A kind of preparation method of lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, nanotechnology for materials and surface science, etc., can solve the problem of difficulty in forming a dense coating layer, unsatisfactory power performance, cumbersome operation, etc. problems, to achieve the effect of regulating the kernel size, mild conditions, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

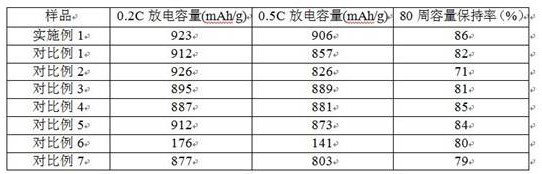

Examples

preparation example Construction

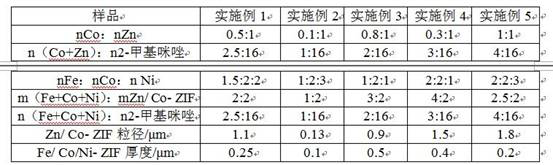

[0031] The present invention provides a kind of preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0032] S1. Preparation of zinc / cobalt bimetallic zeolite imidazolate framework material Zn / Co-ZIF;

[0033] Wherein, the substance ratio of Co and Zn is (0.1~1):1;

[0034] S2. In a protective gas atmosphere, uniformly disperse ferrous salt, cobalt salt, nickel salt, 2-methylimidazole and the Zn / Co-ZIF prepared in S1 in the first organic solvent respectively to obtain the corresponding organic solution;

[0035] S3. In a protective gas atmosphere, mix the ferrous salt organic solution, cobalt salt organic solution and nickel salt organic solution with the Zn / Co-ZIF organic solution, and then add the 2-methylimidazole organic solution, After stirring evenly, let stand, filter, wash and dry to obtain Zn / Co-ZIF@Fe / Co / Ni-ZIF with core-shell structure;

[0036] Wherein, the molar ratio of the ferrous salt, the cobalt salt and the...

Embodiment 1

[0043] This embodiment provides a preparation method of lithium ion battery negative electrode material, comprising the following steps:

[0044] S1, preparation of zinc / cobalt bimetallic zeolite imidazolate framework material Zn / Co-ZIF; wherein the molar ratio of Co to Zn is 0.5:1;

[0045] The specific process is:

[0046] 148.74mg of zinc nitrate is dissolved in methanol to obtain the methanol solution of zinc nitrate with a concentration of 0.025mol / L, and 32.46mg of cobalt chloride is dissolved in methanol to obtain a concentration of 0.025mol / L. Solution, dissolve 4.8mol of 2-methylimidazole in methanol to obtain a methanol solution of 2-methylimidazole with a substance concentration of 1.5mol / L, then mix the three, stir evenly, and then let stand for 15h to obtain blue The turbid liquid was filtered by suction and dried at 80°C to obtain a blue powder, namely Zn / Co-ZIF;

[0047] Wherein, the ratio of the sum of the amount of substances of the zinc salt and the cobalt ...

Embodiment 2

[0055] This embodiment provides a preparation method of lithium ion battery negative electrode material, comprising the following steps:

[0056] S1, preparation of zinc / cobalt bimetallic zeolite imidazolate framework material Zn / Co-ZIF; wherein, the molar ratio of Co to Zn is 0.1:1;

[0057] The specific process is:

[0058] 340.75mg of zinc chloride is dissolved in ethanol to obtain the ethanol solution of zinc chloride whose concentration of substance is 0.5mol / L, and 72.75mg of cobalt nitrate is dissolved in ethanol to obtain the concentration of substance in ethanol of cobalt nitrate Solution, dissolve 44mol of 2-methylimidazole in ethanol to obtain an ethanol solution of 2-methylimidazole with a substance concentration of 2.8mol / L, then mix the three, stir evenly, and then let it stand for 20h to obtain azure blue The turbid liquid was suction filtered and dried at 60°C to obtain a blue powder, namely Zn / Co-ZIF;

[0059] Wherein, the ratio of the sum of the amount of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com