A kind of double metal selenide material wrapped in graphene and its preparation method and application

A graphene-wrapped, bimetallic technology, applied in active material electrodes, electrochemical generators, structural parts, etc., can solve the problems of poor battery cycle and rate performance, poor cycle stability, slow diffusion kinetics, etc., and achieve cycle performance. Stable, uniform particle size, and the effect of alleviating structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

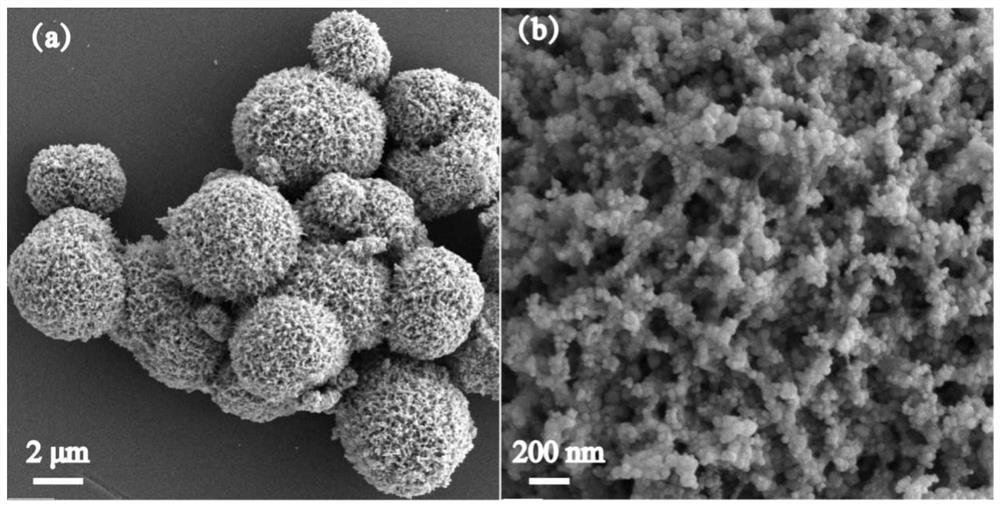

[0040] The present embodiment provides a preparation method of a graphene-wrapped bimetallic selenide material, comprising the following steps:

[0041] (1) 432 mg of nickel nitrate hexahydrate (Ni(NO) 3 ) 2 •6H 2 O) and 432 mg of cobalt nitrate hexahydrate (Co(NO) 3 ) 2 •6H 2 O), 300 mg trimesic acid and 3 g polyvinylpyrrolidone (PVP) were dissolved in 60 mL (1:1:1 volume ratio of ethanol, water, N,N-dimethylformamide) mixed solvent Stir for about 30 min to obtain a mixed solution, then transfer the mixed solution to a 100 mL autoclave, put the autoclave in an oven, and heat to 150 o C, incubated for 10 h, the final product was centrifuged at 10,000 rpm for 2 min, washed 5 times with water and ethanol, and finally dried in an oven at 80 °C for 12 h to obtain the reaction product NiCo-MOF-1;

[0042](2) 200 mg of NiCo-MOF-1 and 400 mg of selenium powder were mixed and ground evenly and then placed in a quartz magnetic boat for selenization and carbonization treatment. T...

