A kind of preparation method of hollow co-fe LDH material

A hollow, fe-mofs technology, applied in chemical instruments and methods, cobalt compounds, inorganic chemistry, etc., to achieve the effect of good catalysis, good application prospects, and multiple electrochemical active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

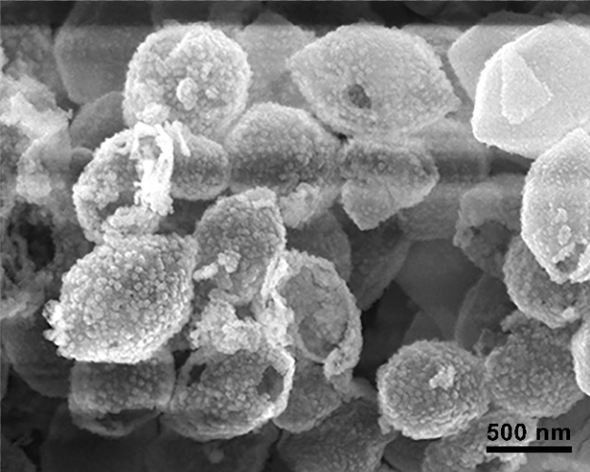

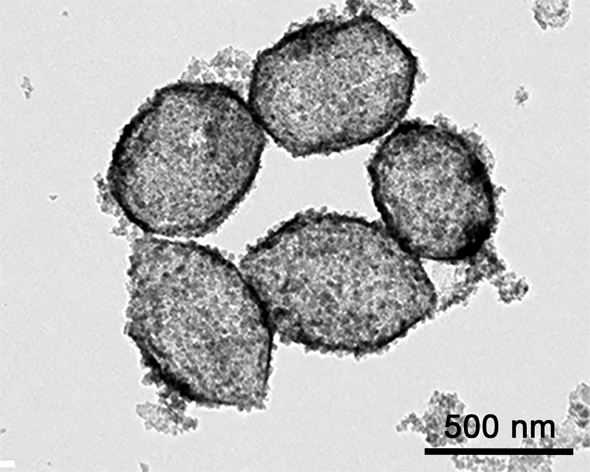

[0027] A preparation method of a hollow Co-Fe LDH material, comprising the following steps:

[0028] Step 1. Stir and mix the iron source, fumaric acid and N,N-dimethylformamide solution to obtain a mixed solution; transfer the mixed solution to an autoclave, heat up to 80~100°C, and react for 2~5 h, cooled to room temperature, centrifuged to collect the precipitate to obtain Fe-MOFs material;

[0029] In step 2, the Fe-MOFs obtained in step 1 are fully washed with DMF solution, and dried at a temperature of 75-85 °C for 12-24 h, for use;

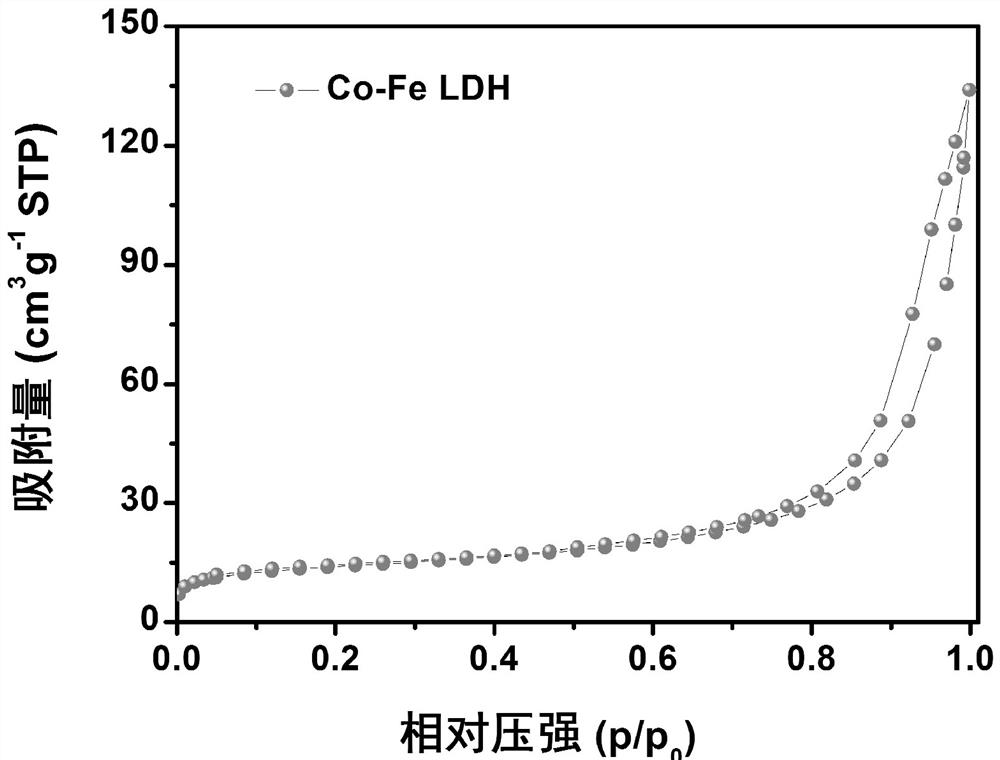

[0030] Step 3, ultrasonically dispersing the Fe-MOFs material obtained in step 2 in absolute ethanol to obtain solution A, dissolving cobalt source and urea with a molar ratio of 2~3:1 in deionized water to obtain solution B. Mix A and solution B evenly, transfer to a sealed container, heat in a water bath and cool to room temperature, wash the obtained precipitate with deionized water and absolute ethanol, and dry it at a temperature of 5...

Embodiment 2

[0038] A preparation method of a hollow Co-Fe LDH material, comprising the following steps:

[0039] Step 1, preparing the precursor Fe-MOFs material by solvothermal method, the specific steps are as follows: stirring and mixing iron source, fumaric acid and N,N-dimethylformamide solution, iron source and fumaric acid The molar ratio of acid is 3:4~5 to obtain a mixed solution; the mixed solution is transferred to an autoclave, heated to 100 °C, reacted for 3 h, cooled to room temperature, centrifuged, and the precipitate is collected to obtain Fe-MOFs material;

[0040] In step 2, the Fe-MOFs obtained in step 1 are fully washed with DMF solution, and dried for 12 h at a temperature of 70-80 °C, for use;

[0041] Step 3, ultrasonically dispersing the Fe-MOFs material obtained in step 2 in absolute ethanol to obtain solution A, dissolving cobalt source and urea with a molar ratio of 2~3:1 in deionized water to obtain solution B. Mix A and solution B evenly, and the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com