Lithium ion battery positive electrode plate and lithium ion battery negative electrode plate, making methods thereof, roll core, and lithium ion battery

A lithium ion battery, positive and negative plate technology, applied in electrode manufacturing, battery electrodes, electrode current collector coating, etc., can solve the problem of the inner layer plate easily broken and other problems, achieve energy density improvement, tight coordination, increase The effect of compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

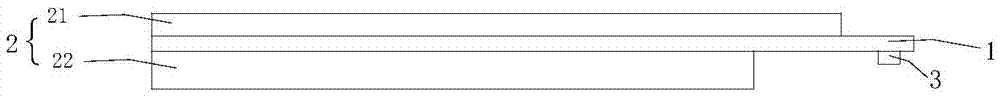

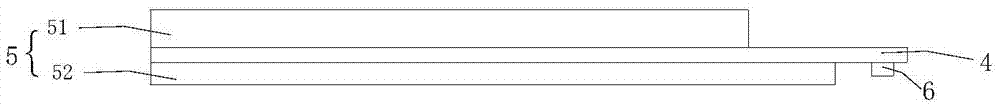

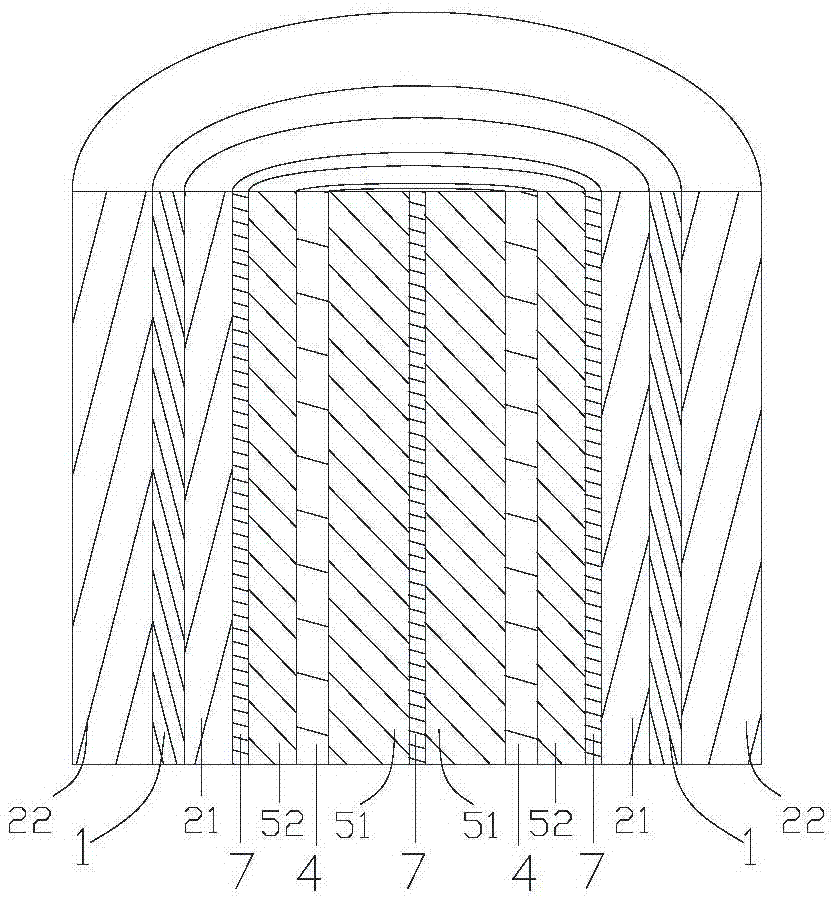

[0039] A kind of positive and negative plate of lithium ion battery, wherein, the electrode material of positive plate is lithium manganate according to mass ratio: the mixed positive electrode system that nickel cobalt manganese=3:7 forms, and positive plate comprises positive electrode current collector layer, positive electrode positive surface material layer and positive electrode cathode material layer; and the areal density of the electrode material of the positive electrode cathode material is 40% of the total electrode material areal density of the positive pole plate, and the areal density of the electrode material of the positive anode material is 40% of the total electrode material areal density of the positive pole plate 60%; the electrode material of the negative plate is a graphite system, and the negative plate includes a negative current collector layer, a negative anode material layer and a negative negative material layer; and the areal density of the electrode...

Embodiment 2

[0042] A lithium ion battery positive and negative plates, wherein the electrode material of the positive plate is a lithium cobaltate system, and the positive plate includes a positive current collector layer, a positive anode material layer and a positive negative material layer; and the electrode material of the positive anode material The areal density is 62% of the areal density of the total electrode material of the positive plate, and the areal density of the electrode material of the positive negative side material is 38% of the areal density of the total electrode material of the positive plate; the electrode material of the negative plate is a graphite system, and the negative plate includes Negative electrode current collector layer, negative electrode anode material layer and negative electrode negative surface material layer; And the areal density of the electrode material of the negative electrode anode material is 62% of the total electrode material areal density ...

Embodiment 3

[0045] A lithium ion battery positive and negative plates, wherein the electrode material of the positive plate is lithium cobaltate: nickel cobalt manganese=7.5:2.5 mixed material system, and the positive plate includes a positive current collector layer, a positive anode material layer and a positive negative material layer; and the areal density of the electrode material of the positive anode material is 58% of the total electrode material areal density of the positive pole plate, and the areal density of the electrode material of the positive pole cathode material is 42% of the total electrode material areal density of the positive pole plate; The electrode material is a graphite system, and the negative plate includes a negative electrode current collector layer, a negative anode material layer and a negative electrode negative material layer; and the areal density of the electrode material of the negative anode material is 58% of the total electrode material areal density ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com