Embodiment 2

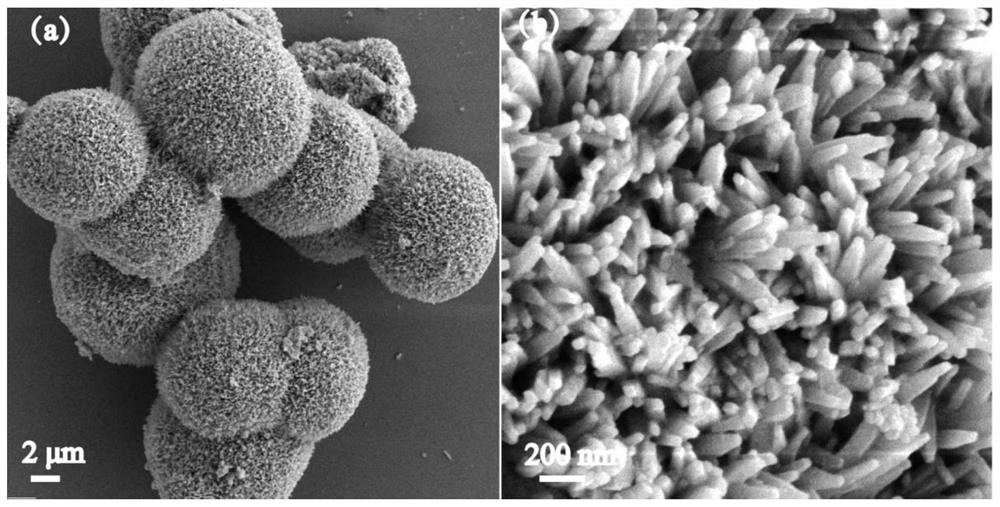

[0054] (1) 864 mg of nickel nitrate hexahydrate (Ni(NO 3 ) 2 •6H 2 O) and 432 mg of cobalt nitrate hexahydrate (Co(NO) 3 ) 2 •6H 2 O), 285 mg trimesic acid and 3 g polyvinylpyrrolidone (PVP) were dissolved in 60 mL (1:1:1 volume ratio of ethanol, water, N,N-dimethylformamide) mixed solvent Stir for about 30 min to obtain a mixed solution, then transfer the mixed solution to a 100 mL autoclave, put the autoclave into an oven, and heat it to 120 o C, incubated for 12 h, the final product was centrifuged at 10,000 rpm for 2 min, washed 5 times with water and ethanol, and finally dried in an oven at 80 °C for 12 h to obtain the reaction product NiCo-MOF-2;

[0055] (2) 200 mg of NiCo-MOF-2 and 600 mg of selenium powder were mixed and ground evenly, and then placed in a quartz magnetic boat for selenization and carbonization treatment. The condition is to start with 2 o C / min rate ramp up to 550 o C, hold for 12h under argon atmosphere, wait until cooled to room temperature...

Embodiment 3

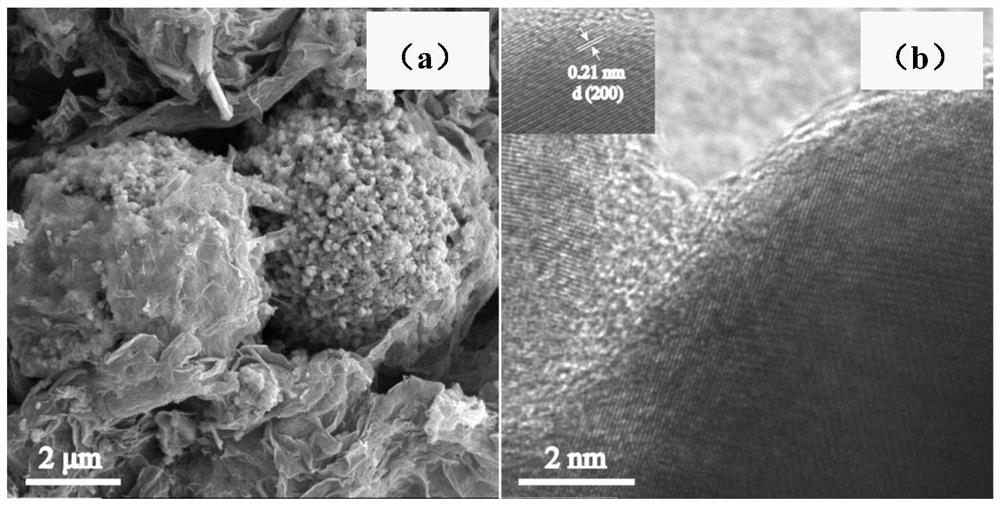

[0059] (1) 432 mg of nickel nitrate hexahydrate (Ni(NO) 3 ) 2 •6H 2 O) and 864 mg of cobalt nitrate hexahydrate (Co(NO) 3 ) 2 •6H 2 O), 522 mg trimesic acid and 3 g polyvinylpyrrolidone (PVP) were dissolved in 60 mL (1:1:1 volume ratio of ethanol, water, N,N-dimethylformamide) mixed solvent Stir for about 30 min to obtain a mixed solution, then transfer the mixed solution to a 100 mL autoclave, put the autoclave in an oven, and heat to 180 o C, incubated for 3 h, the final product was centrifuged at 10,000 rpm for 2 min, washed 5 times with water and ethanol, and finally dried in an oven at 80 °C for 12 h to obtain the reaction product NiCo-MOF-3;

[0060] (2) 200 mg NiCo-MOF-3 and 800 mg selenium powder were mixed and ground evenly, and then placed in a quartz magnetic boat for selenization and carbonization treatment. The condition is to start with 2 o C / min rate ramp up to 550 o C, hold for 12h under argon atmosphere, wait until cooled to room temperature to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com