Photoetching system capable of detecting mask curvature and detection method

A lithography system and detection method technology, applied in microlithography exposure equipment, optics, optomechanical equipment and other directions, can solve the problem of object image distance calculation error, vertical positioning error, only the edge of the mask can be fixed, etc. Achieve the effect of ensuring freedom of movement, simple structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

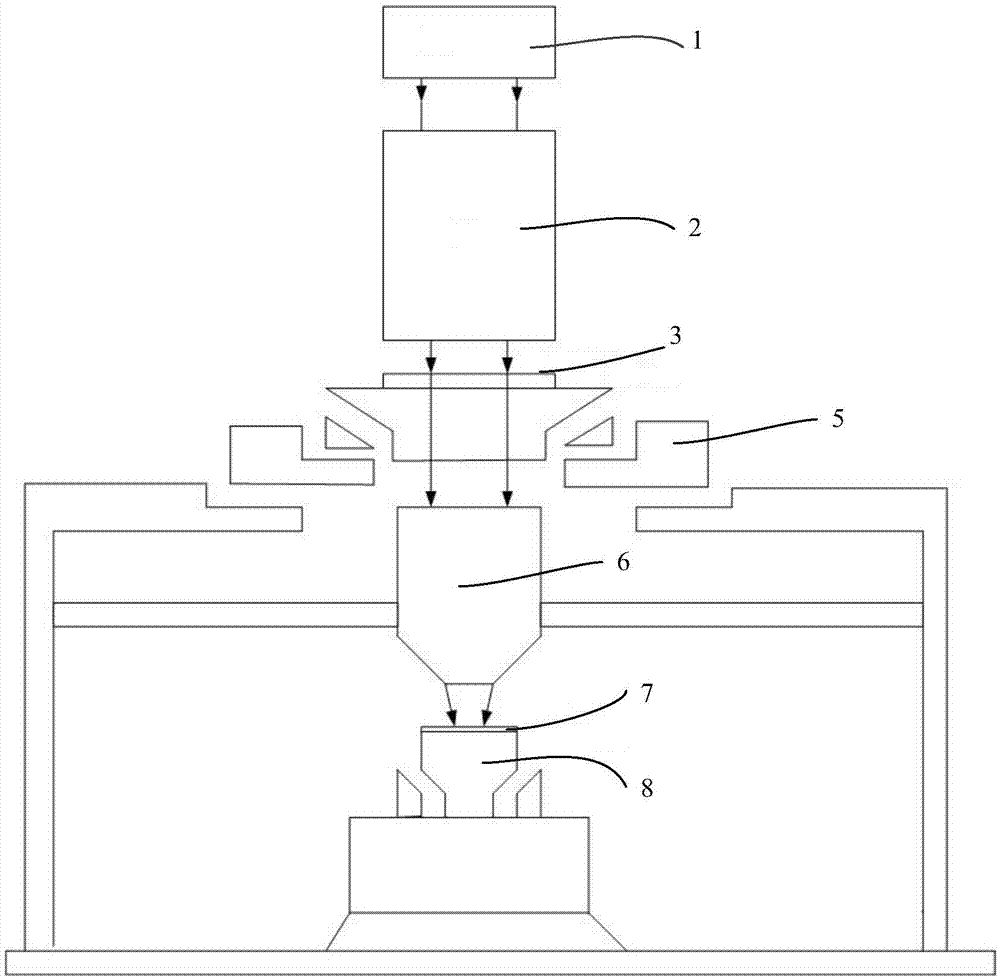

[0058] Please refer to figure 1 , the present invention provides a photolithography system capable of detecting the curvature of a mask, which sequentially includes

[0059] An illuminating light source 1 for emitting illuminating light, generally ultraviolet light;

[0060] An illumination assembly 2, which is used to form the illumination light into parallel light, so that the adjusted illumination from the illumination assembly 2 is uniform, so that the intensity of illumination received by the mask 3 is the same;

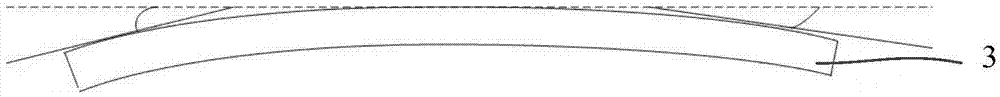

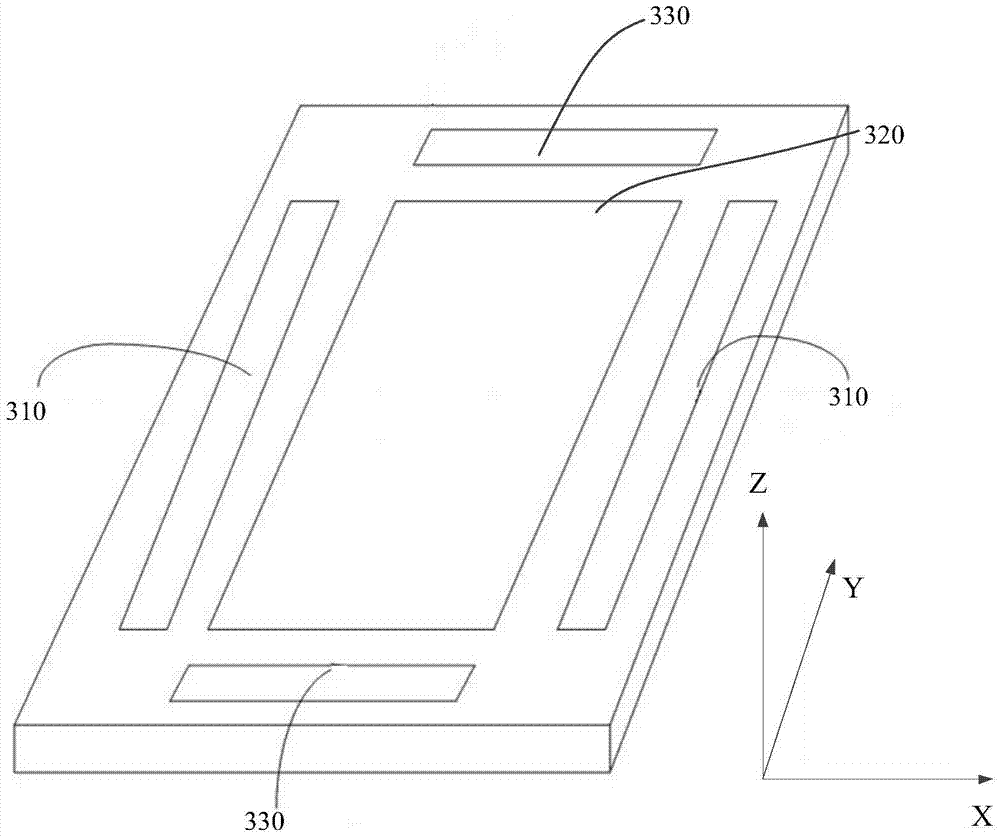

[0061] A mask 3, the mask 3 is provided with several measurement marks for measuring the curvature of the mask;

[0062] The sensor 4 is used to read the position information of the measurement mark, and the position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com