Crude separation mechanism for liquid dung

A rough separation and manure-water technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of organic matter loss, low separation efficiency, waste of organic matter, etc., and achieve the effect of reducing the loss of organic matter components, reducing maintenance costs, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

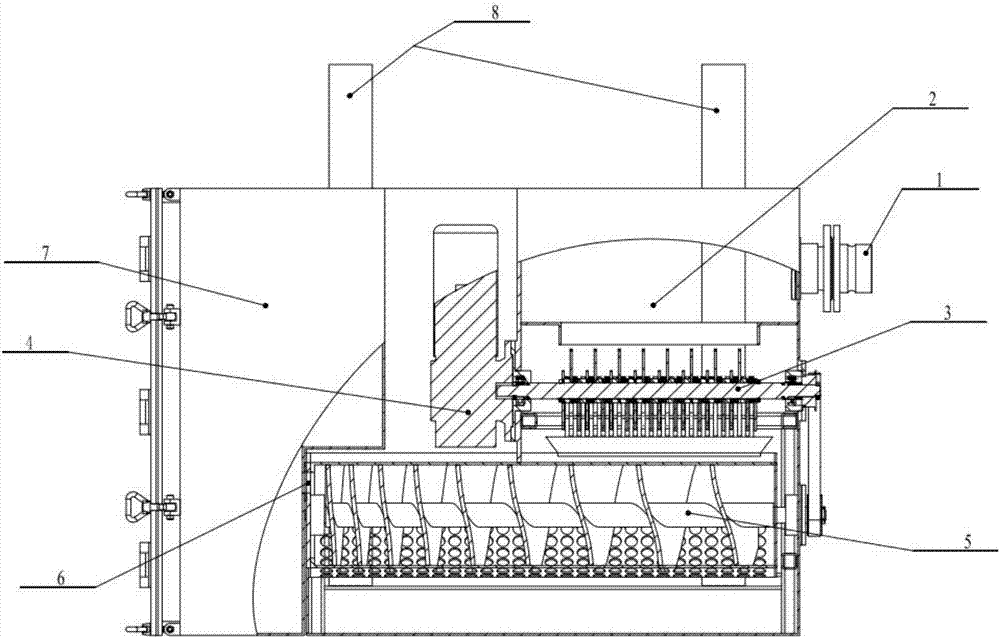

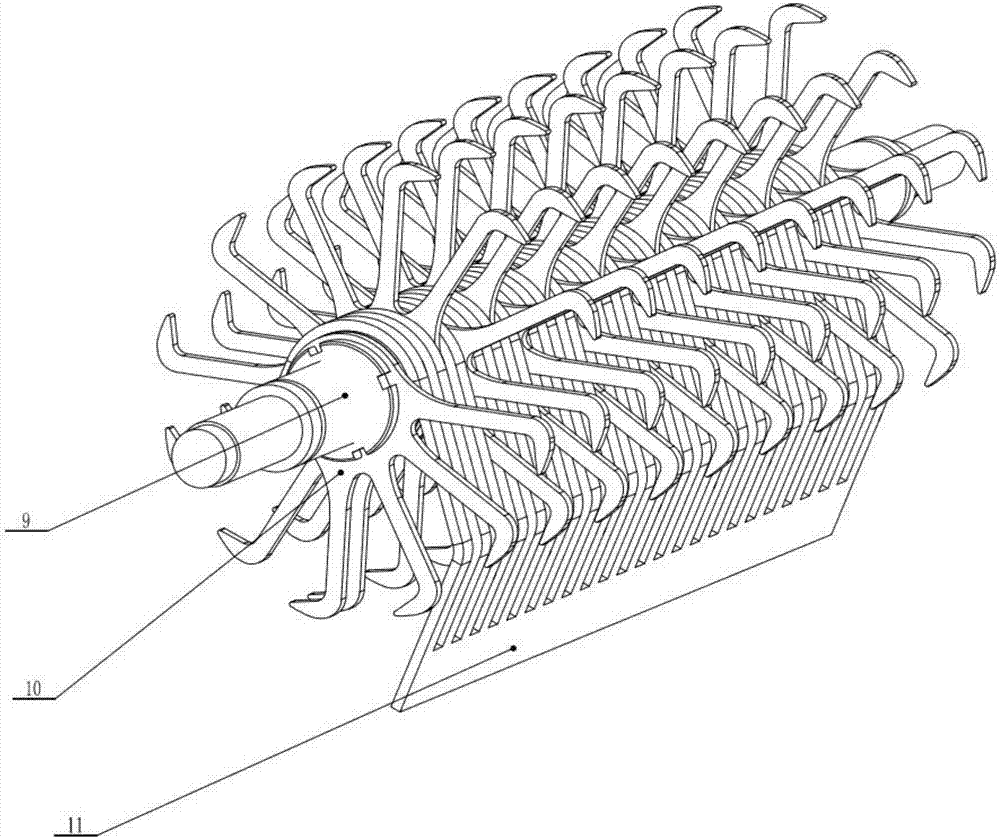

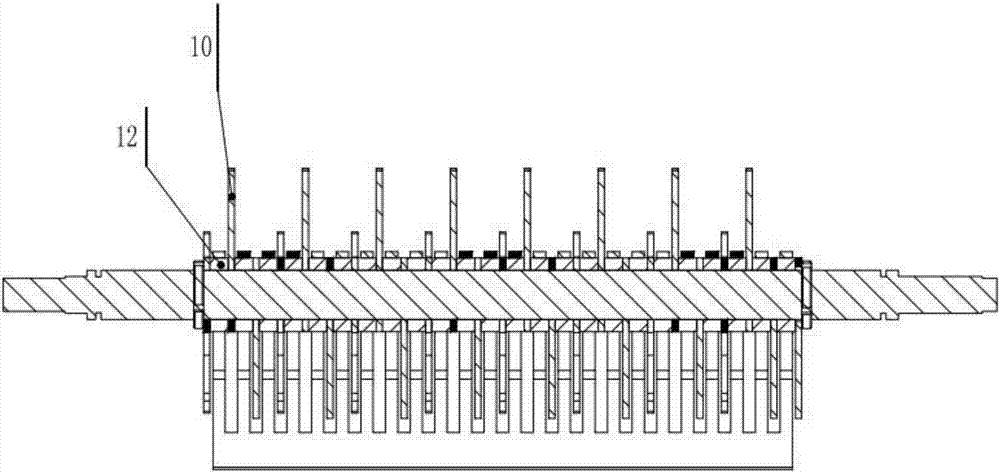

[0018] like Figure 1-4 Shown: a coarse separation mechanism for feces and water, its structure includes: mixed material inlet 1, mixed material bin 2, coarse material separation device 3, motor 4, coarse material extrusion device 5, coarse material outlet 6, coarse material storage box 7. The thinner material outlet 8, the rake shaft 9, the rake active teeth 10, the cleaning comb plate 11, the rake adjustment piece 12; the manure enters the mixing bin 2 through the mixing inlet 1, and the mixing bin 2 is provided with a Rectangular outlet, the rectangular outlet overlaps with the rake part of the coarse material separation device 3, the mixed material falls on the rake through the rectangular outlet, the rake is formed by the active teeth 10 of the staggered rake in series, each adjacent tooth There is a gap between the rake driving teeth 10, and the thinner part of the mixture passes through the gap. The size of the gap is adjusted by the tooth rake adjustment piece 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com