Dual frequency grating measuring device

A measuring device and dual-frequency grating technology, which is applied in the field of dual-frequency grating measuring devices, can solve problems such as difficult installation and adjustment of gratings and reading heads, inconvenient installation and use, and failure of measurement systems, achieving high repeatable measurement accuracy and simple structure , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

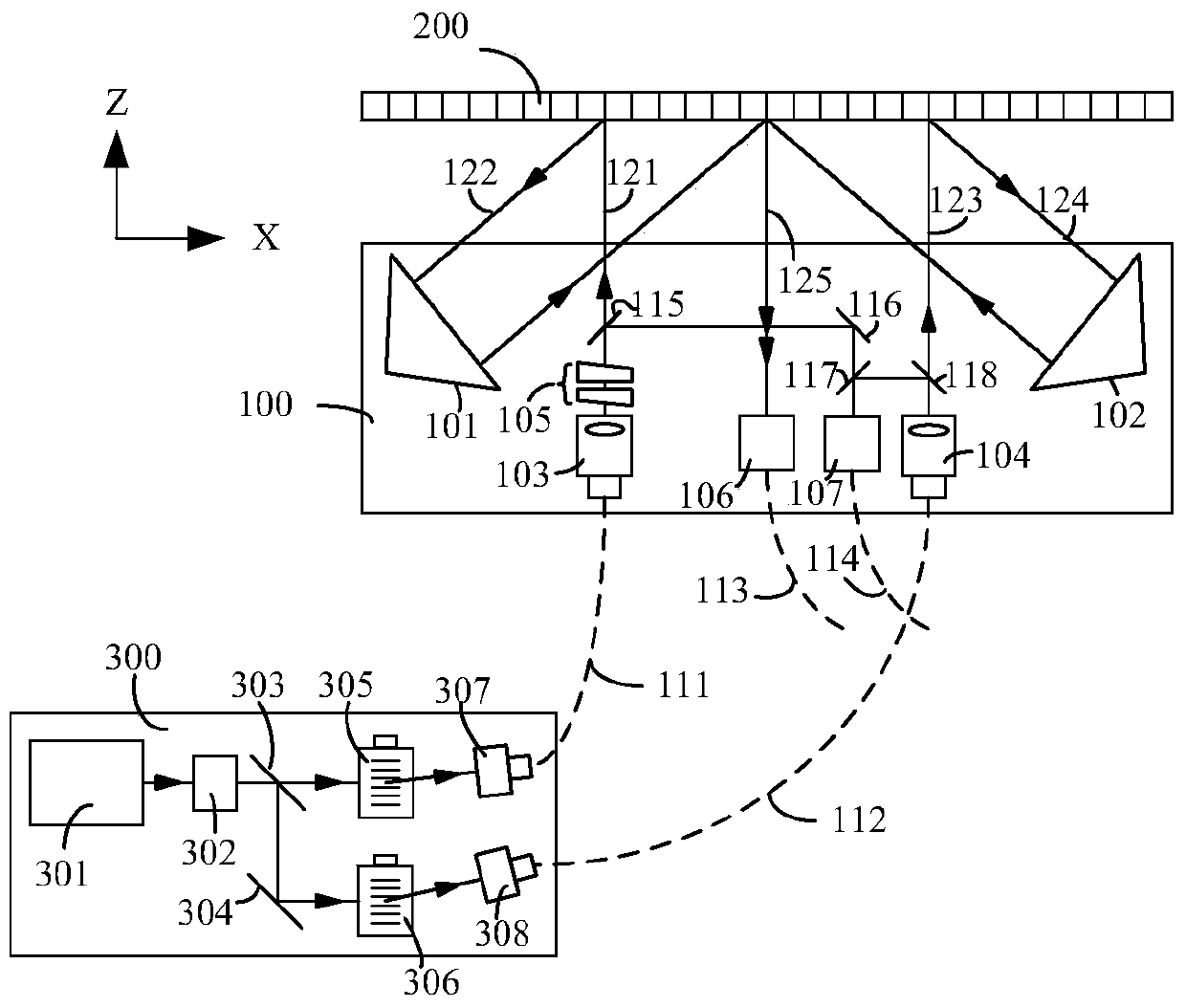

[0031] refer to figure 1 , the dual-frequency grating measurement device of the present invention includes: a grating measurement probe 100 , a grating 200 and a light source module 300 . Wherein, the light source module 300 is used to generate two beams of different frequencies, and transmit the two beams to the grating measuring probe 100 through an optical fiber, and the grating measuring probe 100 is provided with two sets of optical paths for respectively The two beams are received, and the two beams are split, so that one part is transmitted to the detector through the optical fiber, and the other part is projected on the surface of the grating for diffraction and then transmitted to the detector through the optical fiber.

[0032] Continue to refer to figure 1 , the light source module 300 includes a laser 301 , an isolator 302 , a beam splitter, a frequency shifter and a coupler, and the beam splitter includes a beam splitter 303 and a reflector 304 .

[0033] The la...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that in Embodiment 1 a one-dimensional reflective grating is used, while in this embodiment a two-dimensional reflective grating is used.

