Method for preparing hollow mesoporous silica nanosphere loaded propranolol hydrochloride composite system

A technology of propranolol hydrochloride and mesoporous silica is applied in the field of preparing hollow mesoporous silica nanospheres supporting propranolol hydrochloride composite system, and can solve the problems of difficult control, long preparation time, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

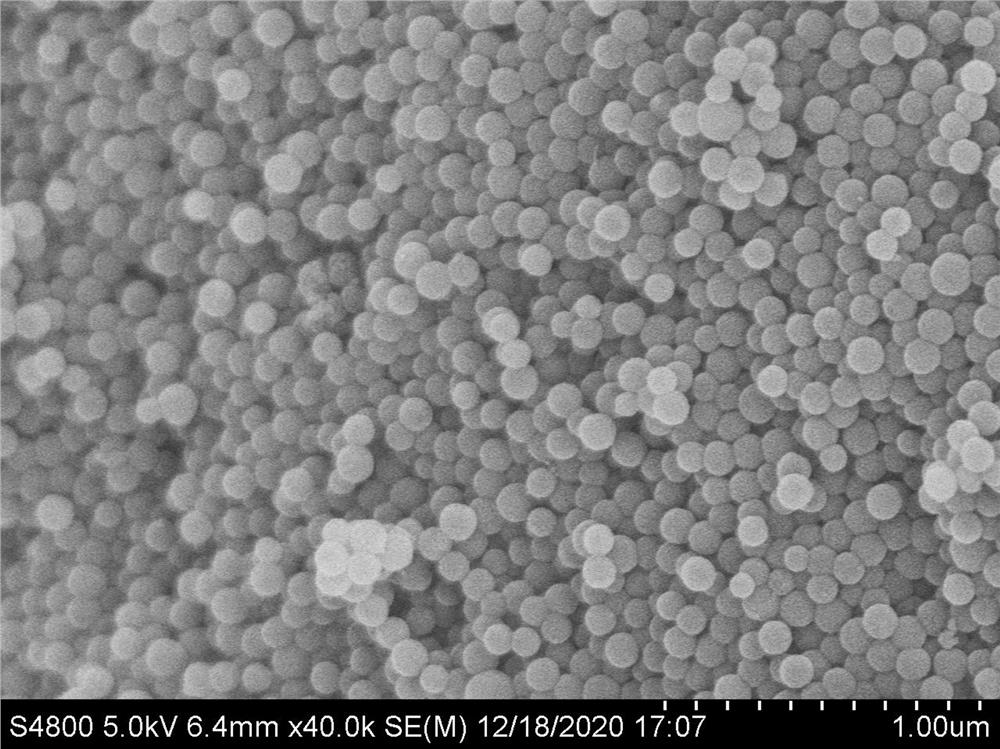

[0041] (1) Solid silica spheres (sSiO 2 ) preparation

[0042] Prepare solution A: Put 2mL of 28% concentrated ammonia water, 16.25mL of absolute ethanol and 24.75mL of deionized water into a 250mL three-neck flask, and place it in a constant temperature water bath at 24°C and 1100rpm magnetic stirring for 30min.

[0043] Prepare solution B: put 4.5mL tetraethyl orthosilicate and 45.5mL absolute ethanol into a 100mL beaker, seal it with plastic wrap, and ultrasonically dissolve it for 45min.

[0044] Quickly add B to A, reduce the stirring speed to 360-400rpm after 1min, and react in a constant temperature water bath at 24°C for 2h, then centrifuge the product and wash it with ethanol (three times, centrifuge speed 8000rpm, time 5min), and then put it in a vacuum dryer Store in airtight after drying.

