Modifying method of Y type molecular sieve

A molecular sieve and modification technology, applied in octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as long process and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to 1Al 2 o 3 : 15SiO 2 : 16Na 2 O: 320H 2 O molar ratio, 8.2g NaOH was added to 55ml deionized water, stirred to a clear solution, 3.0g sodium metaaluminate was added to the above solution, then 35.8g water glass (modulus 2.5) was added, and the stirring was continued at room temperature until All dissolved, and then aged at 30°C for 20 hours to obtain the directing agent.

[0028] Treat NaY-type molecular sieves in glycerin at 190°C for 2 hours. The mass mixing ratio of Y-type molecular sieves and glycerin is 1:5. Mix with polyacrylamide with a molecular weight of 10,000 at 70°C for 1 hour. The mass mixing ratio of Y-type molecular sieve to inorganic directing agent, water, polyquaternary ammonium urea-containing polymer and polyacrylamide is 1:0.6:5:0.1:0.1. Afterwards, it was treated in a closed reactor at 100°C for 12 hours, the mixture was filtered, washed with water, dried at 100°C for 3 hours, and then calcined at 550°C for 5 hours to obtain a mole...

Embodiment 2

[0038] According to 1Al 2 o 3 : 15SiO 2 : 16Na 2 O: 400H 2 O molar ratio, 8.2g NaOH was added to 58ml deionized water, stirred to a clear solution, 3.0g sodium metaaluminate was added to the above solution, then 35.8g water glass (modulus 2.5) was added, and the room temperature continued to stir until All dissolved, and then aged at 30°C for 20 hours to obtain the directing agent.

[0039] Treat NaY-type molecular sieves in glycerin at 200°C for 2 hours. The mass mixing ratio of Y-type molecular sieves and glycerin is 1:10. Mix with polyacrylamide with a molecular weight of 10,000 at 70°C for 1 hour. The mass mixing ratio of Y-type molecular sieve, inorganic guide agent, water, polyquaternary ammonium urea-containing polymer and polyacrylamide is 1:5:6:0.2:0.2 , and then treated in a closed reactor at 100°C for 12 hours, the mixture was filtered, washed with water, and dried at 100°C for 5 hours, and then calcined at 550°C for 5 hours to obtain a molecular sieve sample, ...

Embodiment 3

[0042] According to 1Al 2 o 3 : 15SiO 2 : 16.5Na 2 O: 320H 2 O molar ratio, 9.4g of water glass (modulus 3.3) was added to 6.9g of sodium metaaluminate solution, stirred to dissolve, and then aged at 45°C for 5 hours to obtain the directing agent. Treat NaY molecular sieves in glycerin at 200°C for 2 hours. The mass mixing ratio of Y molecular sieves and glycerin is 1:12. Ammonium chloride and polyacrylamide with a molecular weight of 10,000 were mixed at 80°C for 1 hour, and the mass mixing ratio of Y-type molecular sieve, inorganic guiding agent, water, polydimethyldiallylammonium chloride and polyacrylamide was 1:0.5 : 8: 0.15: 0.15, and then treated in a closed reactor at 110°C for 4 hours, filtered the mixture, washed with water, dried at 100°C for 5 hours, and then roasted at 550°C for 5 hours to obtain a molecular sieve sample. Recorded as AM-3. The structural parameters are shown in Table 1.

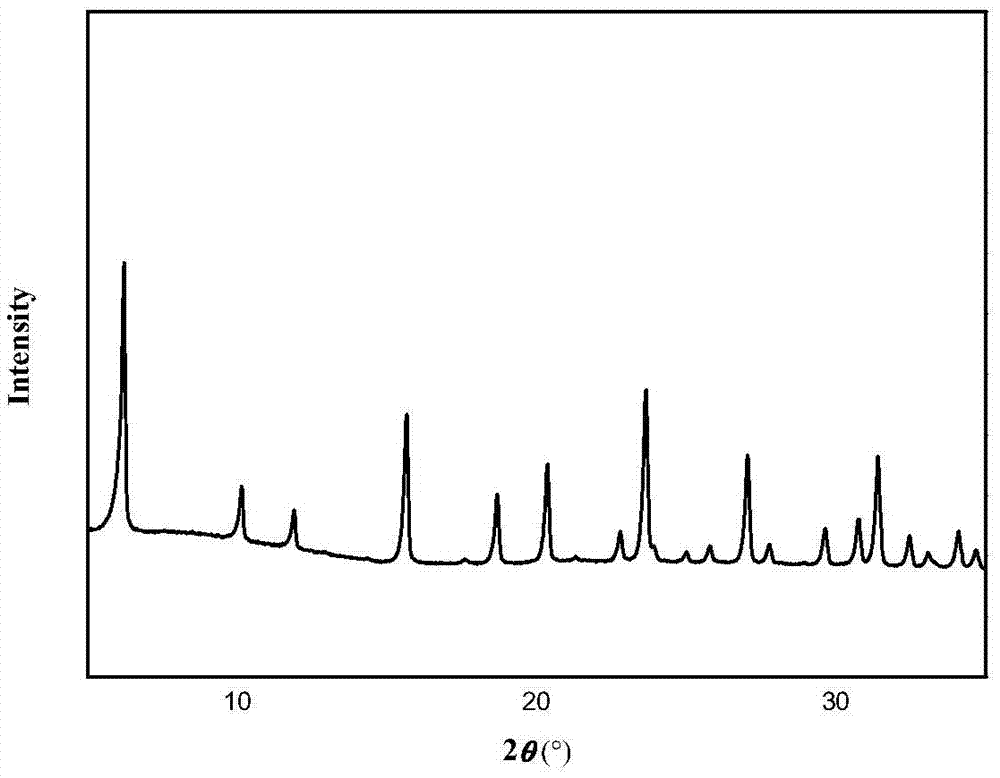

[0043] The characteristics of the XRD spectrum are the same as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com