the pH of the starch solution to 4.6, and then heat it in a water bath for 30 minutes under boiling water bath conditions. During the gelatinization process, it is necessary to stir the starch continuously with a mixer so that the gelatinization is complete;

[0052](4) Enzymolysis: cool to about 58°C and add, add 4u / g pullulanase, the reaction conditions are to adjust the pH to 4.6, and react for 8 hours in a constant temperature water bath at 58°C; then use the degreased starch solution with 1:4 ethanol precipitation;

[0053] (5) Centrifuge the precipitated starch solution with a centrifuge to remove the supernatant to obtain a precipitate, and then wash it with water for 2-3 times. Freeze-drying obtains short amylopectin;

[0054] (6) Insulate the ...

Embodiment 1

[0072] A process for preparing nano-starch by enzymatically hydrolyzing short amylose at medium temperature self-assembly, the preparation method of which is as follows:

[0073] (1) Take by weighing 15g waxy cornstarch after degreasing, add 100ml distilled water, the starch milk solution of the 15% concentration of preparation; Regulate the pH of starch solution with citric acid buffer solution to be 4.6 and then heat in water bath under boiling water bath condition for 30min, adjust When the pH reaches 4.6, add pullulanase and react in a constant temperature water bath at 58°C for 8 hours; then precipitate the defatted starch solution with 1:4 absolute ethanol; remove the precipitated starch solution with a centrifuge The supernatant was obtained as a precipitate. Then wash with water 2-3 times. Freeze-drying with a lyophilizer to obtain short amylopectin; incubating the obtained short amylose at a medium temperature of 50° C. for 24 hours, and centrifuging to remove the su...

Embodiment 2

[0075] A process for preparing nano-starch by enzymatically hydrolyzing short amylose starch and self-assembly at medium temperature. The preparation method is as follows: Weigh 10 g of waxy corn starch after defatting, add 100 ml of distilled water, and prepare a 10% starch milk solution; buffer with citric acid After adjusting the pH of the starch solution to 4.6, heat the starch solution in a boiling water bath for 30 minutes, adjust the pH to 4.6, add pullulanase, and react for 8 hours in a constant temperature water bath at 58°C; then degrease the starch solution with 1: 4 of absolute ethanol precipitation; the precipitated starch solution was centrifuged with a centrifuge to remove the supernatant to obtain a precipitate. Then wash with water 2-3 times. Freeze-drying with a lyophilizer to obtain short amylopectin; incubating the obtained short amylose at a medium temperature of 30° C. for 12 hours, and centrifuging to remove the supernatant to obtain a precipitate. Quic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com