Tremor stability domain lobe graph modeling method based on ball-end milling cutter and workpiece contact area

A ball-end milling cutter and contact area technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of inability to accurately determine the number of teeth involved in cutting, the actual cutting position, and reduce the accuracy of lobe diagrams , Affecting the scope of application of leaflet diagrams and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0106] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0107] A method for constructing a lobe map of a chatter stable domain during machining of a ball end milling cutter, comprising the following steps:

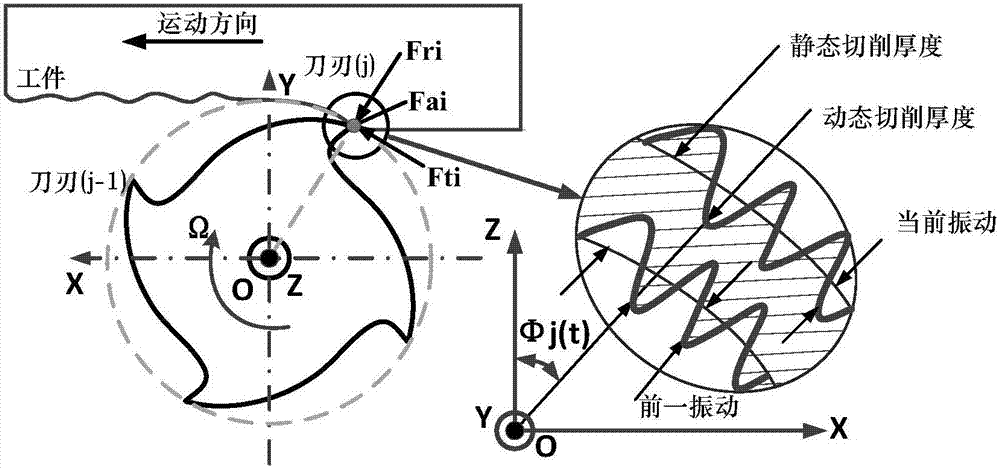

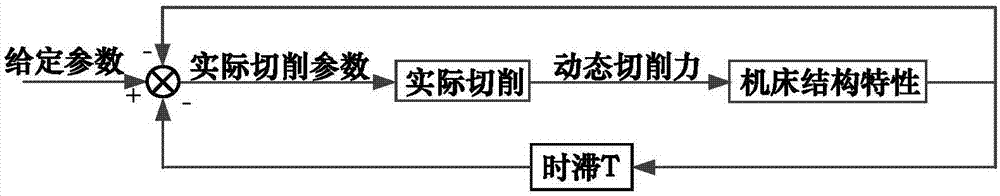

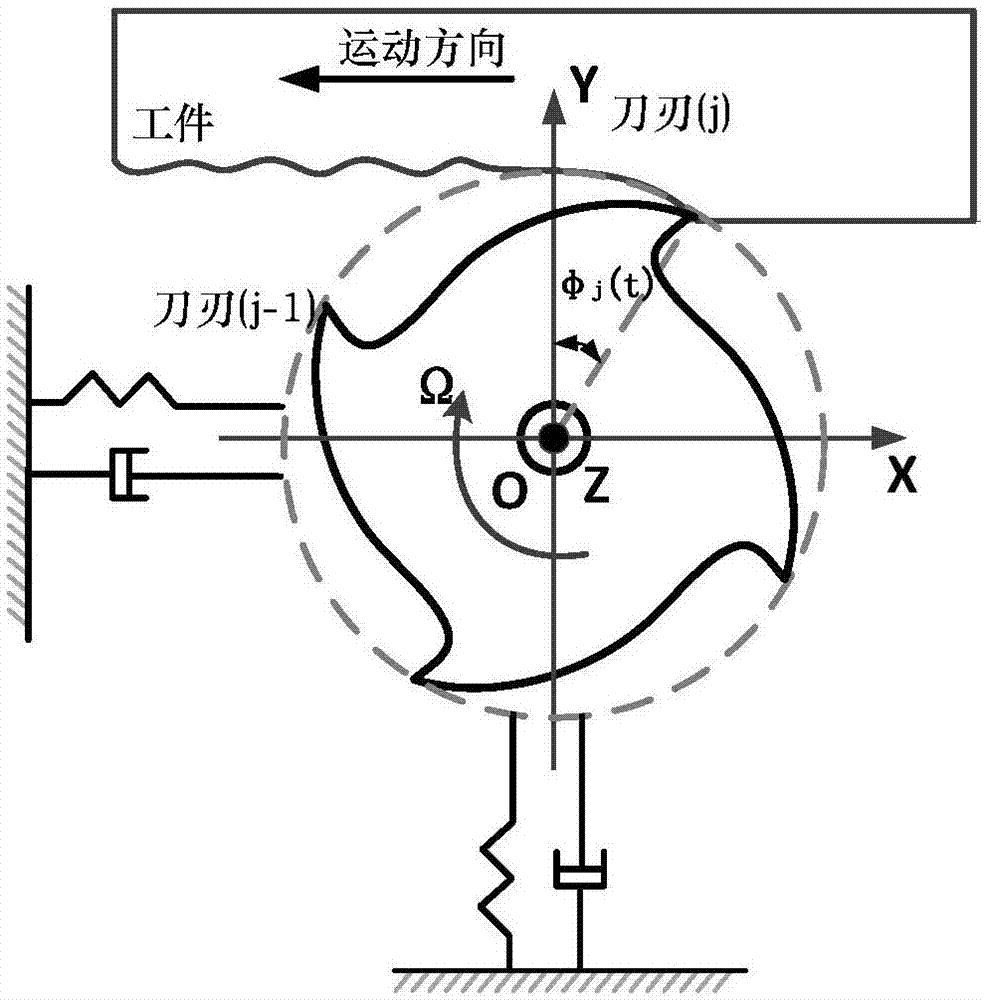

[0108] Step 1, establish ball end milling cutter tool-workpiece dynamics equation

[0109] Such as image 3 As shown, the ball milling cutter tool-workpiece system is simplified to a two-degree-of-freedom system, and only the tool vibration factors in the feed direction x and normal y directions are considered, and the following dynamic equations are established:

[0110]

[0111] Among them, m tx is the modal mass of the tool system in the x direction, m ty is the modal mass of the tool system in the x direction; ξ x is the damping coefficient of the tool system in the x direction, ξ y is the damping coefficient of the tool system in the y direction; ω nx T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com