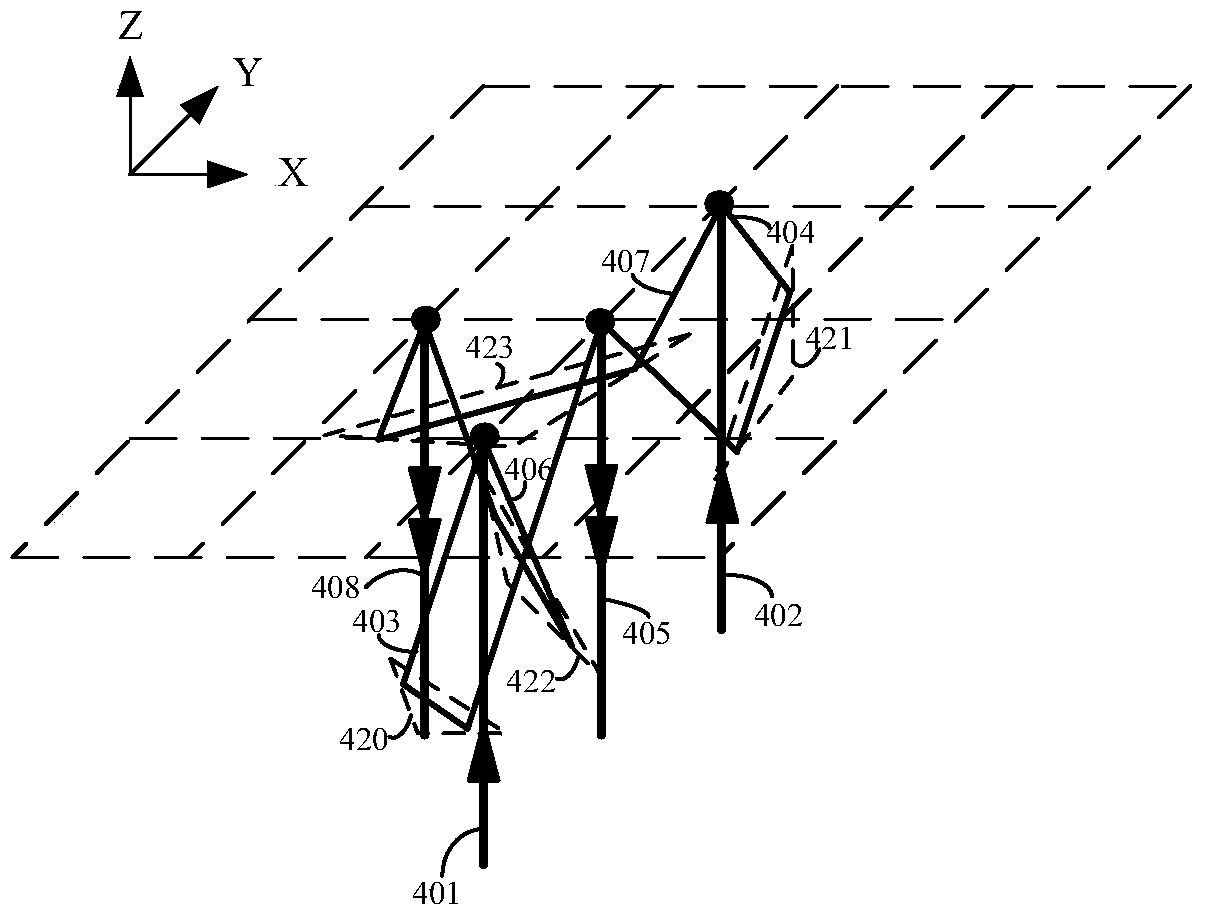

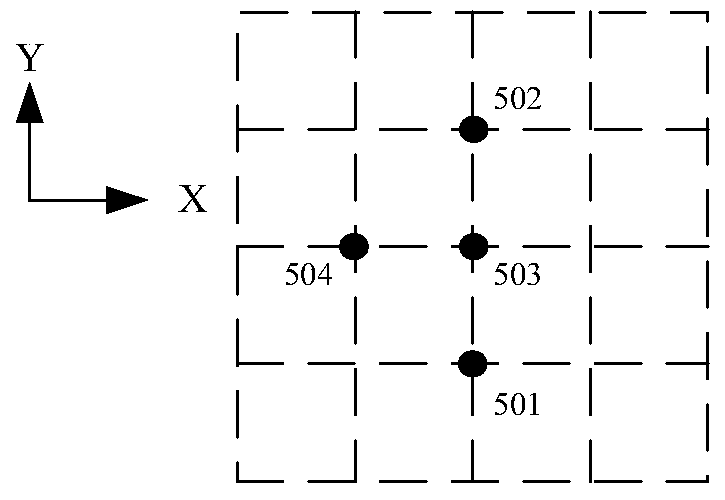

[0053] The layout of the 2D probe is as figure 2 shown. The incident beam 401 with a frequency of Δf1 and the incident beam 402 with a frequency of Δf2 undergo two-dimensional diffraction on the two-dimensional grating, the diffracted beam 403 is of Δf1 (0, -1) order, and the diffracted beam 404 is of Δf2 (0, +1) order , the diffracted beam 406 is of order Δf1(+1,0), and the diffracted beam 407 is of order Δf2(-1,0). Four corner cube prisms 420, 421, 422 and 423 are used to retroreflect the beam, so that the beam 403 and the beam 404 are retroreflected at the same point and exit along the direction of the beam 405. Through the signal of the beam 405, the two-dimensional grating can be detected in the Y direction The displacement of the light beam 406 and the light beam 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com