Laser annealing device and annealing method thereof

A laser annealing and laser technology, applied in the direction of laser devices, lasers, laser welding equipment, etc., can solve the problems of reducing the effect and stability of silicon wafer lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in detail below in conjunction with accompanying drawing:

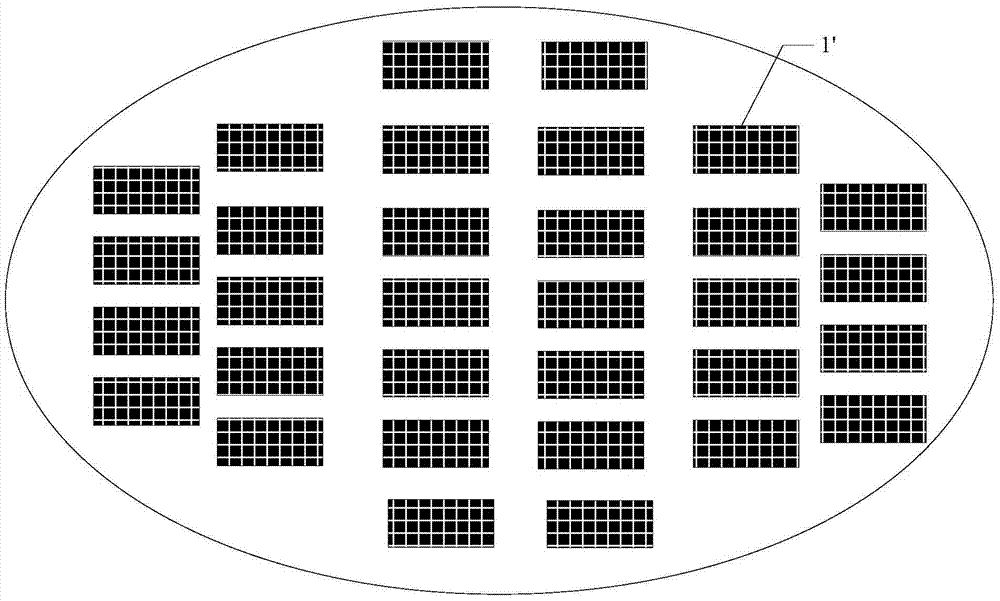

[0057] like Figure 4 As shown, the present invention provides a kind of laser annealing device, is used for carrying out laser annealing to the silicon chip 1 on the slide stage 2, comprises:

[0058] The laser light source system 3 includes at least two lasers 31 that output laser beams that are irradiated on the surface of the silicon wafer 1 for annealing. The power of the laser beams is adjustable, and the laser wavelengths output by each laser 31 are different, and each The power of the lasers 31 can be adjusted independently.

[0059] The laser adjustment system 4 is connected with the laser light source system 3 and is located above the silicon wafer 1, including at least two laser adjusters 41 corresponding to the lasers 31 one by one, monitoring the power of the corresponding laser beam and the spot The position of the surface of the silicon wafer 1 adjusts the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com