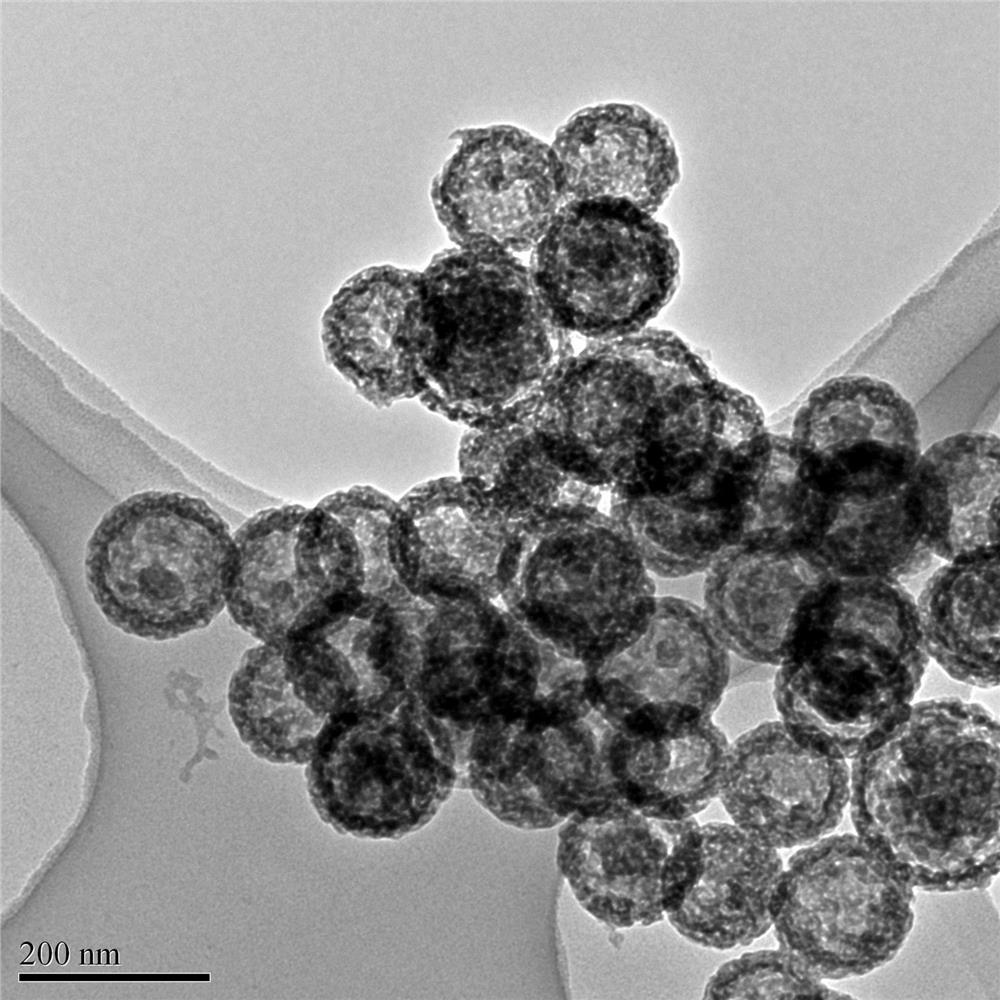

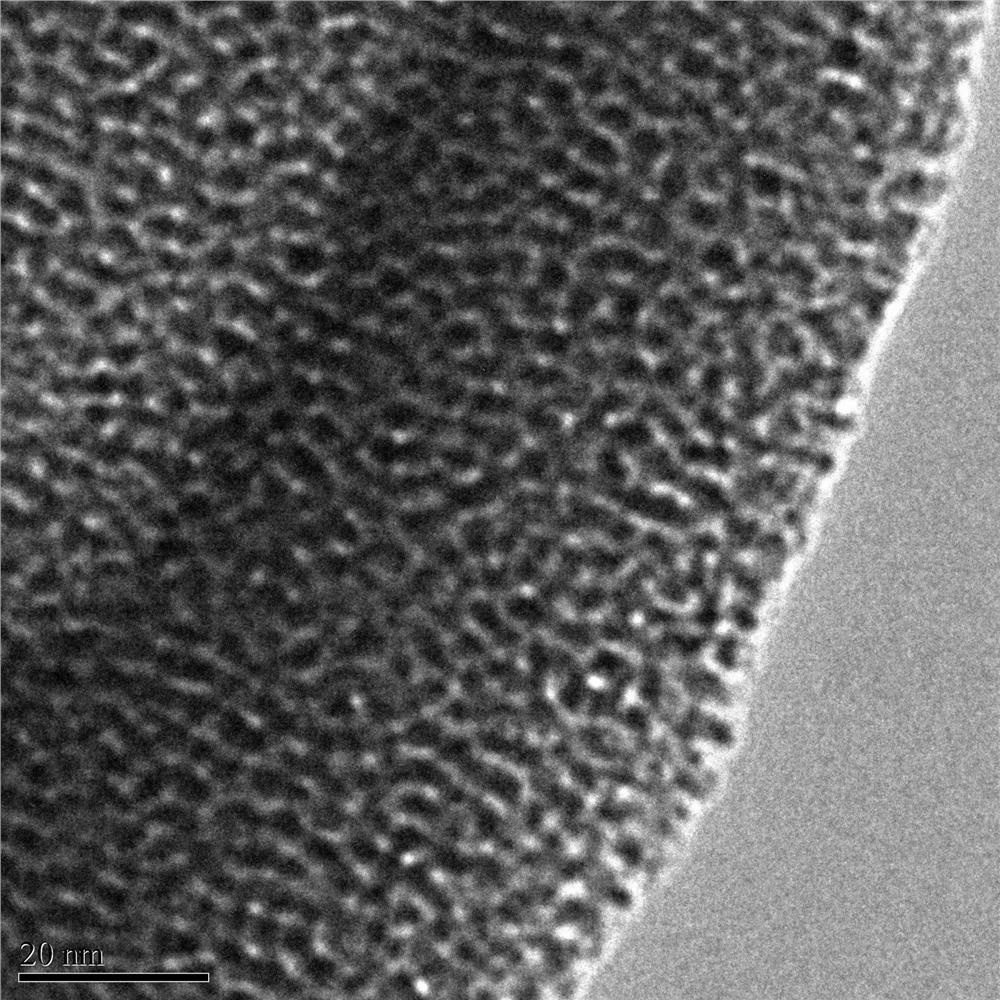

[0045] (2) Preparation of hollow mesoporous silica nanospheres (HMSS)

[0046] 50 mg of prepared sSiO 2 After ultrasonic treatment for 15 min, it was uniformly dispersed in ...

Embodiment 2

[0055] (1) Solid silica spheres (sSiO 2 ) preparation

[0056] With embodiment 1.

[0057] (2) Preparation of hollow mesoporous silica nanospheres (HMSS)

[0058] 50 mg of prepared sSiO 2 After ultrasonic treatment for 15 min, it was uniformly dispersed in 9 mL of deionized water, and then 1 mL of cetyltrimethylammonium bromide aqueous solution (12.5 mg / mL) was added and stirred at room temperature for 30 min. Anhydrous sodium carbonate (212 mg) was added to the mixture, and after stirring at 35 °C, 1500 rpm for 24 h, the product was collected by centrifugation and washed with deionized water and ethanol and dried. The dried solid was heated to 550 °C in air at a rate of 1.5 °C / min and kept for 6 h to obtain hollow mesoporous silica nanospheres (HMSS).

[0059] (3) Preparation of propranolol hydrochloride solution

[0060] Weigh 161 mg of propranolol hydrochloride and dissolve it in 7 mL of methanol to obtain a solution with a concentration of 23 mg / mL, and weigh 500 mg o...

Embodiment 3

[0067] (1) Solid silica spheres (sSiO 2 ) preparation

[0068] With embodiment 1.

[0069] (2) Preparation of hollow mesoporous silica nanospheres (HMSS)

[0070] With embodiment 1.

[0071] (3) Preparation of propranolol hydrochloride solution

[0072] Weigh 231 mg of propranolol hydrochloride and dissolve it in 7 mL of methanol to obtain a solution with a concentration of 33 mg / mL, and weigh 500 mg of hollow mesoporous silica nanospheres.

[0073] (4) drug load

[0074] Slowly add the propranolol hydrochloride solution to the hollow mesoporous silica nanospheres, drop 0.6mL each time to form a viscous paste and there is no clear liquid in the upper layer, put the paste in a constant temperature blast drying oven Dry at 50°C, then continue to add 0.6mL propranolol hydrochloride solution dropwise until a paste is formed, dry, and repeat the operation until all the propranolol hydrochloride solution is added dropwise.

[0075] (5) washing

[0076] The composite system ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com