High-efficiency water decomposition catalyst hollow cobalt phosphide and preparation method thereof

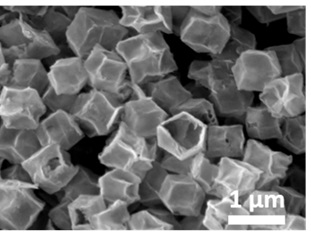

A technology of cobalt phosphide and catalyst, applied in the field of preparation of hollow cobalt phosphide, can solve the problems of low specific surface area, few active sites, and inability to achieve commercial use, and achieves large specific surface area, flat particle surface, excellent electrical The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing hollow cobalt phosphide as an efficient water splitting catalyst, the preparation steps are as follows:

[0037] S1. Prepare the required materials: Na 2 MoO 4 2H 2 O, Co (NO 3 ) 2·6H 2 O (98%), 2-methylimidazole (2-MIM, 95%), KOH (85%), methanol, ethanol, Nafion (5 wt%) and IrO 2 , the prepared chemicals were used as received without further purification, and the water used in the experiment was purified by filtration through ion-exchange membranes.

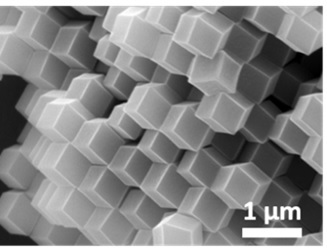

[0038] S2. Synthesis of ZIF-67: Take 30 mL of 20 mM Co(NO 3 ) 2 ·6H 2 O was added to the methanol solution and ultrasonically mixed, then 50 mL of 160 mM 2-MIM methanol solution was added; the mixture was reacted at room temperature for 24 hours without stirring, after the reaction, the precipitate was recovered by centrifugation and washed with excess methanol The precipitate was washed and dried in air at 60° C. to obtain ZIF-67.

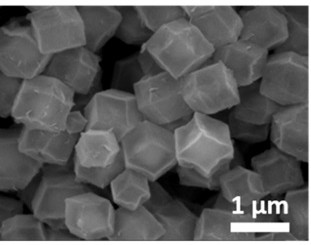

[0039] S3.Co(OH) 2 Synthesis of: Take 40mg of ZIF-67 pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com