Method for restoring sticky expansion of aerobic granular sludge

An aerobic granular sludge and viscous technology, used in chemical instruments and methods, water/sludge/sewage treatment, granular microbial carrier treatment, etc., can solve problems such as swelling and instability, and achieve smooth surface and regular shape. , the effect of good sedimentation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

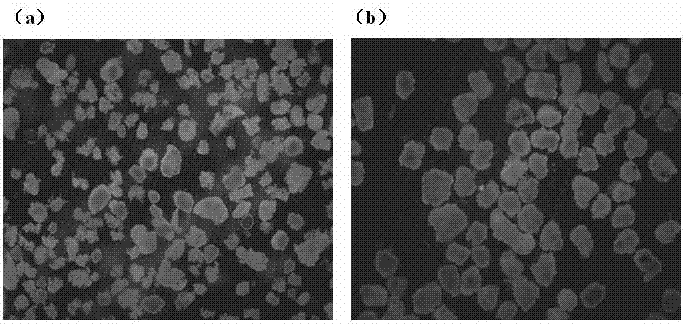

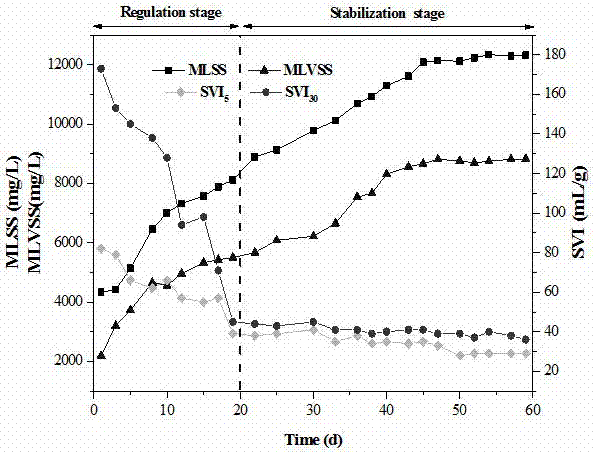

[0018] (1) Granular sludge with viscous expansion: the reactor influent COD is 1000 mg / L, and the organic load is 3.0 kg COD / m 3 d, COD:N:P=100:7:1, pH=7.2, CaCl 2 100 mg / L, MgSO 4 30 mg / L, FeSO 4 3 mg / L, the concentration of trace elements added are: H 3 BO 3 0.05mg / L, CuSO 4 ·5H 2 O 0.05mg / L, ZnSO 4 ·7H 2 O 0.05mg / L, AlCl 3 ·6H 2 O 0.09 mg / L, CoCl 2 6H 2 O 0.05mg / L, MnSO 4 ·H 2 O 0.05mg / L, (NH 4 ) 2 Mo 7 o 24 0.05 mg / L, NiCl 2 ·6H 2 O 0.09 mg / L. When the viscous swelling problem occurred, the average particle size of the granular sludge was 1.2 mm, the SVI was 82 mL / g, and the sludge concentration was 4.33 g SS / L. The surface of the granular sludge was rough and the structure was loose under the microscope, such as figure 2 (a) shown.

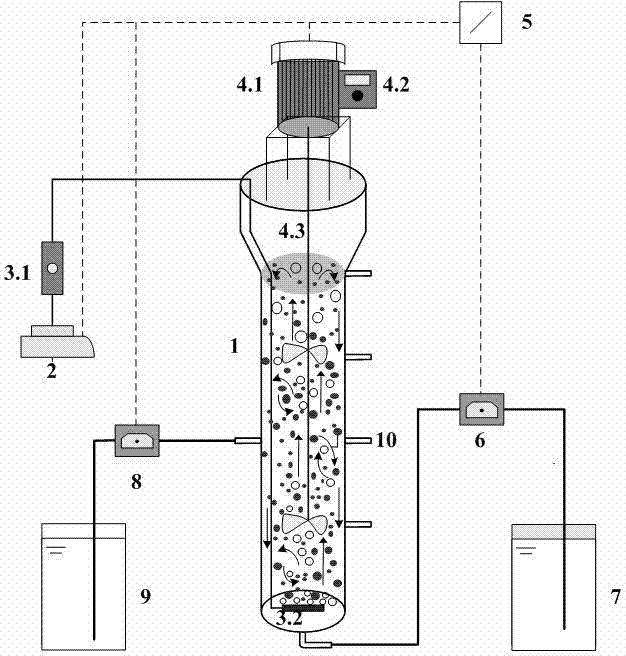

[0019] (2) Bioreactor: The reactor is made of plexiglass, with a height of 70cm, an inner diameter of 10cm, and an effective volume of 4L. It adopts the sequence batch operation mode, and the water inlet, stirring, a...

Embodiment 2

[0023] (1) Granular sludge with viscous expansion: SBR reactor influent COD is about 500mg / L, ammonia nitrogen is 30-50 mg / L, and KH is added 2 PO 4 and K 2 HPO 4 ·3H 2 O is 34 mg / L and 45 mg / L respectively, the control system pH=7.3, CaCl 2 , MgSO 4 , FeSO 4Concentrations were 80 mg / L, 20 mg / L, 6 mg / L, and the dosage of other trace elements were: H 3 BO 3 0.1 mg / L, CuSO 4 ·5H 2 O 0.1 mg / L, ZnSO 4 ·7H 2 O 0.1 mg / L, AlCl 3 6H 2 O 0.18 mg / L, CoCl 2 6H 2 O 0.1 mg / L, MnSO 4 ·H 2 O 0.1 mg / L, (NH 4 ) 2 Mo 7 o 24 0.1 mg / L, NiCl 2 ·6H 2 O 0.18 mg / L. The problem of viscous swelling occurred during the operation. The average particle size of the granular sludge was 0.9 mm, the SVI increased to 90 mL / g, and the sludge concentration decreased to 3.6 g SS / L (of which 1.8 g SS / L was the control group). The turbidity increases, presenting cloudy milky white. Granular sludge under the microscope Figure 4 (a) shown.

[0024] (2) Granular sludge reactor: The react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com